Panel facings are made of galvanized steel sheet, coated with polyester paint, thickness from 0,4 to 0,6 [mm] as options. The steel we use to produce our panels are delivered by biggest world steel concerns.

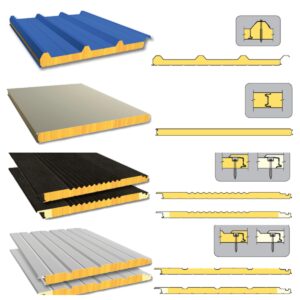

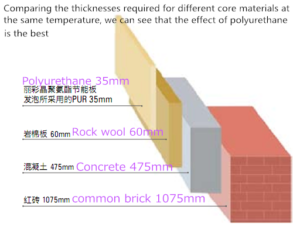

The core of the panel can be made of polyurethane foam (PUR) or (PIR) with density of 40 kg/m3, mineral wool with density of 100 kg/m3 or 85 kg/m3 (LITE) or expanded polystyrene (EPS) produced by our own factory.

Polyurethane composite panels are also called PU sandwich panels.

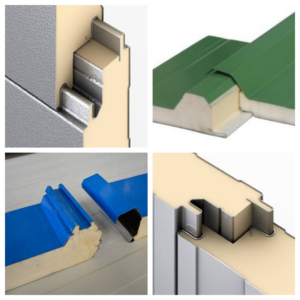

The composite panel with polyurethane as the core material is composed of the upper and lower layers of color steel plate and the intermediate foamed polyurethane, which adopts the world’s most advanced six-component online automatic operation mixing and pouring technology, which can complete the proportioning and mixing process of the social batching center or factory online at one time, and can be adjusted at will according to the temperature online, so as to produce a unique high-strength, energy-saving, green and environmentally friendly building panel.

Polyurethane sandwich panels are widely used in large industrial plants, cold storage, garages, mobile homes, exhibition halls, exhibition halls, gymnasiums, shopping centers, airports, power plants, villas, hospitals, strata and high-rise office buildings and other fields.

It is generally used for the roof outer layer board of the building, which has good thermal insulation, heat insulation and sound insulation effects, and polyurethane does not support combustion, in line with fire safety. The joint action of the upper and lower plates and polyurethane has high strength and rigidity, and the lower plate is smooth and flat, with clear lines, which increases the interior aesthetics and flatness. It is easy to install, short in construction period and beautiful, and is a new type of building material.

The sandwich panel has light weight, beautiful and good anti-corrosion performance, and can be directly processed, it provides a new type of raw material for the construction industry, shipbuilding industry, vehicle manufacturing industry, furniture industry, electrical industry, etc., and has played a good effect of replacing wood with steel, efficient construction, energy saving, and pollution prevention.

| Type | Metal sandwich panels |

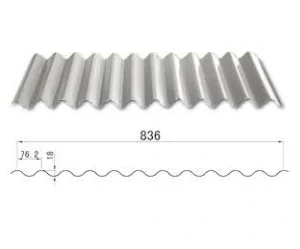

| Surface | 0.4-0.8mm PPGI OR PPGL(Color coated steel) for two faces |

| Core material | EPS,Rock Wool,PU/PIR,Glass wool or special core materials for clean panels(paper honeycomb,AL honeycomb and so on) |

| Thickness of core | 40,50,75,100,150,200,300(mm) |

| Width | 930,950,980,1000,1030,1130,1150,1180mm |

| Length | Customised(max 11.8m, acoording to the container size) |

| Application | Outside roofing,wall,partition wall panels,cleanroom,coldroom,warehouse,workshop,School, Museum,Shopping mall,4S Car store and so on. |

| Features | Light weight,Economical, green and environmentally friendly |

| Advantaged | Fireproof,Insulated,Quickly installation |

| Equipment | Advanced PUMA and other production line with Accurate accuracy |

| Certificate | ISO 9001,ISO14001,CE,FM |

| Properties of panels | Polyurethane panel | Polyisocyanurate panel | Mineral wool panel | EPS Foam |

| Core Density | 40kg | 40kg | 80-120kg | 8-20kg |

| Insulation core Thermal value |

0.023(W/mk) | 0.023(W/mk) | 0.045(W/mk) | |

| Fire Resistance grade (EN13501-1) | C-S2,D0,15min | B-S2,D0,45min | A2-S1,D0,100-120min | |

| Sound absorption | 25dB | 25dB | 34dB | 22dB |

| PUR/PIR Sandwich Panel Technology Data | |

| Density | 40-43kg/m3 |

| Thermal conductivity | 0.019-0.023W/M.K |

| Moisture permeability coefficient | ≤3.34Ng/Pa/m.s |

| Water absorption | ≤0.5g/100cm2 |

| Enclosed rate | ≥97% |

| The compression strength | ≥220KPa |

| The bending strength | ≥2450KN/m2 |

| Oxygen index | ≥28 |

| Fire proof | B1 |

| Dimensional stability | ≤1% |

| Application temperature | -50ºC-150ºC |

| Exterior Steel thickness | 0.35-0.8mm |

| Interior steel thickness | 0.35-0.8mm |

| Core material thickness | 40/50/60/75/80/100/120/150/200mm |

| Length | Less than 11.8m |

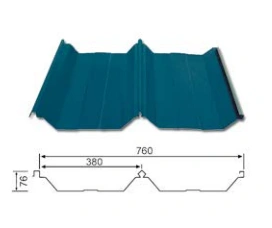

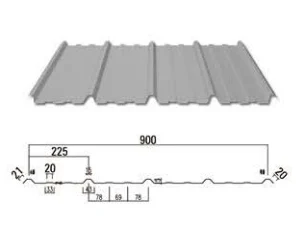

| Effective width | Wall panel:400-1120mm;Roof panel:1000mm |

| Grace finish | Embossment,small wave,big rib,flat finish,Lowribs |

| USAGE | Roof and Wall |

| Advantage | Heat Insulation, light weight, quick installation,waterproof, fireproof, soundproof, energy-saving,environmental friendly, |

Company information:

Qingdao Wise link International, which has been with the building industry for more than 15 years, is a top building material manufacturer and trading supplier. We focus on developing the international market and international business.

Qingdao wise link international supplies the building materials, such as Polyurethane sandwich panels, EPS/Rockwool sandwich panels, PPGI steel coils, steel structure buildings, prefab houses, Modular houses, Cleanroom sandwich panels, cleanroom doors, cleanroom windows, and lab facilities, we supply one-stop service from designing, manufacturing, supplying, and installation for the overseas project.

We export building materials to Southeast Asia, Africa, America, Europe, and Middle Eastern countries, because of our trustable quality and service, all clients give a good reputation, and we will keep the highest level of service for all clients.

Welcome, contact us!

You may also want to know :

1.What is PIR sandwich panels?

Polyisocyanurate or PIR is a fireproof insulation material, derived from polyurethane. The PIR sandwich panels are manufactured on the continuous lines and the space between the metal sheets is filled with fireproof polyisocyanurate foam.

2.What is the difference between PIR and EPS panels?

PIR panels are made from polyisocyanurate foam, which is a higher density foam than EPS. PIR foam has better thermal insulation properties than EPS, making it ideal for use in more demanding applications such as commercial buildings, warehouses, and other industrial settings.

3.What are the advantages of PIR?

➨Detects motion reliably in indoors as well as in day or dark.

➨It consumes less energy (0.8W to 1.0W) compare to microwave sensor.

➨They are cheaper compare to microwave sensors.

➨They are good for electrical applications used in smaller and compact premises.

Wise Link’s main products include clean room panels, clean room Aluminum frame/steel frame doors, clean room double glass windows, clean room dynamic pass boxes, FFU, clean room LED light, and so on.