Mineral wool Sandwich plate application range is very wide

A cold room or freezer;

Vegetable and fruit storage room;

Logistics facilities, cold storage;

Production and office buildings, workshops;

Service station, hangar.

Any fiber material created by spinning or pulling molten rock or mineral materials, such as slag and ceramics, is referred to as mineral wool.

Mineral wool finds its application in soundproofing, filtration, hydroponic growing medium, and thermal insulation (as pipe and structural insulation).

|

Compressive strength

|

85kpa

|

|||

|

Shear strength

|

60kpa

|

|||

|

Tensile strength

|

170kpa

|

|||

|

Slag ball content

|

<5 (size of coarse slag ball>0.25mm)

<30 ( size of coarse slag ball>63μm)

|

|||

|

Thermal conductivity of rock wool panel

|

0.038(average temperature 20ºC)

|

|||

|

Fireproof rating

|

Noninflammable material

|

|||

|

Reaction to fire

|

Grade A

|

|||

|

Fire-resistant limit(FRL)

|

According to the structure and thickness of sandwich panel,FRL is between 30mins and 240mins.

|

|||

|

Hydroscopicity

|

<1

|

|||

|

Hydrophobicity(specific to hydroph-obic products)

|

>=98

|

|||

|

Aging and expansion rate

|

<=5(thickness change rate after 24 hours under the state of 65ºC)

|

|||

|

Melting temperature

|

>1000ºC

|

|||

|

Fiber diameter

|

<=7μm

|

|||

| Thickness | 50/75/100/120/150/200(mm) |

| Effective width | 950, 980, 1100, 1150(mm) |

| Length | According to customer’ s request, less than 11.8m. |

| Materials | Polystyrene foam board, Color steel sheet |

| Structure | Upper and lower layer: 0.4mm-0.8mm Color steel sheet |

| Middle: Polystyrene foam board | |

| EPS density | 60/80/100/120 kg/m³ |

| Conventional color | White, sea blue, red etc. |

| Lifetime | More than 60 years |

| Performance | Light weight, heat insulation, water resistant, green and environmental |

| Usage | Roof, Wall, Ceiling, Partition |

| Aspects | Advantages |

| Fire rating | * A non-combustible |

| Sound insulation | * Sound insulation noise reduction |

| Color | * Any color (usually blue) |

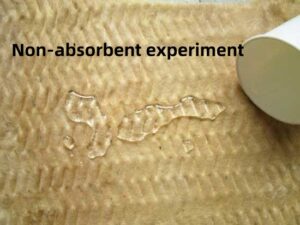

| Water proof | * Non-absorbent and anti-aging |

| Environment | * Biodegradable and environmental friendly |

| Acidity coefficient | * 1.4 ; Reduce corrosion of metals |

| Differences with mineral cotton | * Mineral cotton’s acidity coefficient is 1.1 lower than rock wool, calcium oxide and magnesium oxide are higher than rock wool that has strong corrosion of metals. This is why rock wool is better than mineral cotton. |

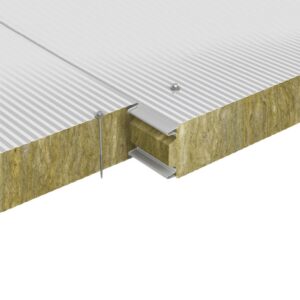

| Strength | * We will cut the whole piece of rock wool into same length, thick, and width rock wool stripes . Turn them over for 90º to make the rock wool silk stand instead of flat . It increases the strength more . We also break the orderly arrangement of rock and stagger them in the same length. It may perfectly have more strength than ordinary rock wool sandwich panels. |

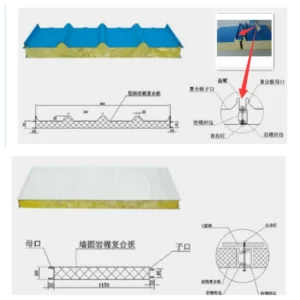

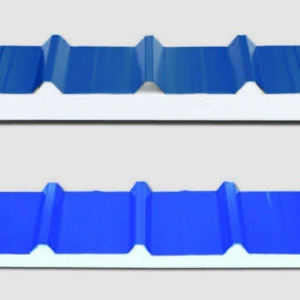

| Roof wave crest data | * Height : 42 mm. Space distance between two wave crest: 333 mm. |

| Effective width | * 1000 mm |

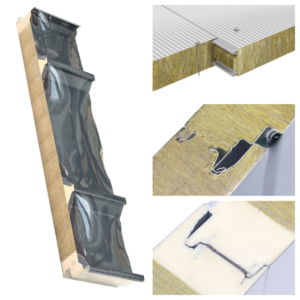

| Special design of each side | * Polyurethane are used in both sides in order to increase the insulation performance of rock wool sandwich panels. It improves air impermeabi lity and water tightness between the two joint pieces. It avoids cold bridge phenomenon . Furthermore It overcomes the occurrence of stripping of steel plate and core material at the junction of plate in the process of handling and installation. So it is our new type rock wool sandwich panel and it avoids the disadvantage of poor air tightness of traditional rock wool sandwich board. |

| Surface appearance sorts | * Flat -F ; Square wave -S ; Water ripple-W; Concave in water ripple-WC; Big wave -BW; All around tongue-and-groove curtain wallboard–TG; Ripplet–V8. All kinds of surfaces for your choosing. |

1. Fire Prevention: Class A fire-proof performance and premium water-proof rock wool.

2. Thermal Insulation: The sealing performance and the thermal insulation effect are ensured by the good node design and the low coefficient of heat conductivity.

3. Sound Insulation: There is a good amount of sound absorption. There is a minimum of 30dB sound reduction factor. It has the ability to successfully lessen outside noise disturbance.

4. Solid: The panel may be utilized for both load-bearing and externally protected construction due to its great strength, special double-support plug interface design, and excellent capacity in wind pressure resistance.

5. Beautiful Design: The design is eye-catching and visually appealing, requiring no additional outside ornamentation. The panel features a variety of panel effects and a hidden-screw node architecture.

6. Easy Installation: Quick, adaptable, and simple. It can shorten the construction time by more than 40% as compared to civil construction.

1.What is mineral wool made of?

Rock, blast furnace slag, and other raw materials are melted and spun into fibers to simulate the texture of wool to create mineral wool insulation, also known as rock or slag wool insulation. Mineral wool is available in rolls, batts, and loose-fill shapes.

2.Is mineral wool the same as ROCKWOOL?

Mineral wool, also known as ROCKWOOL or stone wool, is made from a selection of raw materials, such as stone and glass.

3.Are there any health risks when using mineral wool?

Acute (short-term) effects of fine mineral fibers in humans consisted of upper respiratory tract irritation, with symptoms such as coughing, sore throat, and nasal itching and congestion; however, these symptoms did not continue after exposure ceased.

4.Can mineral wool get wet?

The short answer is yes, mineral wool can get wet. However, it has a unique property that sets it apart from other insulations – it can retain its insulating performance even when damp. Here’s why: Mineral wool fibers are hydrophobic, meaning they repel water.

You may also want to know :

Q1: Do you offer guiding service for installation on site overseas?

A: Yes. We do. We will give detailed installation drawings and video for free. And if you need, we can send guide engineers as installation director even a working team to your construction site.

Q2: How can I get your quick quotation on my project?

A: You can chat with us at anytime via email or phone to offer us your detail information or you can just leave your message on our website. We will give you the best quotation ASAP.

Q3: What’s the procedure of trading?

A: Design drawing →Confirm drawing→Quotation→PI→ConfirmPI→Arrange 30% deposit→Manufacture→ QCinspect→ Paybalance→Shipping.

Q4: What is the biggest advantage of your product?

A: We use high-quality raw materials, strictly control the quality of production. We improve our product performance by improving our technology. These make our products more beautiful and have a longer life, lower cost of use.

Wise Link’s main products include clean room panels, clean room Aluminum frame/steel frame doors, clean room double glass windows, clean room dynamic pass boxes, FFU, clean room LED light, and so on.