In industries where temperature control is critical, such as food storage, pharmaceuticals, and logistics, maintaining a stable environment is essential to preserve product quality and safety. Cold room panels are fundamental in cold storage facilities, providing efficient insulation and durability to maintain consistent low temperatures. With the right cold room panels, facilities can optimize temperature regulation, reduce energy consumption, and extend the lifespan of stored products.

This article explores how cold room panels contribute to efficient temperature control, the features that make them effective, and how they can be optimized for various cold storage applications.

What Are Cold Room Panels?

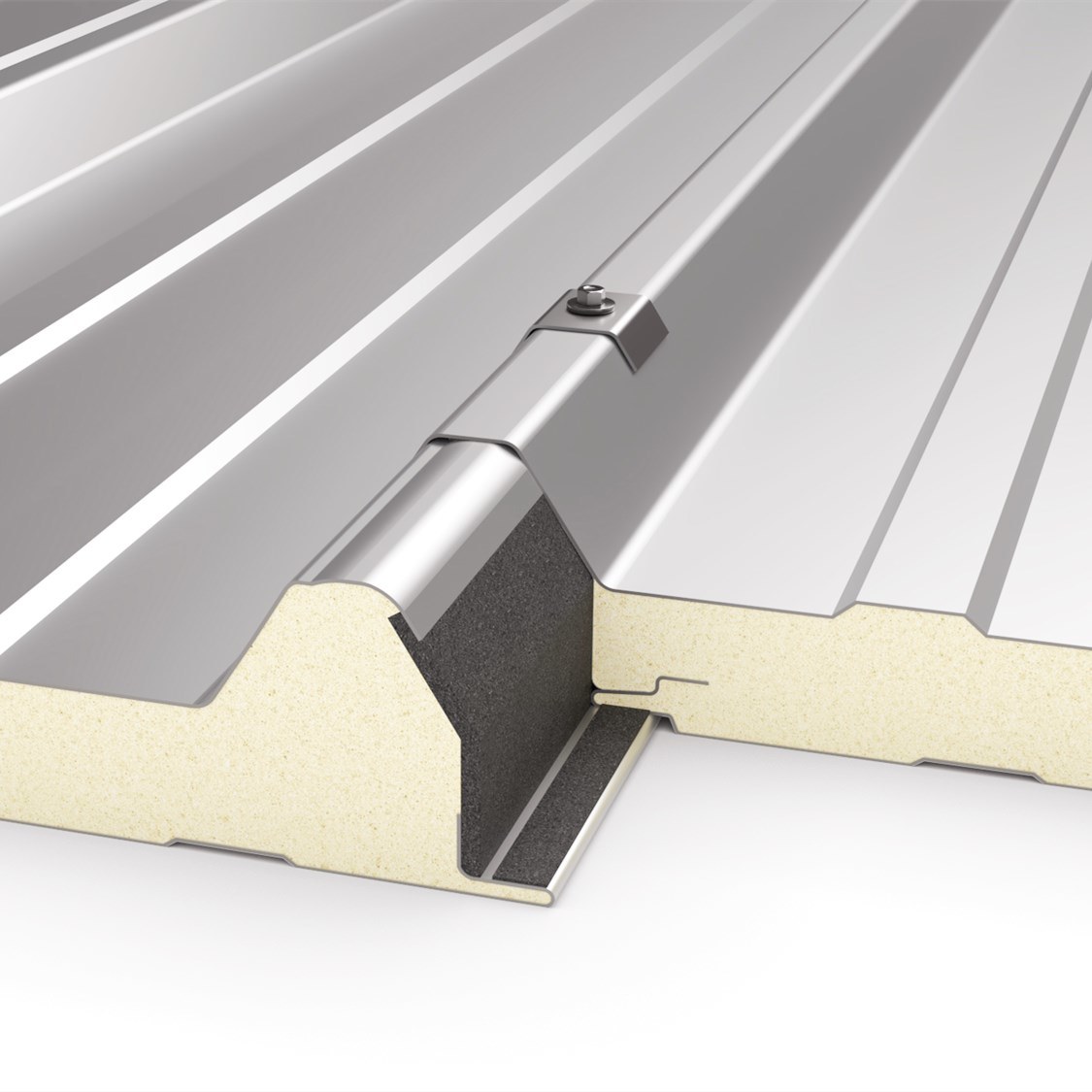

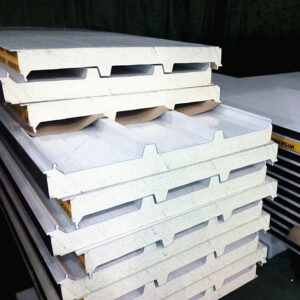

Cold room panels are specialized insulating panels designed for refrigerated and freezer rooms. They are typically made from high-quality insulating materials such as polyurethane (PU), polyisocyanurate (PIR), or expanded polystyrene (EPS), which provide excellent thermal insulation. These panels form the walls, ceilings, and floors of cold storage rooms, maintaining low temperatures and minimizing energy loss.

Cold room panels are an essential component in constructing efficient cold storage rooms, as they offer the insulation needed to preserve a stable, low-temperature environment. Their design also ensures durability and resistance to moisture, making them ideal for long-term use in demanding environments.

The Importance of Temperature Optimization in Cold Storage

In temperature-sensitive industries, fluctuations in storage temperature can lead to significant losses, impacting product quality, safety, and shelf life. Maintaining a stable temperature in cold rooms ensures that stored products, whether fresh produce, vaccines, or electronic components, are kept in optimal conditions.

Effective temperature control has numerous benefits, including:

- Product Longevity: Stable temperatures slow down product degradation, helping maintain quality and prolonging shelf life.

- Energy Efficiency: Efficient insulation reduces the workload on cooling systems, leading to lower energy costs.

- Compliance with Industry Standards: Cold storage facilities often must meet specific regulatory standards to ensure product safety, particularly in industries like food and pharmaceuticals.

By installing the right cold room panels, facilities can maintain precise temperature control, reduce operational costs, and ensure regulatory compliance.

Key Features of Cold Room Panels for Temperature Optimization

Cold room panels come with specific features that make them highly effective for temperature control. Here are some essential characteristics that contribute to their performance in cold storage applications:

1. High-Quality Insulating Materials

The core material of cold room panels is essential for thermal insulation. Common insulating materials include:

- Polyurethane (PU): Known for its excellent thermal resistance, PU offers efficient insulation, ensuring temperature stability in cold storage.

- Polyisocyanurate (PIR): PIR panels provide enhanced fire resistance and improved thermal insulation, making them suitable for facilities requiring higher safety standards.

- Expanded Polystyrene (EPS): EPS panels are cost-effective and provide good insulation, though they are typically used in less demanding environments.

The insulating properties of these materials allow cold room panels to maintain low temperatures with minimal energy consumption.

2. Airtight Sealing and Vapor Barrier

Cold room panels are designed with airtight joints and built-in vapor barriers to prevent air and moisture infiltration. Any breach in the panel seal can lead to temperature fluctuations, which compromise the cold room’s stability. Airtight sealing prevents warm air from entering the cold storage area, reducing the risk of condensation and frost buildup on products and equipment.

By blocking moisture, the vapor barrier also prevents mold growth, corrosion, and other issues that could affect product safety and equipment longevity.

3. Durable Construction

Cold room panels must withstand demanding conditions, such as frequent temperature changes, high humidity, and physical impacts. To ensure durability, panels are typically constructed with robust outer layers made from materials like galvanized steel or aluminum.

This durability is crucial in cold storage facilities where heavy equipment and high traffic are common. Strong outer surfaces protect the insulation from damage, preserving its efficiency and preventing costly repairs or replacements.

4. Fire Resistance and Safety

In addition to temperature control, safety is a priority in cold storage facilities. Some cold room panels, particularly those made from PIR, have built-in fire resistance. These panels help reduce the spread of flames in the event of a fire, providing an added layer of safety and meeting regulatory requirements.

Fire-resistant panels are particularly important in food processing, pharmaceuticals, and logistics sectors, where safety compliance is strictly enforced.

5. Customizable Thickness and Panel Sizes

Cold room panels are available in a range of thicknesses to suit specific temperature requirements. Thicker panels offer better insulation and are commonly used for freezer rooms, while thinner panels are often sufficient for cool rooms or ambient storage. Custom panel thicknesses allow facilities to optimize temperature control based on their unique storage needs, ensuring the right balance of insulation and cost-efficiency.

How Cold Room Panels Optimize Temperature Control

The efficient insulation provided by cold room panels plays a significant role in optimizing temperature control in cold storage facilities. Here’s how these panels contribute to consistent, energy-efficient temperature management:

1. Minimizing Temperature Fluctuations

With high-quality insulation, cold room panels minimize temperature fluctuations by trapping cold air inside the storage area and blocking external heat. Stable temperatures prevent rapid changes that could compromise product quality, such as the formation of ice crystals on food items or the degradation of temperature-sensitive pharmaceuticals.

2. Reducing Energy Consumption

Cold room panels provide excellent thermal insulation, which reduces the workload on cooling systems. The less frequently cooling systems have to operate, the more energy is saved, lowering operational costs. Efficient temperature control through insulated panels contributes to energy savings and supports sustainability goals.

3. Preventing Condensation and Frost

In cold storage environments, condensation and frost can damage products, affect equipment performance, and lead to frequent maintenance. The airtight sealing and vapor barrier of cold room panels prevent moisture from entering the storage area, thus reducing condensation and frost buildup. This protection is particularly crucial for facilities storing products that are se 6nsitive to moisture, such as electronics and perishable foods.

4. Enhancing Product Quality and Safety

Consistent temperature control provided by cold room panels preserves the quality, texture, and nutritional content of perishable goods. In pharmaceutical storage, stable temperatures protect the efficacy of vaccines, medications, and biological samples, which are highly sensitive to temperature changes. By maintaining optimal conditions, cold room panels play a vital role in product safety and regulatory compliance.

Industries that Benefit from Cold Room Panels

Several industries rely on cold room panels to ensure the quality and safety of temperature-sensitive products. Here are some sectors that benefit the most from high-quality, insulated cold room panels:

1. Food and Beverage Industry

In food processing, storage, and distribution, maintaining consistent low temperatures is essential to prevent spoilage and contamination. Cold room panels are used in various applications, including meat processing plants, dairy facilities, seafood storage, and frozen goods warehouses. By keeping temperatures stable, cold room panels help the food industry meet regulatory standards and extend product shelf life.

2. Pharmaceutical and Biotechnology

Pharmaceutical products, such as vaccines, biologics, and medications, are highly sensitive to temperature changes. In pharmaceutical cold storage, even slight temperature deviations can reduce drug efficacy or compromise safety. Cold room panels ensure precise temperature control, enabling safe storage for pharmaceuticals and laboratory samples, as well as regulatory compliance with standards like Good Distribution Practice (GDP) and Good Manufacturing Practice (GMP).

3. Logistics and Cold Chain Storage

In logistics, maintaining temperature control across the cold chain is essential for preserving the quality of perishable goods and pharmaceuticals. Cold storage facilities equipped with high-quality cold room panels ensure that products remain at the required temperature until they reach their final destination. By optimizing insulation, logistics companies reduce spoilage and maintain product integrity during transportation.

4. Floral and Horticulture Industry

Flowers and plants require specific temperature and humidity levels to retain their freshness and aesthetic appeal. Cold room panels provide the stable environment necessary to prevent premature wilting and extend the life of flowers. In the horticulture industry, cold room panels are used in storage facilities to maintain optimal conditions for various types of flowers, plants, and seeds.

5. Electronics and High-Tech Equipment Storage

Certain electronic components and high-tech equipment are sensitive to humidity and temperature fluctuations, which can lead to corrosion or electrical failures. Cold room panels help create a controlled environment for storing these products, ensuring they remain functional and in pristine condition. This application is common in the semiconductor, aerospace, and data center industries, where quality control is paramount.

Best Practices for Optimizing Cold Room Panels

To ensure maximum efficiency and longevity from cold room panels, it’s essential to follow best practices for installation and maintenance. Here are some recommendations:

1. Ensure Proper Installation

Professional installation is crucial for achieving optimal temperature control with cold room panels. During installation, ensuring that the panels are tightly sealed and joined correctly will prevent air leaks and maintain insulation integrity. Poor installation can lead to thermal bridging, where heat flows through gaps, undermining the cold room’s insulation.

2. Regularly Inspect and Maintain Seals

Over time, seals on cold room panels may wear down or become compromised. Regularly inspect seals and replace damaged ones to ensure airtight insulation. Proper maintenance helps prevent condensation, frost buildup, and energy loss, keeping the cold room’s performance consistent.

3. Use the Appropriate Panel Thickness

Choose cold room panels with the appropriate thickness based on the required storage temperature. For freezer rooms, thicker panels are typically more effective, as they provide enhanced insulation that minimizes energy use and temperature fluctuations. Consulting with a cold room expert can help determine the best panel specifications for each storage application.

4. Monitor Energy Use and Temperature Stability

Monitoring energy use and temperature stability helps identify any potential issues with the cold room’s insulation or cooling system. If energy consumption increases unexpectedly, it may be due to gaps or compromised insulation. Addressing these issues early can prevent temperature fluctuations and additional operational costs.

Why Choose Wise Link for Cold Room Panels?

Wise Link offers high-quality, customizable cold room panels tailored to meet the specific needs of various industries. With a focus on durability, insulation efficiency, and ease of installation, Wise Link’s cold room panels help businesses achieve optimal temperature control for their storage requirements. Here’s what sets Wise Link apart:

- High-Quality Materials: Our panels are made from top-grade insulating materials like PU, PIR, and EPS, ensuring long-lasting thermal resistance and durability.

- Custom Panel Thickness Options: We offer a range of panel thicknesses to suit different temperature needs, from chilled rooms to deep freezers.

- Professional Installation Support: Wise Link’s expert installation team ensures that your cold room panels are installed for maximum insulation and energy efficiency.

- Compliance with Safety Standards: Our panels meet industry standards for insulation and fire resistance, ensuring regulatory compliance in various sectors.

Optimizing Temperature Control with Cold Room Panels

Cold room panels are a crucial component for achieving efficient, consistent temperature control in cold storage facilities. With high-quality insulation materials, airtight sealing, and customizable thickness, cold room panels offer the durability and performance needed to maintain optimal storage conditions across diverse industries. Whether used in food storage, pharmaceuticals, or electronics, these panels ensure product integrity, energy efficiency, and regulatory compliance.

If you’re looking to optimize your cold storage facility with durable, high-performance cold room panels, Wise Link provides custom solutions that meet the highest industry standards. Contact us today to learn more about how our cold room panels can enhance your temperature control and protect your valuable products.

FAQs

- What materials are cold room panels made from?

Cold room panels are commonly made from insulating materials like polyurethane (PU), polyisocyanurate (PIR), and expanded polystyrene (EPS), each offering specific benefits for temperature control. - How do cold room panels prevent temperature fluctuations?

Cold room panels provide high-quality insulation that traps cold air inside the storage space and blocks external heat, minimizing temperature fluctuations and ensuring consistent cooling. - Why is airtight sealing important in cold room panels?

Airtight sealing prevents warm air and moisture from entering the cold room, reducing condensation, frost buildup, and energy waste, which are critical for maintaining stable temperatures. - Can cold room panels be used in freezer rooms?

Yes, thicker cold room panels with enhanced insulation properties are commonly used in freezer rooms to maintain ultra-low temperatures and reduce energy consumption. - What industries benefit from cold room panels?

Industries such as food and beverage, pharmaceuticals, logistics, horticulture, and electronics rely on cold room panels to maintain stable, temperature-controlled storage environments.

Maintain Optimal Temperature Control with High-Quality Cold Room Panels

Preserve Product Integrity and Save on Energy Costs with Custom Cold Room Panel Solutions. Contact Wise Link Today for a Free Consultation and Quote!