The air shower is a necessary channel for people or materials to enter and exit the clean area, and plays the role of air lock and purification. It uses a blower to extract the circulating air inside the air shower, and after being filtered and purified by the primary and high-efficiency filters, the clean air is sprayed from the nozzle to the surface of people and materials at a high speed, and quickly removes dust particles and bacteria from the surface of personal clothing or materials. The blown dust particles and bacteria are absorbed and contained in the primary and high-efficiency filters through the circulating airflow.

It can reduce the pollution problems caused by entering and exiting the clean area, prevent the staff from bringing hair, dust, and bacteria into the clean workshop, which is conducive to maintaining the strict dust-free cleanliness level of the workplace and producing high-quality products.

It is widely used in various industrial sectors and scientific laboratories such as electronics, national defense, precision instruments, instrumentation, automobile manufacturing, pharmaceuticals, food, chemicals, agriculture, biology, etc.

| Model | SL-1150-1 | SL-1300-1 | SL-1300-15 |

|---|---|---|---|

| Dimensions (mm) | 1150x1000x2050 | 1300x1000x2050 | 1300x1500x2050 |

| Internal Size (mm) | 800x920x1900 | 800x920x1900 | 800x1420x1900 |

| Air Speed (m/s) | ≥25 | ≥25 | ≥25 |

| Nozzles | 6 | 12 | 18 |

| Power Supply | 380V, 50Hz | 380V, 50Hz | 380V, 50Hz |

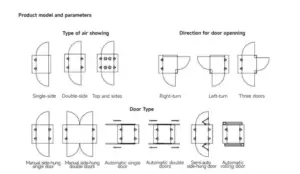

| Consumption (kW) | 0.65 | 1.3 | 2.4 |

The Air Shower is designed with scalability in mind, making it suitable for a wide range of industries and operational scales. Its customizable configurations, including adjustable air speeds, door types, and sizes, allow it to cater to both small cleanrooms and large industrial facilities. The automated interlocking system and voice prompts simplify operations for various user levels, reducing the need for intensive training. Moreover, the air shower’s ability to integrate with existing cleanroom systems ensures seamless scalability as facilities expand. Whether used for personnel or material entry, the air shower maintains consistent performance, meeting the demands of diverse workflows.

The Air Shower is indispensable in maintaining cleanliness and hygiene standards across multiple industries:

These applications highlight the versatility and necessity of air showers in contamination-sensitive industries.

The Air Shower offers advanced functionalities to ensure contamination control:

These functions make the air shower an essential tool for maintaining high-cleanliness environments.

Wise Link is synonymous with high-quality cleanroom solutions, and the Air Shower exemplifies their commitment to excellence. Constructed from premium SUS stainless steel, it offers durability, corrosion resistance, and sleek aesthetics. Advanced filtration systems, including HEPA filters, ensure top-notch air purification. The air shower’s automated features, such as voice prompts and interlocking systems, reflect Wise Link’s dedication to innovation and user convenience. Every unit undergoes rigorous quality checks to meet global standards, making Wise Link products a trusted choice for industries worldwide.

Wise Link’s main products include clean room panels, clean room Aluminum frame/steel frame doors, clean room double glass windows, clean room dynamic pass boxes, FFU, clean room LED light, and so on.