What Are the Most Effective Contamination Control Strategies in Modern Cleanrooms?

Written by Wiselink Group, Qingdao China

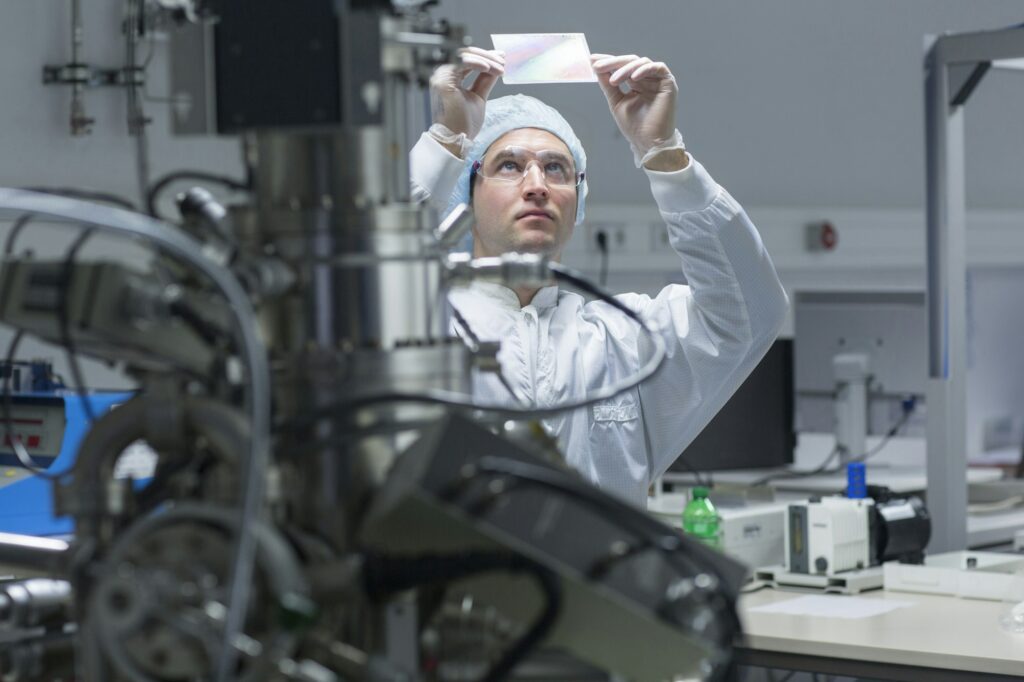

In today’s rapidly evolving industrial landscape, contamination control in cleanrooms has become more critical than ever. Whether in the pharmaceutical, biotechnology, semiconductor, or food industries, maintaining a contamination-free environment is essential to product quality, safety, and regulatory compliance. Cleanrooms are designed to minimize contamination risks, but it takes more than just a well-sealed environment to ensure air purity and sterility. It requires effective strategies, equipment, and ongoing maintenance that must work together in harmony to prevent contamination and optimize performance.

At Wiselink Group, we understand the complexities involved in contamination control and offer comprehensive solutions designed to meet the stringent requirements of modern cleanrooms. This blog will explore the most effective contamination control strategies in cleanrooms, including the role of design, air filtration, gowning protocols, and regular maintenance. It will also explain why Wiselink Group’s expertise and solutions make us the ideal choice for building and maintaining your cleanroom.

The Importance of Contamination Control in Cleanrooms

Contamination control is the cornerstone of cleanroom operations, as it directly affects the quality and safety of products. Cleanrooms are used to manufacture, assemble, and package products that require strict environmental conditions to prevent contamination by particles, microbes, or other harmful agents. The presence of contamination can lead to defects in products, safety hazards, and regulatory non-compliance, which can ultimately affect brand reputation and financial performance.

Effective contamination control is achieved through a combination of environmental design, equipment, operational procedures, and constant monitoring. Cleanrooms must not only maintain low levels of airborne particulates but also prevent contamination from surfaces, equipment, and personnel. Keeping a cleanroom in optimal condition requires ongoing effort, resources, and expertise to continuously meet these high standards.

Key Contamination Control Strategies

There are several strategies to control contamination in cleanrooms, each focusing on specific aspects of the cleanroom environment. Below, we’ll examine the most effective strategies that should be implemented to ensure contamination control.

1. Air Filtration Systems

One of the most essential aspects of contamination control is the air filtration system. Airborne particles can introduce contaminants into a cleanroom, which is why having a robust filtration system is crucial. The use of HEPA (High-Efficiency Particulate Air) and ULPA (Ultra-Low Penetration Air) filters is standard practice in cleanrooms to remove airborne particles and maintain high air quality. These filters trap particles as small as 0.3 microns and 0.12 microns, respectively, ensuring that harmful contaminants are filtered out before they can settle on surfaces or get into sensitive equipment.

In addition to HEPA and ULPA filters, cleanrooms also use laminar flow systems and airlocks to control air movement and prevent contamination from entering the cleanroom. Laminar flow provides a consistent and directional airflow that prevents contaminants from circulating within the room.

Why choose Wiselink Group for air filtration solutions?

At Wiselink Group, we offer the latest air filtration systems that are designed for superior performance, energy efficiency, and reliability. We ensure that the filtration systems we supply meet industry standards and are compatible with your cleanroom’s specific needs.

2. Cleanroom Design and Layout

The design and layout of the cleanroom play a significant role in minimizing contamination. Proper airflow, pressure differentials, and material flow are key factors in preventing cross-contamination. Cleanrooms are often designed with positive pressure zones to ensure that air flows outward, preventing contaminants from entering the controlled environment.

Zoning is another important design consideration. Critical areas such as manufacturing zones, packing areas, and storage rooms should be carefully segregated. Material handling areas, personnel spaces, and equipment storage should be strategically placed to minimize contamination risks. Additionally, laminar airflow hoods and dynamic pass boxes should be incorporated to ensure that air flows in a way that minimizes particle deposition.

Why Wiselink Group’s cleanroom design stands out?

Wiselink Group specializes in designing and constructing cleanrooms that meet your exact specifications. Our designs incorporate the latest technologies in air management and structural integrity to optimize contamination control. Whether you need modular or traditional cleanroom designs, we offer solutions that are flexible, scalable, and compliant with international standards.

3. Gowning Procedures and Personnel Protocols

Personnel are often the largest source of contamination in cleanrooms. As such, strict gowning procedures and personnel protocols are vital for contamination control. Employees must wear appropriate cleanroom clothing, such as gowns, gloves, masks, and shoe covers, to prevent the shedding of particles and microorganisms into the cleanroom environment.

Personnel should also be trained in proper gowning procedures and understand the importance of minimizing movement, avoiding unnecessary contact with surfaces, and not bringing in contaminants from outside the cleanroom. Gowning procedures should be followed at all times, and any breaches in protocol can lead to contamination risks.

How Wiselink Group supports gowning and personnel protocols?

We provide cleanroom gowns, gloves, masks, and other essential cleanroom products that are designed to meet the highest industry standards. Our products are made with materials that minimize the risk of contamination while offering comfort and durability. Additionally, we offer training and consultation services to ensure that your team follows best practices for contamination control.

4. Regular Cleaning and Maintenance

Cleanrooms must be cleaned regularly to ensure that they remain free of contaminants. However, cleanroom cleaning is a specialized task that requires specific protocols, equipment, and cleaning agents to maintain compliance with regulatory standards. Periodic cleaning should be performed on both horizontal and vertical surfaces, including floors, walls, ceilings, and equipment.

Cleaning protocols should include the use of non-abrasive cleaning agents that will not introduce additional particles or chemical residues into the environment. High-efficiency cleaning equipment, such as microfiber cloths, HEPA vacuum cleaners, and air scrubbers, should also be used.

Why choose Wiselink Group for cleaning solutions?

We offer professional cleanroom maintenance services that help you maintain your cleanroom to the highest standards. Our cleaning products, tools, and techniques are designed to remove particles without causing damage to sensitive surfaces. Our expert team ensures that your cleanroom remains compliant, safe, and ready for operation.

5. Monitoring and Continuous Evaluation

One of the most effective strategies for contamination control is continuous monitoring. Cleanroom monitoring systems track critical parameters such as temperature, humidity, airflow, and particulate levels. Real-time monitoring ensures that any deviations from set standards are detected immediately, and corrective action can be taken before contamination risks escalate.

Data analytics and automated systems allow for the efficient management of cleanroom conditions. By continuously assessing environmental conditions and tracking trends over time, cleanroom managers can maintain a sterile environment and optimize their processes.

Why Wiselink Group excels in monitoring solutions?

Our smart monitoring solutions allow for real-time data collection and analysis, providing actionable insights that help you maintain contamination control. Our monitoring systems integrate seamlessly with other cleanroom technologies and can be customized to meet your specific needs.

Conclusion: Why Choose Wiselink Group for Your Cleanroom Contamination Control Needs?

Contamination control is an ongoing challenge that requires a combination of design, equipment, and procedures. By integrating advanced filtration systems, optimal cleanroom design, strict gowning protocols, regular cleaning, and continuous monitoring, you can ensure that your cleanroom remains a safe and sterile environment for production.

At Wiselink Group, we are dedicated to providing top-tier cleanroom solutions that meet the highest standards of contamination control. From modular cleanrooms to advanced filtration systems, we offer everything you need to maintain a contamination-free environment. Our experience, expertise, and commitment to quality make us the ideal partner for your cleanroom design and maintenance need