Importing Fiberglass Sandwich Panel From China

Are you looking for the top-rated fiberglass sandwich panel from China? Here we are one of the leading fiberglass sandwich panel manufacturers, to provide all-in-one fiberglass sandwich panel solutions for your project, and welcome to contact us at any time to ask for the fiberglass foam sandwich panels.

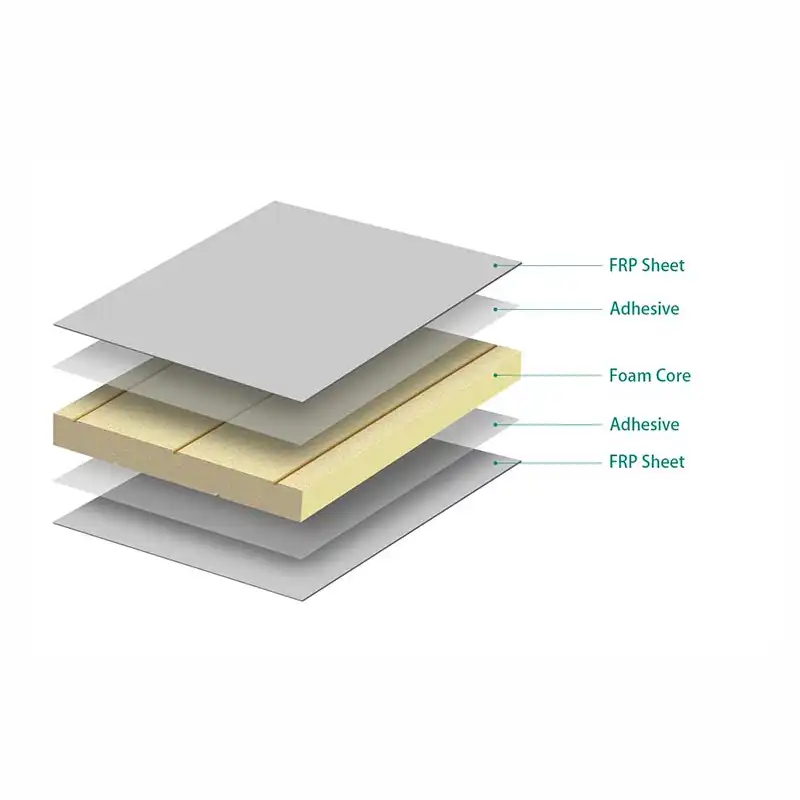

Fiberglass sandwich panel Structure

A Fireglass sandwich panel structure typically consists of three main components:

FRP Sheet (Fiber-Reinforced Plastic): This is the outer layer of the sandwich panel and is made of a composite material that includes strong fibers embedded in a plastic resin. FRP sheets provide durability, strength, and protection.

Adhesive: The adhesive layer is used to bond the FRP sheet to the core material. It plays a crucial role in ensuring a strong and secure connection between the outer layer and the core, enhancing the overall structural integrity of the panel.

Foam Core: The core of the sandwich panel is typically made of foam material. This core provides insulation and contributes to the panel’s lightweight properties. The foam core also adds structural support to the panel.

fiberglass foam sandwich panel price

In our sandwich panel manufacturer, we can work out the best sandwich panel solutions for your construction project, from the sandwich panel manufacturing to the packaging, we can focus on details to achieve the qualified sandwich panels before loading on the container. Welcome to contact us at any time if you are looking for the reliable sandwich panels factory in China.

fiberglass sandwich panel Advantages

A Fireglass sandwich panel structure typically consists of three main components:

FRP Sheet (Fiber-Reinforced Plastic): This is the outer layer of the sandwich panel and is made of a composite material that includes strong fibers embedded in a plastic resin. FRP sheets provide durability, strength, and protection.

Adhesive: The adhesive layer is used to bond the FRP sheet to the core material. It plays a crucial role in ensuring a strong and secure connection between the outer layer and the core, enhancing the overall structural integrity of the panel.

Foam Core: The core of the sandwich panel is typically made of foam material. This core provides insulation and contributes to the panel’s lightweight properties. The foam core also adds structural support to the panel.

What is a Fiberglass Sandwich Panel?

A Fiberglass sandwich panel is a composite material consisting of layers of fiberglass reinforced plastic (FRP) sheets on both sides of a core material. The core is often made of foam and provides insulation and structural support.

What are the Advantages of Fiberglass Sandwich Panels?

Fiberglass sandwich panels offer a combination of strength, durability, and insulation. They are lightweight, resistant to corrosion, and have excellent thermal and electrical insulating properties.

Where are Fiberglass Sandwich Panels Used?

These panels find applications in various industries, including construction, transportation (such as in RVs and boats), aerospace, and industrial settings. They are commonly used for walls, ceilings, floors, and other structural elements.

How is the Installation Process for Fiberglass Sandwich Panels?

Installation involves securing the panels to a structural framework using appropriate adhesives or mechanical fasteners. The exact process can vary depending on the specific application and project requirements.

Are Fiberglass Sandwich Panels Environmentally Friendly?

Fiberglass itself is a recyclable material. However, the environmental impact depends on the specific manufacturing processes and the disposal/recycling practices employed. Some manufacturers prioritize eco-friendly practices in their production.

Can Fiberglass Sandwich Panels be Painted or Coated?

Yes, fiberglass sandwich panels can be customized in terms of size, thickness, and surface finishes. They can also be tailored to meet specific performance requirements, making them versatile for different applications.

Can Fiberglass Sandwich Panels be Customized?

Yes, fiberglass sandwich panels can be painted or coated to achieve specific aesthetics or enhance protective properties. It’s important to use coatings compatible with the panel materials to ensure adhesion and durability.