Understanding the Science Behind Cleanroom Ventilation and Air Exchange Rates

Written by Wiselink Group, Qingdao China

Cleanrooms are essential in various industries, including pharmaceuticals, biotechnology, electronics, and aerospace, where even the smallest particle contamination can significantly impact product quality and safety. For such environments to function effectively, maintaining optimal air quality is crucial, which is where cleanroom ventilation and air exchange rates come into play. The ventilation system in a cleanroom controls the air’s quality, temperature, humidity, and pressure, ensuring the controlled environment meets the necessary cleanliness standards. Understanding the science behind cleanroom ventilation and air exchange rates is crucial for industries that rely on these controlled environments. In this blog, we will dive deep into the essential elements of cleanroom ventilation systems, the role of air exchange rates, and how these factors work together to maintain a contamination-free environment.

What is Cleanroom Ventilation?

Cleanroom ventilation refers to the process of regulating the airflow in a cleanroom to ensure that the environment remains free from airborne contaminants. This includes controlling the air quality, temperature, humidity, and pressure, which are all critical elements for maintaining the cleanliness and sterility of the cleanroom. Ventilation systems are designed to replace the air in a cleanroom frequently, ensuring that any contaminants present are flushed out and replaced with clean, filtered air.

The ventilation system is responsible for introducing clean air into the room and ensuring that the airflow is directed in a way that minimizes the risk of particle contamination. High-efficiency particulate air (HEPA) or ultra-low particulate air (ULPA) filters are commonly used to ensure that the air entering the cleanroom is free of particles larger than a specific size. The effectiveness of a cleanroom ventilation system is crucial for maintaining product safety, regulatory compliance, and the overall integrity of the environment.

The Science Behind Air Exchange Rates

The air exchange rate (ACH) refers to the number of times the total volume of air in a cleanroom is replaced with fresh air within a given period, usually measured per hour. It is one of the most critical parameters in cleanroom design and operation because it directly impacts the cleanroom’s ability to maintain a contaminant-free environment. The air exchange rate is often determined by the class of cleanroom required, with stricter environments requiring higher air exchange rates.

For instance, ISO Class 1 cleanrooms, which require extremely low levels of particulate matter, may need an air exchange rate of 500 or more air changes per hour. In contrast, lower-class cleanrooms may have an air exchange rate of around 60 to 80 air changes per hour. The key to a successful ventilation system lies in ensuring that the correct number of air exchanges occurs at the right intervals to maintain the desired cleanliness level.

How Air Exchange Rates Affect Cleanroom Performance

Air exchange rates are critical to ensuring that particles do not build up within the cleanroom. Airborne particles, whether they are dust, microbes, or other contaminants, can compromise the quality and safety of products manufactured in cleanrooms. High air exchange rates help to remove these particles quickly and efficiently.

A high air exchange rate can help dilute and flush out contaminants that might enter the cleanroom due to human activity, equipment, or materials. Additionally, proper ventilation can ensure the uniform distribution of clean air throughout the space, preventing the accumulation of particles in specific areas. A well-designed air exchange system can help maintain consistent air quality, ensuring that the cleanroom meets the required contamination levels for the specific industry it serves.

In cleanroom operations, it is essential to balance the air exchange rate with the required airflow velocity. High air exchange rates may lead to higher energy consumption, making it important to design an efficient system that maintains the cleanliness of the environment while optimizing energy use.

The Role of Airflow Direction and Design in Cleanrooms

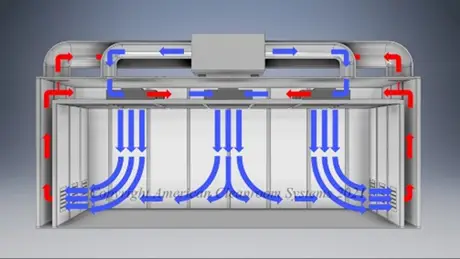

While air exchange rates are vital, the design and direction of airflow are equally important in cleanroom ventilation. Cleanrooms are generally designed to use unidirectional (laminar) airflow, meaning that air moves in a constant direction across the entire cleanroom, minimizing turbulence and preventing the mixing of contaminated and clean air. The air is typically introduced through a ceiling-mounted air distribution system and then directed toward the floor, where it is exhausted.

The direction and velocity of airflow must be carefully considered during cleanroom design to ensure that contaminants are carried away from sensitive areas. For instance, areas where materials are being processed or sensitive equipment is used should be protected from contaminants. Cleanroom ventilation systems are designed to maintain a positive pressure differential compared to surrounding areas, preventing the entry of airborne contaminants from outside. Negative pressure areas may also be used in certain applications, such as isolating potentially contaminated materials or hazardous substances.

Why Choose Wiselink Group for Your Cleanroom Ventilation Needs

Wiselink Group, based in Qingdao, China, offers a range of cleanroom solutions designed to meet the stringent demands of modern industries. With over 15 years of experience in cleanroom construction and solutions, Wiselink Group provides high-performance cleanroom systems that are tailored to your specific needs. We understand that cleanroom performance relies heavily on effective ventilation systems, and that’s why we offer cutting-edge technologies designed to maintain optimal air quality, air exchange rates, and airflow distribution.

Our cleanroom solutions include:

- Custom Cleanroom Design: We work closely with clients to design cleanrooms that meet their specific industry requirements, ensuring that ventilation systems are optimized for efficiency and cleanliness.

- High-Performance Ventilation Systems: Our cleanroom ventilation systems are designed with HEPA and ULPA filtration, ensuring that the air entering your cleanroom is free of particles and contaminants.

- Energy-Efficient Solutions: Wiselink Group emphasizes energy efficiency in cleanroom design. Our ventilation systems are engineered to provide the necessary airflow while minimizing energy consumption, helping you reduce operational costs.

- Compliance and Quality: Our cleanrooms are built to comply with international standards, such as ISO 14644, ensuring that your facility meets the highest quality and contamination control requirements.

If you are looking for a reliable partner to design and install an efficient cleanroom ventilation system, Wiselink Group is your trusted solution provider. With our years of expertise and commitment to quality, we can help you achieve the highest levels of air quality and contamination control. Contact us today to learn more about our cleanroom solutions and how we can support your industry’s needs.