Features:

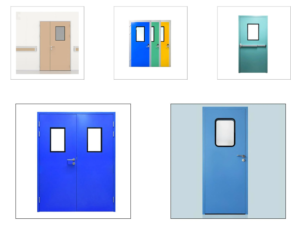

Our high-speed cleanroom doors feature an almost airtight seal, which minimizes pressure drop and protects your environment against drafts, humidity, dust and dirt. Ideal for cleanroom applications in pharmaceutical, chemical, electronics and micro-mechanics industries, our cleanroom doors comply with international standards. Thanks to a break-away system, your personnel and equipment stay safe.

| Door leaf | 1.0 mm galvanized steel plate (honeycomb paper filled) |

| Track rail cover | high-strength aluminum alloy |

| Sensor | infrared safety anti-pinch |

| Gas Tightness | high-strength aluminum alloy all four sides around with sealing joint strip |

| Size | customized per your structural wall openning |

| vision panel | customized , double tempered glass / x-ray proof glass |

| openning | Automatic/Manual(Optional) |

| Hold-close force | >70N |

| Openning speed | 250~500mm/s(adjustable) |

| Closing speed | 250~500mm/s(adjustable) |

| Manual pushing force | <100N |

| lead panel | equivalent is 1-31mmpa |

| CAD drawing | we provide drawing before manufacture doors. |

| No. | Name | Material | Remarks |

| 1 | Door frame and door plank edge covering | 2.0 thick aluminum profile | Surface oxidization |

| 2 | Door plank | Baosteel 0.5 color coated sheet | On the mosaic of stainless steel |

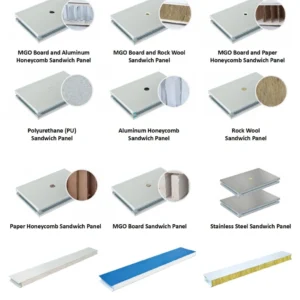

| 3 | Sandwich | Fillings: paper honeycomb, rock wool, aluminum honeycomb | Fire resistance(optional) |

| 4 | Closer | GMT | Grown |

| 5 | Observation window | 5mm double hollow glass of steel | 0.8 inside plate of stainless steel, size: 386×586 arcs |

| 6 | Locks | High-grade handle lock of stainless steel | |

| 7 | Sweeping strip | Sweeping stripof automatic lift | Good elasticity, permanent |

| 8 | Surface treatment | Electrostatic sprat for surface | Never change color, anti-electrostatic spray and optional color |

| 9 | Hinge | Special aluminum alloy hinge | Without external screw |

| 10 | other parts | Hinges of stainless steel, silicone screw | |

| Remarks:the specific size can be customized according to customer’s requirements(up to 2400 mm in height) | |||

1. Pharmaceuticals: Maintains sterile conditions during drug production.

2. Semiconductors: Prevents particle contamination in chip manufacturing.

3. Research Labs: Preserves controlled environments for sensitive experiments.

4. Hospitals: Ensures sterile conditions in operating rooms.

5. Food Production: Guards against microbial intrusion in sterile food manufacturing.

6. Aerospace: Safeguards spacecraft components from contaminants.

7. Precision Instruments: Protects against particles in optical and precision manufacturing.

8. Electronics: Prevents particle and static interference in component assembly.

1.What size are cleanroom doors?

For the double-winged hinged model, the minimum opening dimension is 1300×1800 mm and the maximum is 2400×2500 mm. For single-winged sliding cleanroom doors, the minimum opening dimension is 600×1800 mm and the maximum is 2500×3000 mm.

2.What are the two general types of doors?

Interior doors typically are lightweight and have two hinges; exterior doors are heavy and often use three hinges. Interior doors are usually 1-3/8 inches thick, and exterior doors are commonly 1-3/4 inches thick. A panel door is a classic style. It usually has three or four horizontal rails and three vertical stiles.

3.What type of door is best?

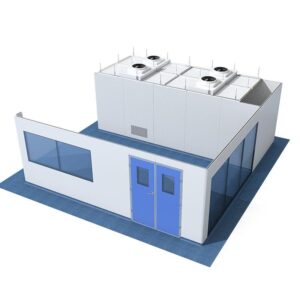

Wise Link’s main products include clean room panels, clean room Aluminum frame/steel frame doors, clean room double glass windows, clean room dynamic pass boxes, FFU, clean room LED light, and so on.