Energy Efficiency in Cleanrooms: Reducing Costs Without Compromising Standards in Russia

In the world of cleanroom operations, maintaining a high standard of cleanliness is critical to protecting processes and products, especially in industries like pharmaceuticals, electronics, biotechnology, and food processing. However, the stringent environmental controls in cleanrooms come at a cost—cleanrooms are energy-intensive spaces due to the continuous need for precise control over temperature, humidity, and air quality. Balancing the need for a sterile, controlled environment with cost-effectiveness has led to the growing focus on energy-efficient cleanroom design.

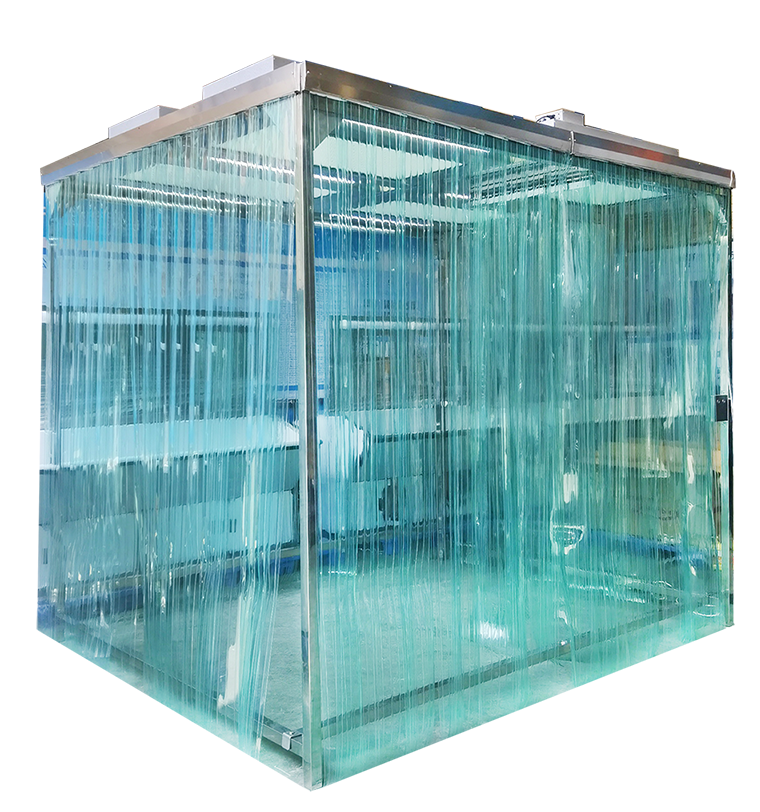

Wise Link, as a leading cleanroom solutions provider, has prioritized energy-efficient cleanroom designs to support clients in reducing operational costs without compromising on quality or compliance. By optimizing HVAC systems, using sustainable materials, and incorporating advanced monitoring technology, we help businesses build and maintain cost-effective cleanrooms that meet industry standards.

In this article, we’ll explore the importance of energy efficiency in cleanroom design, share strategies to reduce costs, and discuss how Wise Link’s approach to cleanroom design ensures compliance and long-term savings.

1. Why Energy Efficiency Matters in Cleanroom Design

Energy efficiency in cleanrooms is critical for two main reasons: cost reduction and environmental sustainability. Cleanrooms can consume up to 50 times more energy per square meter than standard office buildings. High levels of air filtration, heating, cooling, and ventilation demand significant energy usage, and without efficient systems, cleanroom operational costs can quickly escalate.

By prioritizing energy-efficient systems in cleanroom design, companies can achieve:

- Lower Operational Costs: Energy-efficient systems reduce monthly utility bills, saving thousands in annual operational costs.

- Reduced Environmental Impact: Lower energy consumption means a reduced carbon footprint, aligning with global sustainability goals.

- Improved Equipment Lifespan: Efficient equipment operates at optimal capacity, reducing strain and extending the lifespan of critical systems.

Wise Link has incorporated these principles into our design philosophy, ensuring that our cleanroom solutions not only provide the highest standards of cleanliness but also maximize energy efficiency, ultimately supporting both operational and environmental goals for our clients.

2. Strategies for Achieving Energy Efficiency in Cleanrooms

- Advanced HVAC Systems

The HVAC system is the most significant energy-consuming component in a cleanroom, accounting for up to 70% of total energy usage. HVAC systems control air quality, pressure, temperature, and humidity, making them essential for maintaining the cleanroom’s sterile environment. Energy-efficient HVAC systems can drastically reduce energy consumption while maintaining strict environmental standards.

- Optimized Airflow Control: By adjusting airflow rates to the minimum levels necessary for each cleanroom class, HVAC systems can reduce unnecessary energy usage. Using variable air volume (VAV) systems instead of constant air volume (CAV) systems allows the HVAC system to adjust airflow based on the current contamination level.

- Energy Recovery Ventilation (ERV): ERV systems recover energy from exhaust air and use it to precondition incoming air, reducing the energy needed for heating or cooling.

- Efficient Filtration Systems: High-efficiency particulate air (HEPA) and ultra-low particulate air (ULPA) filters are essential for cleanrooms, but they consume significant energy. Choosing high-quality, energy-efficient filters with optimized airflow can reduce energy costs while maintaining filtration standards.

How Wise Link Implements This: At Wise Link, our team assesses each client’s unique needs to design an HVAC system that maximizes airflow efficiency. We utilize modular HVAC systems, which allow adjustments based on operational demands, thus minimizing energy waste while adhering to industry standards.

- Sustainable Materials and Insulation

Using sustainable materials and advanced insulation techniques in cleanroom construction can help reduce energy costs. High-quality insulation limits the need for excessive heating or cooling, making it easier to maintain stable temperatures and humidity levels.

- Insulated Panels: Cleanroom walls and ceilings made from insulated panels, such as PU (polyurethane) or PIR (polyisocyanurate) sandwich panels, provide excellent thermal resistance, reducing the load on HVAC systems.

- Low-Emissivity (Low-E) Coatings: Low-E coatings on cleanroom windows reduce heat transfer, maintaining interior temperature and minimizing HVAC strain.

- Eco-Friendly Flooring and Ceilings: Materials like vinyl or epoxy resin, commonly used in cleanroom floors, offer durability and ease of cleaning while contributing to energy efficiency.

Wise Link’s Approach: Our modular cleanroom panels are built with sustainable insulation materials that offer superior thermal and acoustic insulation. These panels provide the dual benefits of reducing operational costs and supporting eco-friendly practices.

- Efficient Lighting Solutions

Lighting is another essential factor in cleanroom energy efficiency. Cleanrooms typically require high-intensity lighting to ensure visibility for meticulous processes. However, inefficient lighting systems can contribute to excessive energy consumption.

- LED Lighting: LEDs consume up to 75% less energy than traditional incandescent or fluorescent bulbs and have a longer lifespan, reducing both energy costs and maintenance requirements.

- Occupancy Sensors and Automation: Installing occupancy sensors and automated lighting systems ensures that lights are only on when needed, especially in low-traffic areas, reducing unnecessary energy usage.

Wise Link’s Solutions: At Wise Link, we integrate energy-efficient LED lights in our cleanroom designs and offer automated lighting controls that reduce electricity consumption while meeting cleanliness and brightness standards.

- Real-Time Monitoring and Smart Controls

Smart controls and real-time monitoring allow businesses to track cleanroom performance and make adjustments to optimize energy usage. Advanced monitoring systems can detect deviations in temperature, humidity, or particle levels and adjust HVAC systems accordingly, minimizing wasted energy.

- Automated Environmental Controls: Smart HVAC controls adjust airflow, temperature, and humidity based on sensor feedback, ensuring optimal conditions with minimal energy use.

- Predictive Maintenance: By using real-time monitoring, predictive maintenance systems can detect when equipment requires servicing, preventing costly breakdowns and extending equipment life.

Wise Link’s Technology Integration: Wise Link offers smart control solutions for cleanrooms, allowing real-time adjustments to environmental parameters. This not only conserves energy but also ensures that cleanrooms continuously meet compliance standards.

3. How Wise Link’s Energy-Efficient Cleanroom Designs Support Cost-Effectiveness and Compliance

With over 15 years of experience in cleanroom solutions, Wise Link understands that each industry has unique requirements. We collaborate closely with our clients to deliver customized cleanroom designs that are both cost-effective and compliant with industry standards such as ISO 14644 and GMP.

Our Process:

- Consultation and Assessment: We start with a thorough assessment of your cleanroom needs, including energy efficiency goals and compliance requirements.

- Design and Customization: Our design team customizes every aspect of the cleanroom, from HVAC systems to material selection, to ensure durability and cost-effectiveness.

- Modular Solutions: Our modular cleanroom panels, HVAC systems, and lighting solutions are designed for flexibility and scalability, enabling easy upgrades and energy savings.

- Compliance and Quality Assurance: All our cleanrooms adhere to international quality standards and industry-specific regulations, ensuring that your facility operates efficiently while meeting regulatory requirements.

By combining high-quality materials, advanced technology, and a customer-centric approach, Wise Link’s energy-efficient cleanroom solutions offer long-term savings and reliability, making us a trusted partner in achieving a durable and compliant cleanroom environment.

Conclusion: Investing in Energy Efficiency for a Sustainable Future

As industries place a greater emphasis on sustainability and cost control, energy-efficient cleanroom designs have become essential for competitive, compliant, and eco-friendly operations. By focusing on advanced HVAC systems, sustainable materials, efficient lighting, and smart controls, businesses can significantly reduce their energy costs without compromising the stringent standards of cleanroom operations.

At Wise Link, our commitment to energy-efficient, durable, and compliant cleanroom solutions helps clients achieve their operational goals and support environmental initiatives. If you’re looking to build or upgrade a cleanroom with a focus on energy efficiency, contact Wise Link today to explore how our tailored solutions can meet your needs. Together, we can design a cost-effective, future-ready cleanroom that supports both your business and sustainability goals.

Lower Your Cleanroom Costs Without Compromising Quality

Discover how Wise Link’s energy-efficient cleanroom designs can support your business goals. Reach out today for a consultation and take the first step toward a smarter, greener cleanroom.