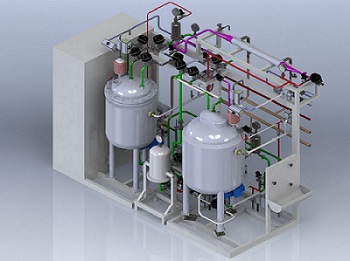

This typical to shows the preparation system introduction:

-

- Automatic preparation system function

-

- Automatic liquid feeding, automatic water replenishment, automatic weighing, automatic stirring, automatic pressure maintenance, automatic liquid transmission, and automatic temperature regulation of the tank are among the several automatic liquid medication preparation controls that can be set up.

-

- Verifiable automatic cleaning system-tank cleaning has no dead ends; according to the verification process, automatic pipeline cleaning, automatic sampling valve cleaning, automatic filter housing cleaning, automatic tank cleaning, and automatic confirmation of the cleaning affect each process.

-

- Automatic SIP control of the preparation system- oonline automatic SIP for various media pipelines and filters.

-

- On-line automatic air tightness detection of the entire liquid preparation system, before the start of each SIP, the liquid preparation system will automatically detect the air tightness online.

-

- On-line automatic test of liquid chemical filter-on-line automatic test after chemical liquid filtration of filter, automatic wetting, and automatic integrity test after online SIP of the filter.

-

- Automatic preparation system advantages

-

- Stable product preparation and production process.

-

- Thoroughness, repeatability, and verifiability of Cleaning and sterilization.

-

- The process parameters such as the cleaning and sterilization records of the system cannot be changed, and the compliance with laws and regulations is better.

-

- Modular design and manufacturing to ensure the design accuracy and production quality of the equipment.

-

- Electrical control is a one-button operation, reducing human intervention.

- Automatic preparation system features

-

- It is designed and fabricated with Customization based on the Pharmaceutical customer process requirements in compliance with ASME-BPE, GMP and related guidelines and rules.

-

- Modular design and fabrications and complete FAT test; high integration of low space occupation ratio with less work contracting surface helps for improving the project execution efficiency and controllable extent.

-

- The critical process parameters for the preparation system are monitored at real online with temperature accuracy PID controlled and high dosing accuracy. It is available to achieve the control function of the material feeding, water feeding, agitating,heating up & cooling down, nitrogen filling, medicine solution transferring to filling automatically, And kinds of production recipes management and function modules of SCADA computer supervision system, intelligence internet-off, intelligence maintenance and remote and fast troubles diagnosis. Electronic signature and record in compliance with the FDA CFR PART11 meeting the computer validation and audit trace requirements.

-

- The preparation system and its piping are hygienically designed without dead legs and blind piping easy to clean and sterilize the whole system with high cleaning efficiency and without colling points during sterilizing.

-

- The sampling system with patent design can achieve cleaning and sterilizing in closed conditions decreasing the contamination during sampling at maximum with a much higher aseptic guarantee and convenient for operation.

-

- It is available for automatic running of CIP/SIP procedure to be validated based on the whole procedure risk control, and the tank and its interconnected piping system are cleaned without dead leg, automatically monitoring the conductivity of drained water, the integrity test is done on line for gas and liquid filter sterilization and post sterilization and the temperature sterilization curve is automatically memorized and printed out.

-

- The system integration function of unpackaging, powder transferring, weighing dosing, and materials feeding are provided for kinds of material crystals and specifications in closed condition as required by the process, effectively evading the negative issues and risks such as personnel cross-contamination, powder dust dispersion, and high labor intensity in compliance with the modernization pharmaceutical process development tendency and high standard requirements relevant with EHS.