In the world of construction and insulation, innovation is the key to building better, more energy-efficient structures. One such innovation that has been gaining widespread recognition is the EPS sandwich panel.

Whether you’re a seasoned builder or just embarking on your construction journey, understanding what EPS concrete sandwich panels are and their myriad advantages is essential.

In this article, we’ll delve into the fascinating world of EPS sandwich panel, exploring their composition, benefits, applications, and more. By the end of this read, you’ll have a comprehensive understanding of why EPS sandwich panels have become a popular choice in the construction industry.

So, let’s begin our journey into the world of EPS sandwich panels and discover how they can revolutionize your construction projects.

What Is EPS Sandwich Panel?

In the world of construction and insulation, EPS sandwich panels are a popular choice. They offer a cost-effective, energy-efficient, and versatile solution for a variety of applications.

EPS sandwich panel is a type of lightweight concrete wall material, which is a newly designed building material sandwich panel with thermal insulation, sound insulation, fireproofing, and seismic performance in the building industry.

Composition of EPS Sandwich Panels

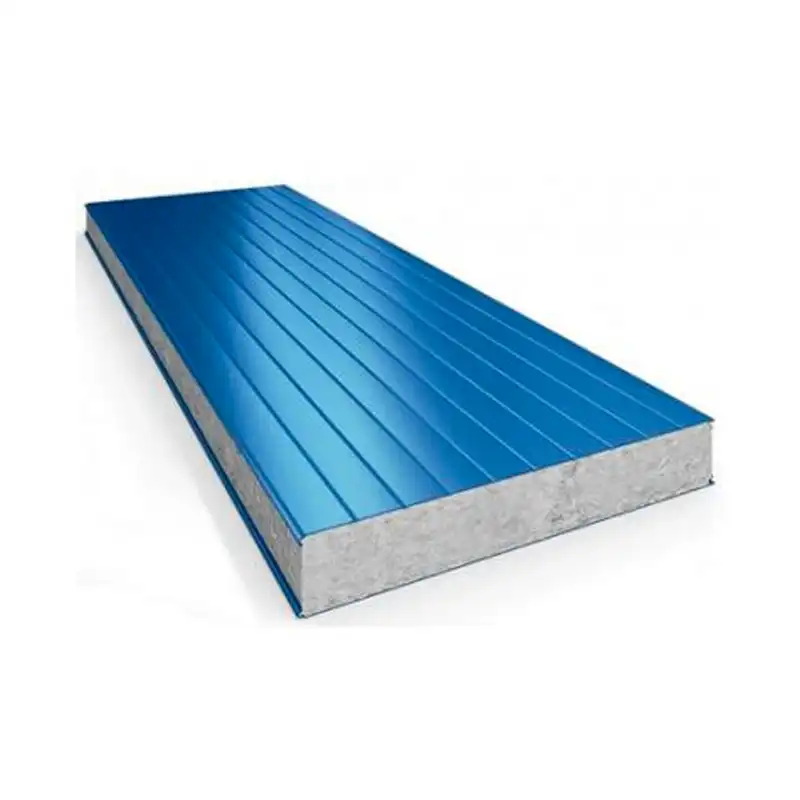

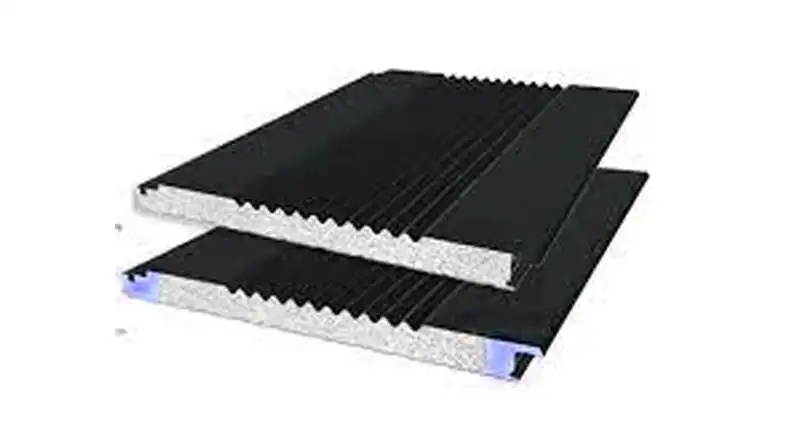

EPS stands for Expanded Polystyrene, a lightweight, rigid, and thermally efficient material. EPS sandwich panels consist of three main components:

- Facings: The outer layers of EPS panels, typically made of metal or other materials, which provide protection and durability.

- Core: The core is the heart of the panel and is made of expanded polystyrene foam. It provides excellent insulation properties and contributes to the panel’s lightweight nature.

- Adhesive: This layer binds the facings and the core together, ensuring structural integrity.

Advantages of EPS Sandwich Panels

Let’s delve further into the advantages of EPS sandwich panels:

- Outstanding Insulation Properties: EPS sandwich panels are renowned for their exceptional insulation capabilities. The core material, Expanded Polystyrene (EPS), is highly effective at maintaining temperature control. It helps keep buildings warm during the winter and cool in the summer, resulting in reduced heating and cooling costs. This thermal insulation is especially valuable in regions with extreme weather conditions.

- Lightweight Nature: One of the key advantages of EPS sandwich panels is their lightweight construction. The EPS core, despite its excellent insulation properties, is remarkably light. This not only simplifies the installation process but also reduces the overall load on the building’s structure. As a result, construction projects with EPS concrete panels are often completed faster and with lower labor costs.

- Cost-Effectiveness: When it comes to construction and operational expenses, EPS sandwich panels offer significant cost savings. The combination of quick installation, reduced labor requirements, and energy-efficient properties results in lower overall project costs. Additionally, the cost-effectiveness extends to long-term operational savings, as the panels contribute to lower energy bills.

- Swift Installation: Installing EPS sandwich wall panels is a swift and hassle-free process. Their lightweight nature, combined with interlocking designs, allows for rapid installation. This not only reduces labor expenses but also minimizes disruptions to ongoing operations in commercial or industrial settings.

- Energy Efficiency: The superior insulation properties of EPS wall panels make them a wise choice for those aiming to reduce their carbon footprint. By maintaining stable indoor temperatures, these panels contribute to the overall energy efficiency of a building. This not only benefits the environment but also results in lower energy consumption and associated costs.

- Durability: EPS sandwich panels are designed to withstand the test of time. The metal facings that encase the EPS core provide protection against external factors like weather, wear, and corrosion. This durability ensures that structures constructed with EPS wall panels have a longer lifespan, reducing the need for frequent repairs or replacements.

EPS sandwich panels offer a wide range of advantages, making them a preferred choice in construction. They provide excellent insulation, are lightweight, cost-effective, easy to install, and contribute to energy efficiency. Additionally, their durable construction ensures that the investment made in these panels is a lasting one, making them a compelling choice for various construction projects.

EPS Sandwich Panel Applications

EPS sandwich panels have found extensive applications in various sectors due to their versatility and numerous benefits. Here are some of the common applications of EPS sandwich panels:

Roofing: EPS sandwich panels are frequently used for roofing in commercial, industrial, and residential buildings. Their excellent insulation properties help maintain a comfortable indoor environment, while their lightweight nature reduces the load on the building’s structure.

Wall Cladding: These panels are an ideal choice for wall cladding. They not only provide insulation but also enhance the aesthetics of the building. The durable metal facings protect the structure and ensure a long-lasting and attractive exterior.

Cold Storage: Maintaining temperature control is essential in cold storage facilities, and EPS sandwich panels are well-suited for this purpose. They create a thermal barrier that keeps the internal environment at the required low temperature, ensuring the quality of stored goods.

Residential Construction: In recent years, EPS sandwich panels have gained popularity in residential construction. Their energy-efficient properties help homeowners save on heating and cooling costs. They are used for roofing and wall applications, contributing to more comfortable and eco-friendly homes.

Industrial Facilities: Industrial buildings, such as warehouses and manufacturing plants, often utilize EPS sandwich panels for roofing and cladding. The combination of insulation, durability, and cost-effectiveness makes them a smart choice for these applications.

Commercial Buildings: Retail outlets, offices, and other commercial buildings benefit from EPS sandwich panels for their roofing and cladding needs. The panels contribute to a comfortable indoor environment, helping businesses save on energy costs.

Agricultural Structures: Farmers and agricultural businesses use EPS sandwich panels for constructing various structures, including barns, poultry houses, and storage facilities. The panels provide insulation, which is crucial for protecting livestock and stored agricultural products.

Partition Walls: In interior construction, EPS sandwich panels are used as partition walls. They help divide spaces efficiently, while also providing sound and thermal insulation.

Prefab Structures: EPS panels are often a key component in prefab construction, where speed and efficiency are paramount. They are used in the construction of prefabricated houses, offices, and modular buildings.

Transportation: In the transportation industry, EPS sandwich panels are employed in the construction of refrigerated trucks and containers. Their insulation properties help maintain the required temperatures for transporting perishable goods.

Healthcare Facilities: Hospitals, clinics, and healthcare facilities benefit from EPS panels in maintaining controlled and comfortable indoor environments, which are critical for patient care and equipment storage.

Educational Buildings: Schools and educational institutions use EPS sandwich panels for roofing and cladding, ensuring energy efficiency and a comfortable learning environment

Installation and Maintenance

Installation of EPS Sandwich Panels:

The installation of EPS (Expanded Polystyrene) sandwich panels is a straightforward process, which adds to their appeal in the construction industry.

Here are the key steps involved in installing these panels:

- Surface Preparation: The first step is to prepare the surface where the EPS panels will be installed. This involves cleaning the substrate and ensuring it’s even and free from debris. The better the surface preparation, the more securely the panels will adhere.

- Measurement and Cutting: The EPS sandwich panels need to be accurately measured and cut to fit the specific dimensions of the area. Precise cutting ensures a snug fit and a professional finish.

- Adhesive Application: A suitable adhesive is applied to the substrate. This adhesive will bond the EPS panel to the surface. It’s essential to use the correct adhesive to ensure a strong and lasting bond.

- Panel Placement: The panels are then carefully placed onto the adhesive-covered substrate. It’s important to align the panels accurately to avoid any gaps or misalignments.

- Fixing and Fastening: Depending on the specific project, panels may be further secured with mechanical fasteners or screws. This added reinforcement ensures that the panels stay in place, especially in exterior applications exposed to wind and weather.

- Sealing and Joints: After the panels are installed, the joints and seams are sealed to create a seamless surface. This not only enhances the insulation properties but also provides a clean and attractive finish.

Maintenance of EPS Sandwich Panels:

One of the advantages of EPS sandwich panels is their low maintenance requirements. However, to ensure they continue to perform optimally and maintain their appearance, some basic maintenance is recommended:

- Regular Cleaning: Depending on the location and exposure to elements, cleaning the panels periodically is essential. This removes dirt, dust, and contaminants that can accumulate on the panel surfaces. A gentle wash with mild detergent and water is usually sufficient.

- Inspection: Periodic inspections are necessary to check for any damage, especially in exterior applications. Damaged panels should be promptly repaired or replaced to maintain the integrity of the building envelope.

- Sealant Checks: Check the seals and joints for any signs of wear or damage. If there are issues with the seals, they should be resealed to maintain the insulation properties.

- Repainting: In some cases, especially with metal-faced panels, repainting may be required to maintain the protective and aesthetic properties of the panels.

- Protection Against Physical Damage: In high-traffic areas or locations where there is a risk of physical damage, protective measures such as barriers or bumpers should be installed to prevent damage to the panels.

- Professional Inspection: For larger and more critical installations, it’s advisable to have periodic professional inspections to ensure that the panels continue to perform as intended.

Overall, EPS sandwich panels are relatively low-maintenance, and their durable construction ensures a long lifespan. Regular cleaning and inspections, as well as prompt repairs when necessary, are key to ensuring the longevity and performance of these panels in various construction applications.

Conclusion

In conclusion, EPS sandwich panels are an excellent choice for constructing energy-efficient and cost-effective buildings. Their superior insulation properties, ease of installation, and versatility make them a top choice in various applications.

By selecting the right type of EPS sandwich panels and using them in your construction project, you can achieve both energy savings and structural integrity.

FAQs

Are EPS sandwich panels suitable for residential construction?

Yes, they are increasingly used in residential construction for their energy efficiency and cost-effectiveness.

How long Do EPS sandwich panels last?

With proper maintenance, EPS panels can last for several decades.

Can EPS panels be used in extreme weather conditions?

Yes, they are suitable for use in extreme weather conditions due to their durable facings.

What are the environmental benefits of EPS panels?

EPS is recyclable and contributes to reducing the carbon footprint of buildings.