Importing Aluminium Sandwich Panel From China for Your Construction Project

Are you still looking for the Aluminium sandwich panel? Here we can provide the most competitive Aluminium sandwich panels, varied with different lengths, thickness and etc.

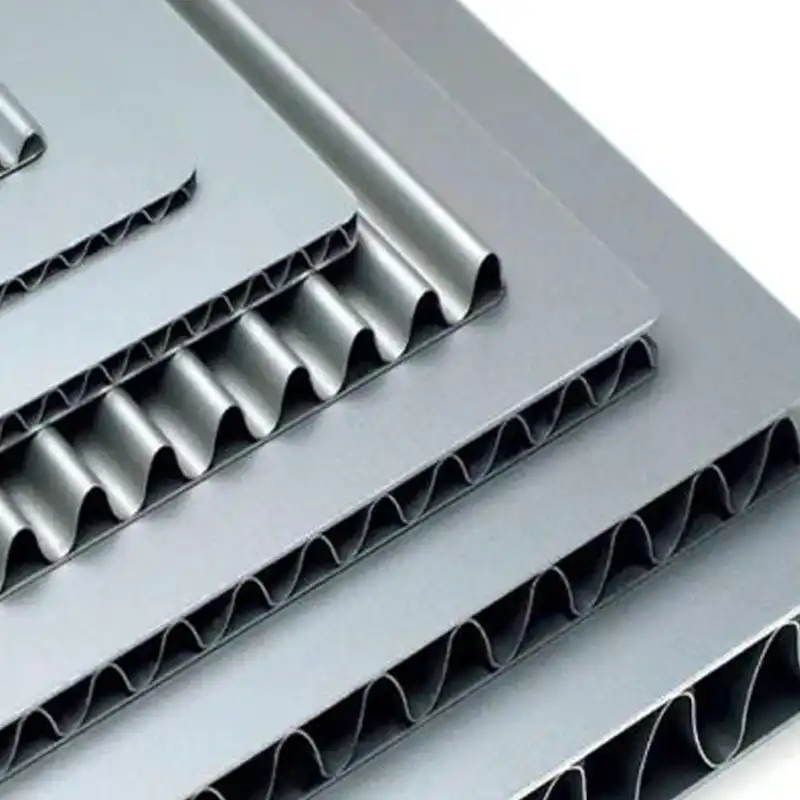

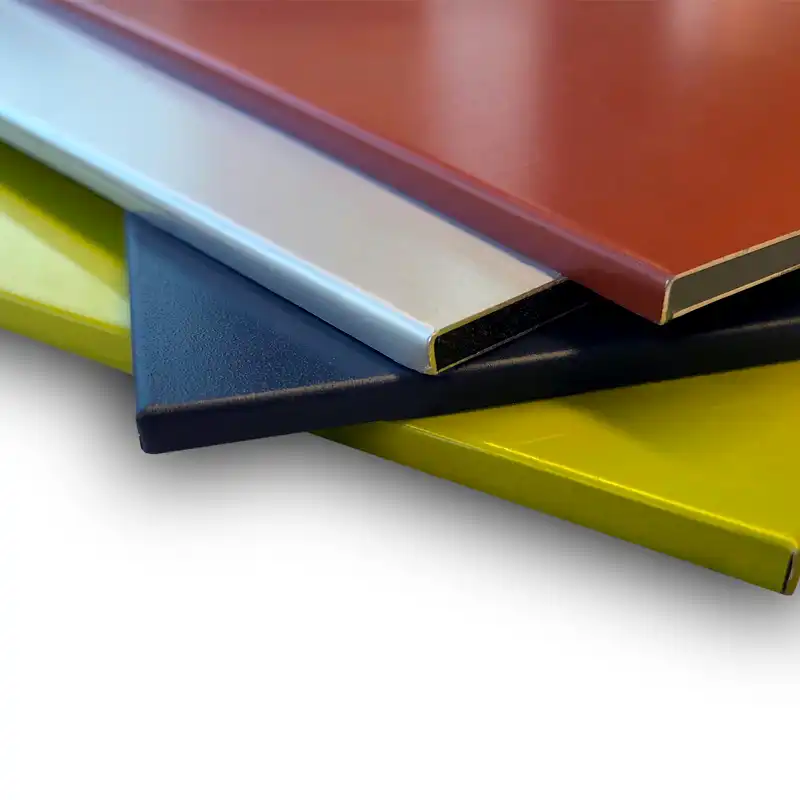

Aluminium sandwich panel constructure

Materials Preparation:

Aluminum sheets for outer layers.

Core material (polyethylene foam, polyurethane foam, or aluminum honeycomb).

Bonding Layers:

Aluminum layers bonded to each side of the core.

Adhesive (epoxy or polyurethane) used for bonding.

Pressing and Curing:

High-pressure pressing for uniform thickness.

Curing process for enhanced strength and stability.

Cutting and Shaping:

Precision cutting for desired sizes and shapes.

Finishing:

Additional treatments or coatings for UV resistance, aesthetics, and protection.

Edge treatments for a polished look.

Aluminium sandwich panel Benefits

Lightweight Construction:

- Aluminum sandwich panels are exceptionally lightweight, reducing the overall weight of structures. This is advantageous for both transportation and installation.

High Strength:

- Despite their lightweight nature, these panels offer high strength and durability. They contribute to the structural integrity of buildings without adding excessive weight.

Thermal Insulation:

- The core materials in aluminum sandwich panels provide effective thermal insulation. This feature helps regulate indoor temperatures, enhancing energy efficiency and reducing heating or cooling costs.

Versatility in Applications:

- Aluminum sandwich panels find versatile applications in construction, including wall cladding, roofing, and façade systems. Their adaptability makes them suitable for a wide range of architectural designs.

Aesthetic Customization:

- Panels can be customized in terms of color, finish, and texture to meet aesthetic preferences. This allows for a visually appealing and architecturally harmonious appearance.

Weather Resistance:

- The outer layers of aluminum provide excellent resistance to weather elements, including rain, UV radiation, and temperature fluctuations. This makes the panels suitable for outdoor use in various climates.

Easy Installation:

- Aluminum sandwich panels are relatively easy to install. Their lightweight nature simplifies handling, and they often feature interlocking mechanisms or simple fastening systems for efficient installation.

Low Maintenance Requirements:

- These panels generally require minimal maintenance. Regular cleaning and inspections for damage are typically sufficient to ensure long-term performance.

Fire Resistance Options:

- Depending on the specific composition and coatings, aluminum sandwich panels with fire-resistant properties are available. This is crucial for meeting safety standards in building construction.

Environmentally Friendly:

- Aluminum is recyclable, making the panels environmentally friendly. The recyclability of the material contributes to sustainability in construction practices.

Cost-Effective:

- The combination of lightweight construction, ease of installation, and low maintenance makes aluminum sandwich panels cost-effective over their life cycle, offering value for both initial investment and long-term use.

Sound Insulation:

- Some core materials used in these panels provide sound insulation properties, reducing the transmission of noise and contributing to a quieter indoor environment.

Trending Aluminium sandwich panels

Here we are one of the leading sandwich panel manufacturers from China, with the ability to provide the qualified Aluminium core sandwich panels. We can provide all kinds of the composite sandwich panels Aluminum, varied in different lengths, shapes, thickness and etc.

Here are trending Aluminium sandwich panels in the following, and welcome to contact us at any time if you are willing to get aluminium sandwich panel price.

aluminium foam sandwich panels

Here we can provide the Aluminium foam sandwich panels, with competitive prices and ensure the good quality at the same time. Flexible to customize your desired Aluminum foamed sandwich panels for your private projects, for more, please feel free to contact us now.

aluminium honeycomb sandwich panel

An aluminum honeycomb sandwich panel is a composite material structure, consisting of three main components: two outer layers of aluminum sheets and a core made of aluminum honeycomb. This design creates a lightweight yet strong panel with a variety of applications in industries such as aerospace, transportation, and construction.

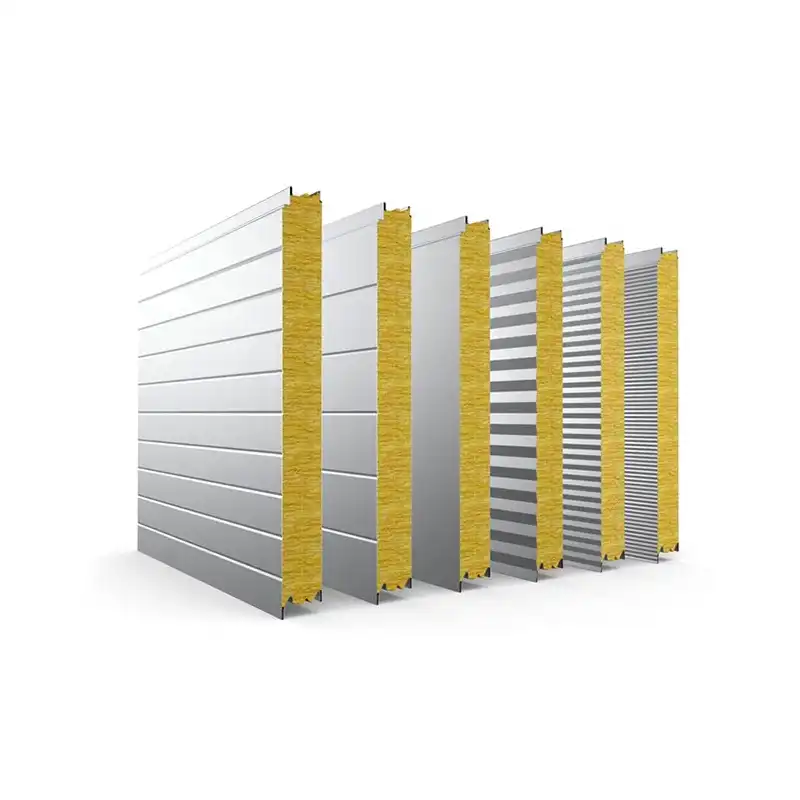

aluminium insulated sandwich panels

Upgrade your construction projects with the innovative solution of Aluminum Insulated Sandwich Panels. These panels combine the strength of aluminum with advanced insulation technology, delivering a perfect synergy of durability, energy efficiency, and aesthetic appeal.

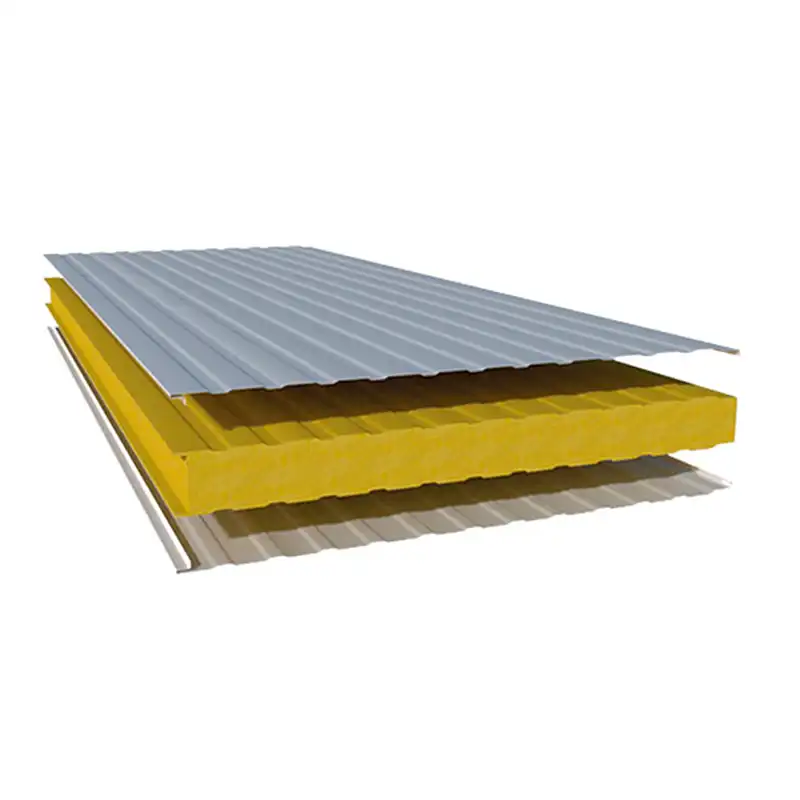

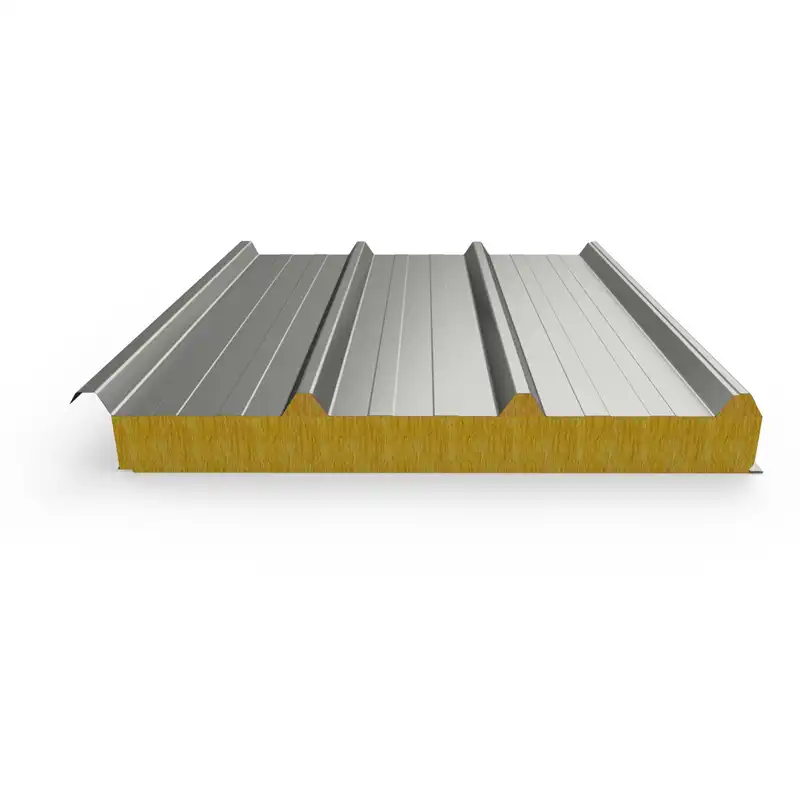

aluminium sandwich panel roof

Get premium Aluminium sandwich panel roof with different lengths, thicknesses, to build your own house. From raw material to packaging, we focus on each step of manufacturing sandwich panels, and welcome to contact us at any time if you are interested in.

aluminium composite sandwich panel

The Aluminium composite sandwich panels (ACP) are widely applied for many industries, including construction, building materials, and etc. We can customize all types of the composite Aluminium sandwich panels to meet your requirement for your projects.

aluminium sandwich panel door

We also can customize the sandwich panel door using the Aluminium sandwich panel for various construction projects. If you want to know more about the industry doors within the scope of our business, please be free to contact us at any time.

What is an aluminum sandwich panel?

An aluminum sandwich panel is a composite material comprising two outer layers of aluminum and a core material, such as polyethylene foam or aluminum honeycomb, sandwiched in between.

What are the key advantages of aluminum sandwich panels?

Aluminum sandwich panels are known for their lightweight nature, high strength, insulation properties, and versatility. They are widely used in construction for applications like wall cladding and roofing.

What is the purpose of the core material in the panel?

The core material provides structural support and insulation. Different core materials offer varying levels of strength, thermal resistance, and weight characteristics.

Where are aluminum sandwich panels commonly used?

These panels are commonly used in the construction industry for exterior cladding, roofing, and façade systems. They are also employed in applications requiring a combination of strength and low weight.

How are aluminum sandwich panels installed?

Installation methods vary, but panels are often secured to a supporting structure using mechanical fasteners. Proper installation is crucial to ensure stability and longevity.

Are aluminum sandwich panels environmentally friendly?

Aluminum is recyclable, making the panels eco-friendly. However, the environmental impact also depends on the manufacturing process and the disposal/recycling of the panels at the end of their life cycle.

Can aluminum sandwich panels be customized in terms of color and finish?

Yes, these panels can be coated or finished in various colors and textures to meet aesthetic preferences. Customization options depend on the manufacturer.

How do aluminum sandwich panels compare to traditional building materials?

Compared to traditional materials, aluminum sandwich panels offer a good balance of strength and weight, making them a popular choice for modern construction due to their efficiency and versatility.

Are aluminum sandwich panels fire-resistant?

The fire resistance of these panels depends on the specific composition and coatings. Some panels are available with fire-resistant properties, meeting safety standards. It’s essential to check with manufacturers for specific product details.