Importing Composite Sandwich Panel From China

Are you looking for the composite sandwich panel with the quality assurance? Here we can supply the most affordable composite sandwich panels to you, and we can support low MOQ. Welcome to contact us now to get more detailed info about composite sandwiched panels.

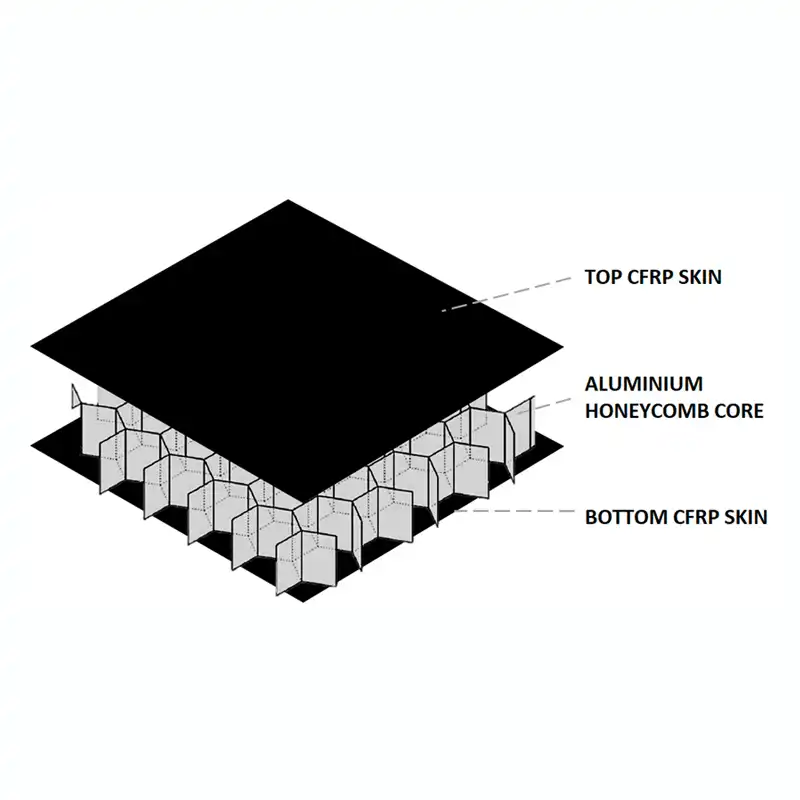

composite sandwich panel structure

A composite sandwich panel structure typically consists of two thin, stiff outer face sheets bonded to and separated by a relatively soft and lightweight core.

The core material, which can be made of various substances such as foams, honeycombs, or wood, enhances the panel’s bending stiffness, while the faces are adhesively bonded to the core to achieve load transfer between the components.

This design provides high bending stiffness with minimal increase in structural mass, resulting in a high stiffness-to-weight ratio. The sandwich panel is commonly used in various applications, including building construction, transportation, and marine industries, due to its enhanced flexural rigidity, fatigue strength, acoustical and thermal insulation, and energy absorption properties

composite sandwich panels

Here we can manufacture all kinds of composite sandwich panels, varied in different thicknesses, lengths, and also different surfaces. You can choose your desired composite sandwiched core panels directly from the sandwich panel manufacturer.

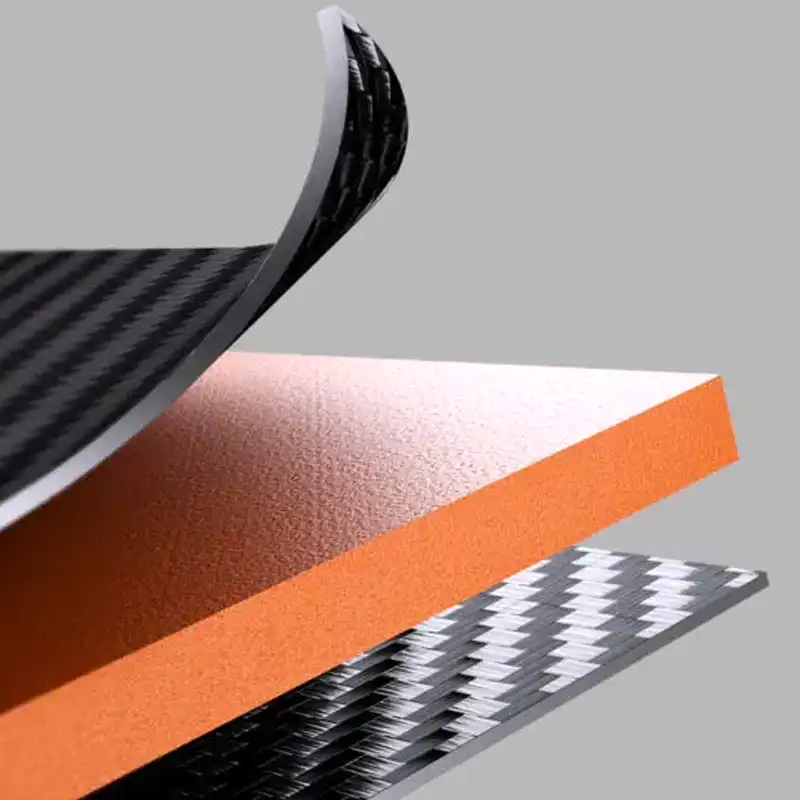

composite foam sandwich panels

Composite foam sandwich panels are a type of composite material that consists of two thin, stiff outer face sheets bonded to and separated by a relatively soft and lightweight foam core. The composite foam sandwich panels have wide applications in the building industries, which are super lightweight, durable.

composite foam sandwich panels eps

Composite foam sandwich panels, particularly those with an Expanded Polystyrene (EPS) core, are a popular construction material due to their lightweight, thermal insulation, and fireproof properties. So get qualified composite sandwich panel EPS from us now.

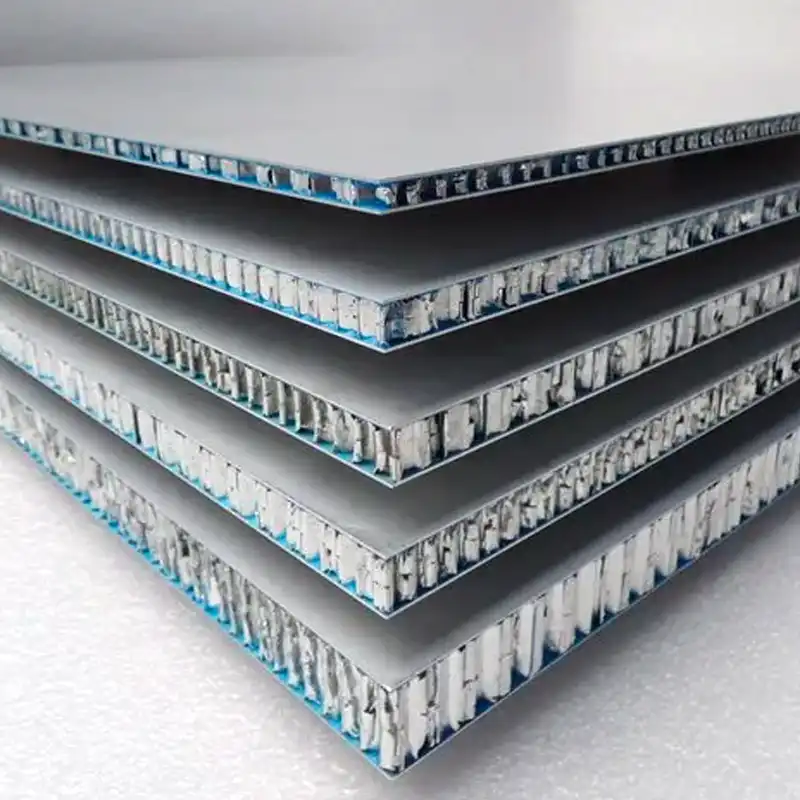

aluminum composite sandwich panel

We also have aluminum composite sandwich panel for your selection to build a prefab house. Aluminum sandwich panels are also lightweight compared with other steel sandwich panels, also offered with the competitive prices. Contact us now to get detailed information about this types of sandwich panels.

what is composite sandwich panel?

A composite sandwich panel is a structural material consisting of two thin, stiff outer face sheets bonded to and separated by a lightweight core. This design aims to provide high bending stiffness while keeping structural mass to a minimum.

What are the key components of a composite sandwich panel?

The main components include two outer face sheets (made of materials like fiberglass, carbon fiber, or aluminum) and a core material (typically foam, honeycomb, or wood).

What is the purpose of the core material in a sandwich panel?

The core material enhances the panel’s bending stiffness without significantly increasing its weight. It acts as a spacer between the face sheets, contributing to the overall strength and rigidity.

How thick can composite sandwich panels be produced?

The thickness of composite sandwich panels can vary based on the specific manufacturer and application. Different manufacturers may offer varying thickness options to suit the needs of different industries and projects

What types of thermoplastic composite sandwich panels are offered?

The types of thermoplastic composite sandwich panels offered can vary based on factors such as recyclability, price, and mechanical properties. Specific offerings may include different thermoplastic materials and configurations to meet various industry requirements

What are the components of a traditional sandwich panel in advanced composites manufacturing?

A traditional sandwich panel in advanced composites manufacturing is comprised of three separate components: fiber, matrix, and core material. This combination of components creates a composite part with exceptional properties different from its individual constituents, resulting in a high-performance final product.

How are the face sheets and core material bonded together?

The face sheets are adhesively bonded to the core material. This bonding is crucial for load transfer between the components and ensuring the structural integrity of the panel.

What industries commonly use composite sandwich panels?

Composite sandwich panels are widely used in building construction, transportation (aerospace, automotive, and rail), and the marine industry due to their high stiffness-to-weight ratio, flexural rigidity, and additional properties like insulation and energy absorption.