Importing Carbon Fiber Sandwich Panel From China

Are you looking for the wholesale carbon fiber sandwich panel from China? Here we are the leading sandwich panel supplier to provide you the most competitive sandwich panels with the premium rated quality. For more, please feel free to contact us at any time if you are interested in.

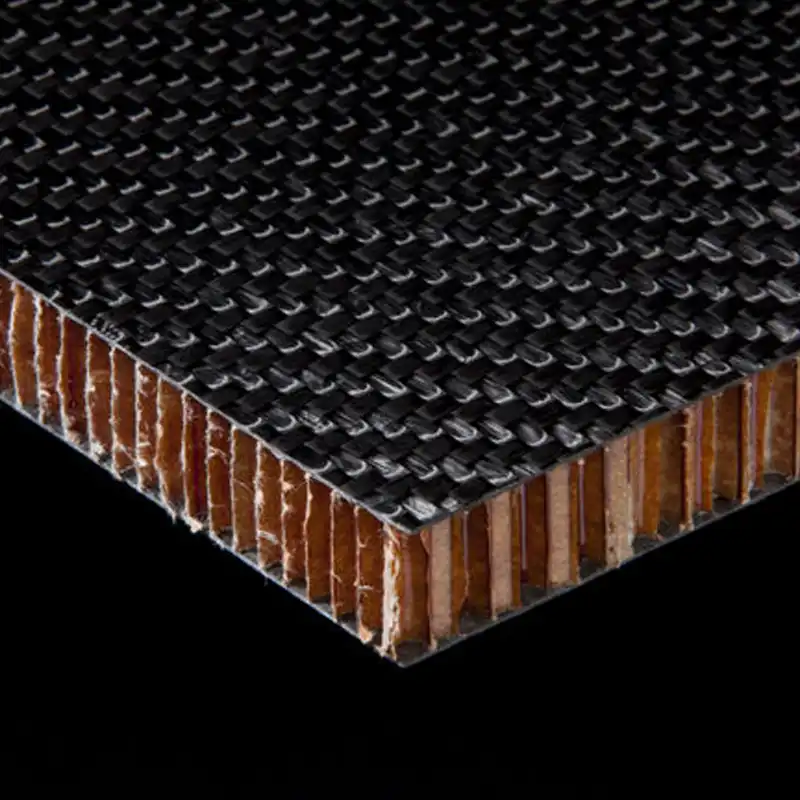

carbon fiber sandwich panel structure

Outer Layers (Skins):

Material: Carbon fiber-reinforced composites.

Resin Matrix: Typically epoxy.

Fabrication: Autoclave curing, resin infusion, or prepreg layup.

Core Material:

Material: Foam (PVC, foam), honeycomb (aluminum, Nomex), or balsa wood.

Function: Enhances stiffness, strength, and overall rigidity.

Bonding:

Adhesive: High-performance adhesives ensure a strong connection.

Manufacturing: Careful bonding of outer layers to the core under controlled conditions.

Carbon Fiber sandwich panels

The carbon fiber sandwich panel is the composite sandwich panel, that consists of carbon fiber reinforcement, and this type of sandwich panel building material can provide

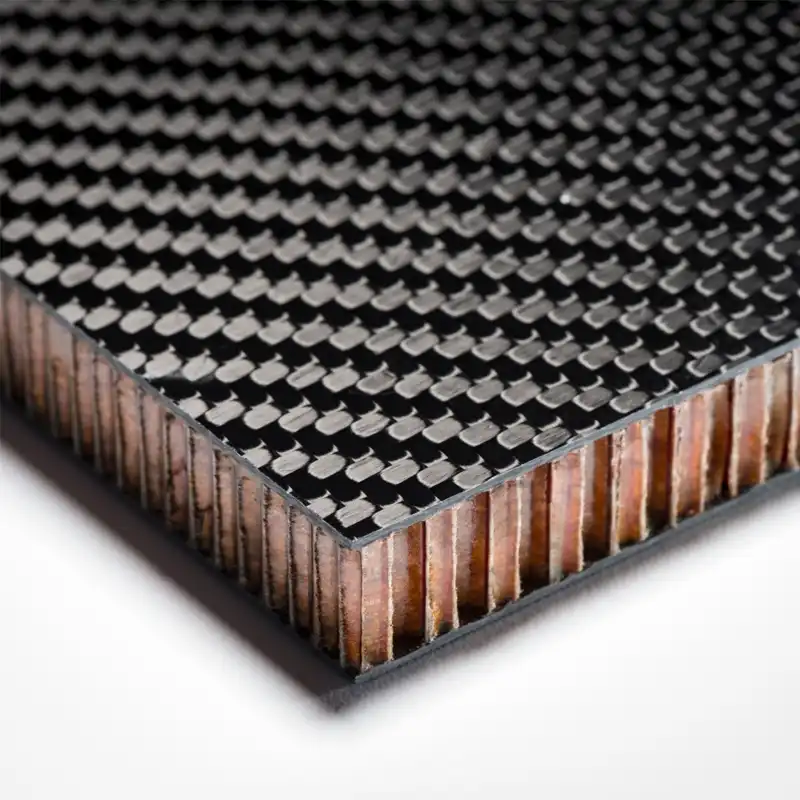

carbon fiber honeycomb sandwich panel

Are you in search of a carbon fiber honeycomb sandwich panel for your project? We can provide a high-quality carbon fiber core sandwich panel, featuring carbon fiber, to assist you in efficiently constructing a house.

carbon fiber aluminum honeycomb sandwich panel

We can provide the carbon fiber Aluminum honeycomb sandwich panels to ensure the best quality, and we can support the sandwich panel customization service to achieve your desired sandwich panels for your projects.

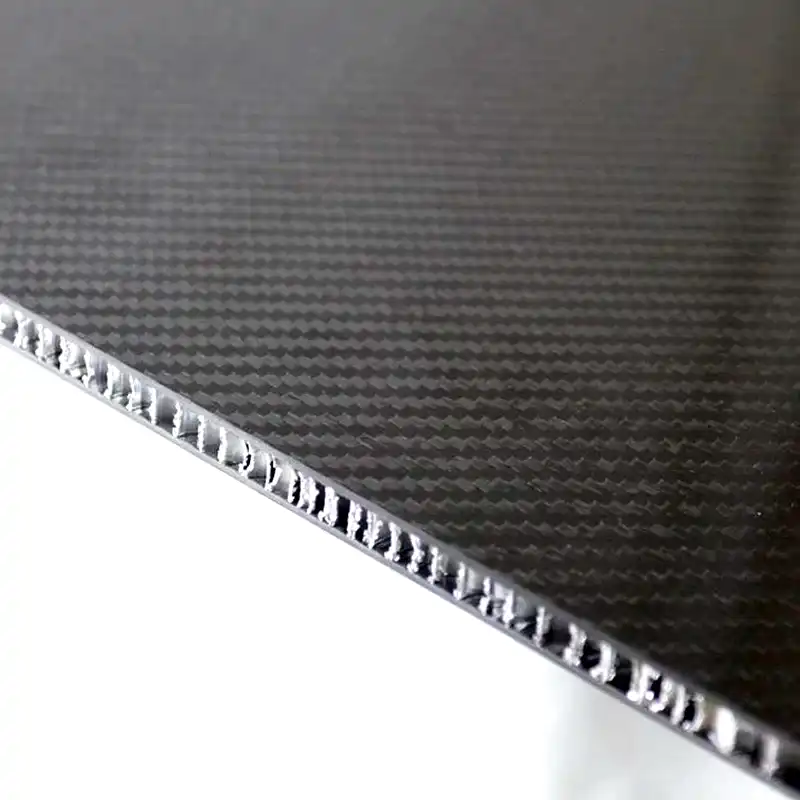

carbon fiber foam sandwich panel

We have a wide range of sandwich panels, and we can customize the carbon fiber sandwich panels to meet your requirements. Different lengths, thicknesses are supported to provide to meet your requirement for your projects.

what is carbon fiber sandwich panel

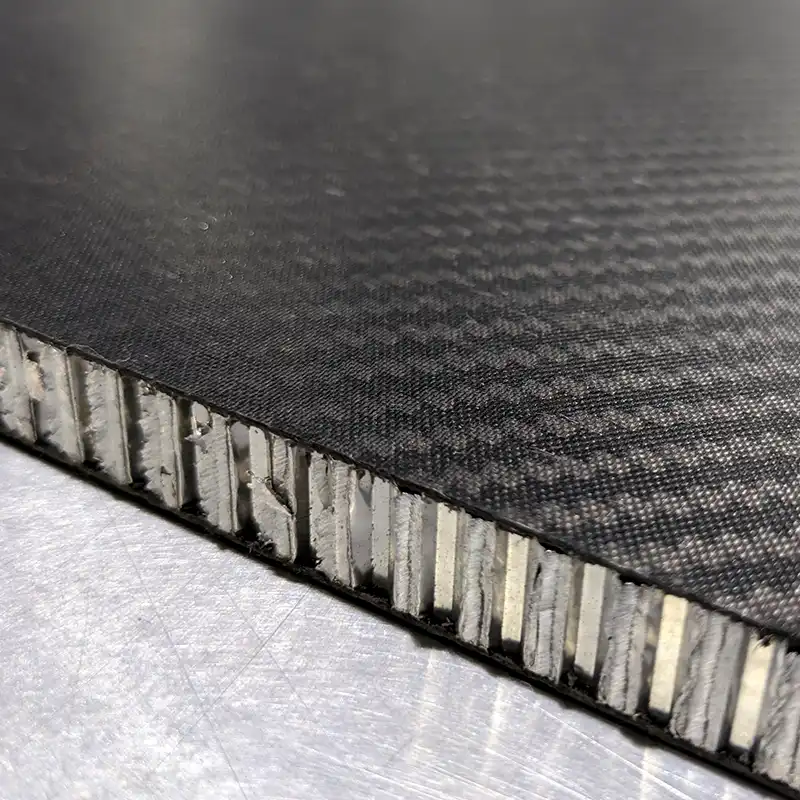

A carbon fiber sandwich panel is a composite structure consisting of two outer layers (skins) made of carbon fiber-reinforced composites with a core material sandwiched between them. This design provides a balance of strength and low weight.

What are the key components of a carbon fiber sandwich panel?

The key components include outer layers made of carbon fiber-reinforced composites, a core material (foam, honeycomb, or balsa wood), and high-performance adhesives for bonding.

What are the advantages of using carbon fiber sandwich panels?

The advantages include a high strength-to-weight ratio, stiffness, durability, and reduced overall weight. These panels are widely used in aerospace, automotive, marine, and construction industries for their exceptional performance.

How is a carbon fiber sandwich panel manufactured?

Manufacturing involves processes like autoclave curing, resin infusion, or prepreg layup. The outer layers are carefully bonded to the core material using high-performance adhesives under controlled conditions.

Are carbon fiber sandwich panels recyclable?

Recycling carbon fiber composite materials, including sandwich panels, can be challenging due to the complex nature of the composite structure. However, ongoing research aims to develop more sustainable and recyclable options for carbon fiber composites.

What are the typical applications of carbon fiber sandwich panels?

Carbon fiber sandwich panels are used in aerospace for aircraft components, in automotive for lightweight body parts, in marine for boat hulls and decks, and in construction for structural elements that require both strength and reduced weight.