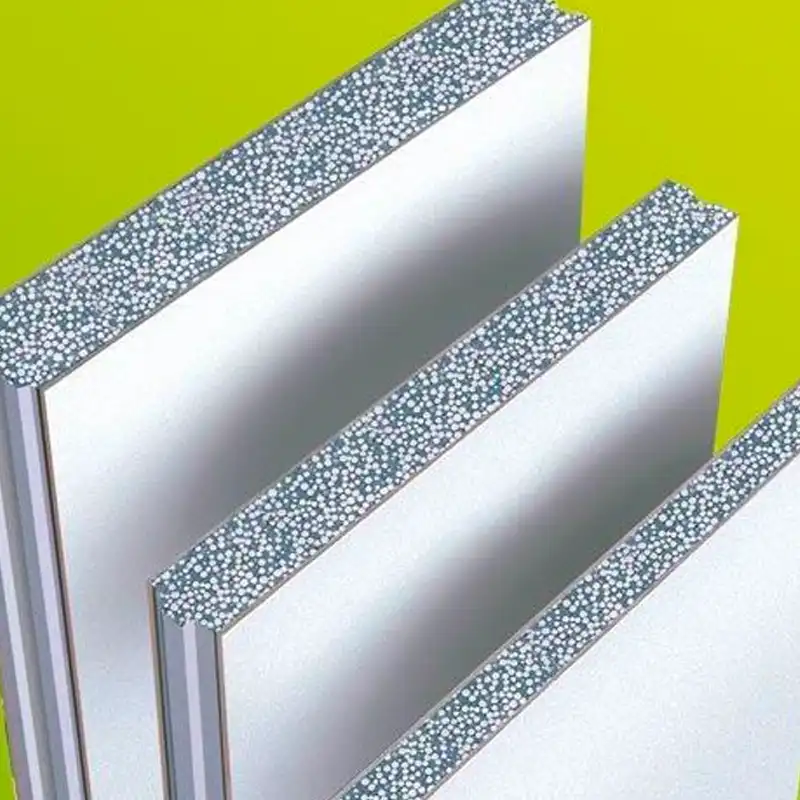

Importing Cement Sandwich Panel From China with Affordable Price

Are you looking for the cement sandwich panel? Here we can provide wholesale cement sandwich panels for your construction projects. You can choose to customize the cement sandwich panels to satisfy your desired thickness, length and etc. Quote us now to get

EPS cement sandwich panel

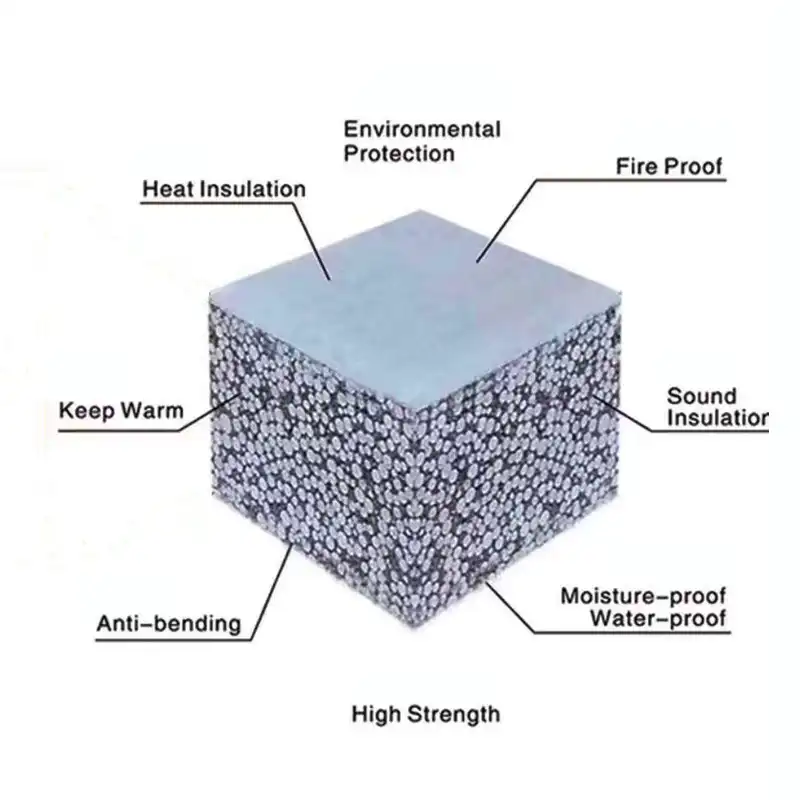

Heat Insulation: EPS cement sandwich panels provide excellent heat insulation, helping to maintain a comfortable indoor temperature and reduce energy consumption for heating or cooling.

Keep Warm: The insulation properties of EPS contribute to keeping the interior spaces warm, especially in colder climates, by preventing heat loss.

Anti-Bending: These panels possess anti-bending properties, making them structurally strong and resistant to deformation or bending under various loads.

Environmental Protection: EPS cement sandwich panels are often considered environmentally friendly as they can be manufactured using recycled materials, and the production process typically has a lower environmental impact compared to some traditional building materials.

Fireproof: The panels are fire-resistant, offering a high level of fire protection and safety in buildings. This property is crucial for preventing the spread of fire and ensuring the safety of occupants.

Sound Insulation: EPS cement sandwich panels provide effective sound insulation, reducing the transmission of noise between different areas or from external sources. This is beneficial for creating quiet and comfortable indoor environments.

Moisture-Proof/Water-Proof: The panels are resistant to moisture and water, preventing issues such as rot, mold, or water damage. This makes them suitable for use in various climates and weather conditions.

High Strength: EPS cement sandwich panels exhibit high strength and durability, making them suitable for use in construction projects where structural integrity is a priority. They can withstand various external forces and loads.

EPS cement sandwich wall panel

Excellent Thermal Insulation: EPS cement sandwich wall panels offer outstanding thermal insulation properties. The Expanded Polystyrene (EPS) core effectively minimizes heat transfer, helping to maintain a comfortable indoor temperature and reduce energy consumption for heating or cooling.

Structural Strength and Anti-Bending Properties: These panels exhibit high structural strength and anti-bending properties, providing a sturdy and durable solution for building construction. The combination of cement-based outer layers and the EPS core contributes to the panels’ ability to withstand various loads without deformation.

Fire Resistance: EPS cement sandwich wall panels are inherently fire-resistant. This feature adds a layer of safety to buildings, as the panels can help prevent the rapid spread of fire and contribute to the overall fire resistance of the structure.

Sound Insulation: The panels offer effective sound insulation, reducing the transmission of noise between different rooms or from external sources. This benefit contributes to creating quieter and more comfortable indoor environments, making them suitable for both residential and commercial applications.

Moisture-Proof and Water-Proof: EPS cement sandwich wall panels are resistant to moisture and water, making them suitable for use in areas prone to humidity or occasional water exposure. This resistance helps prevent issues such as mold growth, rot, and water damage, contributing to the longevity of the building structure.

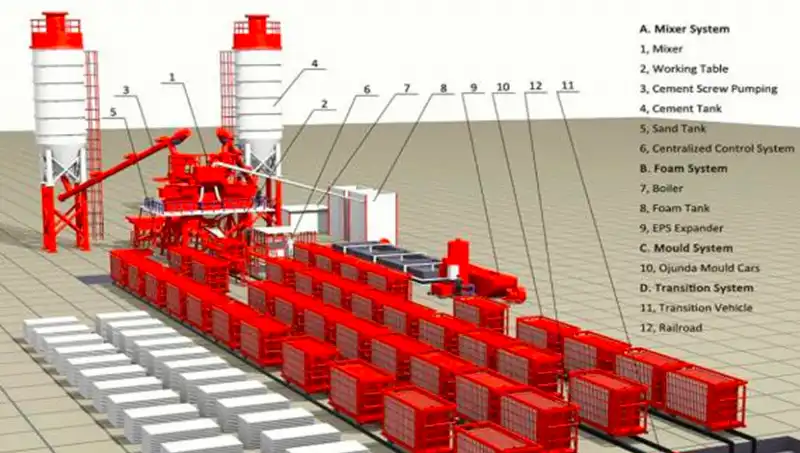

ePS cement sandwich panel production line

The production of EPS (Expanded Polystyrene) cement sandwich panels involves a series of manufacturing processes carried out in a production line. Below is an explanation of the key steps in an EPS cement sandwich panel production line:

Material Preparation: The production line begins with the preparation of raw materials. The main components include cement, sand, water, and additives for the outer layers, and Expanded Polystyrene (EPS) beads for the core. The precise formulation depends on the desired properties of the final panel.

Mixing and Batching: The raw materials are mixed in a specific ratio to create a homogenous mixture. Cement, sand, and additives are combined to form the outer layers, while the EPS beads are mixed with water to create the core material. This mixing process is crucial for achieving the right consistency and properties in the panels.

Panel Molding: The mixed materials are poured into molds of the desired size and shape. These molds determine the dimensions and characteristics of the final EPS cement sandwich panels. The molds are usually made of metal and can be customized based on project requirements.

Curing: After molding, the panels are left to cure. Curing involves a controlled process of drying and hardening the cement-based mixture. This step is essential for achieving the required strength and durability of the panels.

Cutting and Sizing: Once the panels have cured, they are cut to the desired dimensions using cutting machines. This step ensures that the panels meet the specific size requirements of the construction project.

Surface Finishing: The outer surfaces of the panels may undergo additional treatments or finishing processes to enhance their appearance and performance. This can include surface coatings or treatments to improve weather resistance and aesthetics.

Quality Control: Throughout the production line, quality control measures are implemented to ensure that the panels meet the required standards. This may involve regular testing of the raw materials, monitoring the curing process, and conducting inspections of the finished panels for dimensional accuracy and structural integrity.

Packaging and Shipping: Once the panels have passed quality control checks, they are packaged for transportation to construction sites. Proper packaging is essential to prevent damage during transit and ensure that the panels arrive at their destination in optimal condition.

It’s important to note that the specific details of each production line can vary depending on the manufacturer and the intended use of the EPS cement sandwich panels. The efficiency of the production line plays a crucial role in delivering high-quality panels for construction applications.

What are EPS cement sandwich panels?

EPS cement sandwich panels are construction materials consisting of a core layer of Expanded Polystyrene (EPS) foam sandwiched between two layers of cement-based panels. They are commonly used in building construction for their insulation and structural properties.

How are EPS cement sandwich panels manufactured?

The manufacturing process involves mixing cement, sand, and additives to create the outer panels. The EPS core is then inserted, and the entire assembly is cured to form a strong and insulated panel.

What are the key benefits of using EPS cement sandwich panels?

Key benefits include heat insulation, anti-bending properties, environmental friendliness, fire resistance, sound insulation, moisture-proof and water-proof characteristics, and high strength.

Are EPS cement sandwich panels environmentally friendly?

Yes, EPS cement sandwich panels can be considered environmentally friendly. They often use recycled materials in their production, and the manufacturing process tends to have a lower environmental impact compared to some traditional building materials.

How do EPS cement sandwich panels contribute to energy efficiency?

The panels provide excellent heat insulation, helping to regulate indoor temperatures and reduce the need for excessive heating or cooling. This, in turn, contributes to energy efficiency by lowering energy consumption.

Are EPS cement sandwich panels suitable for both residential and commercial construction?

Yes, EPS cement sandwich panels are versatile and can be used in a variety of construction projects, including residential and commercial buildings. They are often used for exterior walls, roofs, and other structural elements.

How do these panels perform in terms of fire resistance?

EPS cement sandwich panels are fireproof and have high resistance to flames. This property helps prevent the spread of fire and ensures the safety of occupants in buildings.

Can EPS cement sandwich panels be customized for specific project requirements?

Yes, manufacturers often provide customization options for EPS cement sandwich panels, allowing them to be tailored to specific project needs in terms of size, thickness, and other specifications.

What is the lifespan of EPS cement sandwich panels?

When properly installed and maintained, EPS cement sandwich panels have a long lifespan. Their durability and resistance to environmental factors contribute to their longevity.

Are EPS cement sandwich panels easy to install?

Yes, EPS cement sandwich panels are relatively easy to install, and their lightweight nature can facilitate faster construction times compared to some traditional building materials.