HEPA vs. ULPA Filters: Choosing the Best Filtration System for Your Cleanroom

Written by Wiselink Group, Qingdao, China

When it comes to maintaining a sterile environment in a cleanroom, filtration systems are essential in ensuring that airborne contaminants are minimized or eliminated. Cleanrooms are crucial spaces for various industries, including pharmaceuticals, biotechnology, electronics, and medical device manufacturing, where even the smallest particle can have a significant impact on product quality and safety. In these environments, HEPA (High-Efficiency Particulate Air) filters and ULPA (Ultra-Low Penetration Air) filters are the two primary types of filters used. While both offer excellent filtration capabilities, they have distinct differences that make them suitable for different cleanroom applications.

At Wiselink Group, we specialize in providing top-tier filtration solutions designed to meet the specific needs of cleanroom environments. In this blog, we will delve into the differences between HEPA and ULPA filters, their respective advantages, and how to choose the best filtration system for your cleanroom.

Understanding HEPA Filters

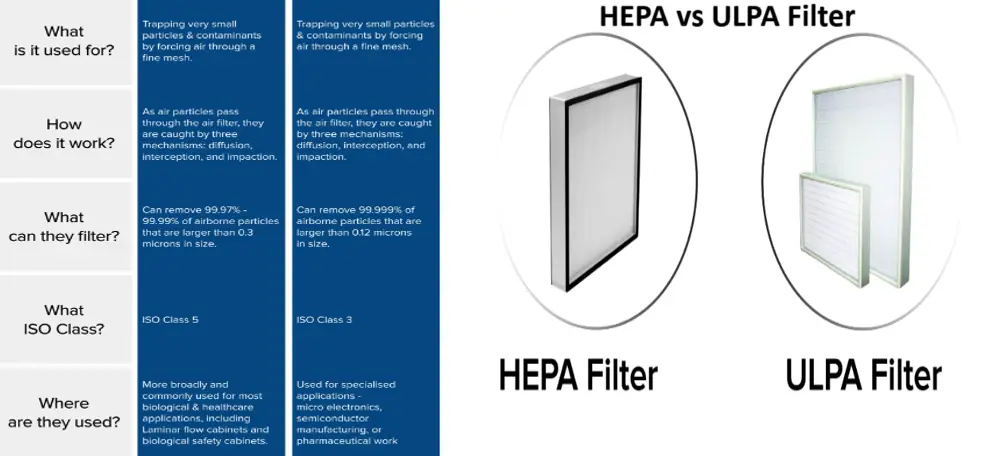

HEPA filters are one of the most commonly used filtration systems in cleanrooms. These filters are designed to capture at least 99.97% of particles that are 0.3 microns or larger in diameter. This includes a wide range of particulate contaminants such as dust, pollen, mold spores, bacteria, and other pollutants. HEPA filters are primarily used in cleanrooms that require high levels of contamination control but not to the most stringent standards.

HEPA filters operate by forcing air through a dense filter material that traps contaminants. The filter’s media, often made from fiberglass, is woven in a way that creates tiny pores that can capture particles as air passes through. The efficiency of HEPA filters is measured based on their ability to trap particles of a specific size, particularly those that are 0.3 microns in diameter, which is known as the most penetrating particle size (MPPS). Although they are highly effective, HEPA filters are limited by their filtration efficiency for particles that are smaller than 0.3 microns.

Key Benefits of HEPA Filters:

- Widely used and cost-effective: Due to their affordability and availability, HEPA filters are the go-to choice for many cleanroom applications.

- High filtration efficiency: Captures up to 99.97% of particles that are 0.3 microns or larger.

- Easy to maintain: Regular filter replacement and maintenance are required but are relatively straightforward.

Applications of HEPA Filters:

- Pharmaceuticals (Class 100 and Class 10 cleanrooms)

- Electronics manufacturing

- Medical device assembly

- Biotechnology research

What Are ULPA Filters?

ULPA filters are a more advanced filtration system compared to HEPA filters. These filters are designed to capture at least 99.9995% of particles that are 0.12 microns or larger. ULPA filters are most commonly used in cleanrooms that require the highest levels of cleanliness, such as those in the semiconductor industry, certain pharmaceutical applications, and research labs.

ULPA filters work similarly to HEPA filters but with a higher level of filtration efficiency. These filters are typically made from fine fiberglass and use a dense mesh of fibers to trap particles. The key difference between HEPA and ULPA filters is that ULPA filters have smaller pore sizes, which allows them to capture particles as small as 0.12 microns, making them highly effective for environments where the tiniest contaminants can have a significant impact.

Key Benefits of ULPA Filters:

- Superior filtration: Capable of capturing up to 99.9995% of particles 0.12 microns or larger, ULPA filters offer a higher level of air cleanliness.

- Ideal for highly sensitive environments: These filters are perfect for industries that require strict contamination control.

- Efficient for smaller particles: Unlike HEPA filters, ULPA filters can capture particles that are smaller than 0.3 microns, which is critical for highly sensitive applications.

Applications of ULPA Filters:

- Semiconductor manufacturing

- Advanced pharmaceutical production (Class 100 cleanrooms)

- Aerospace and medical device manufacturing

- High-end research facilities

Key Differences Between HEPA and ULPA Filters

The main difference between HEPA and ULPA filters lies in their efficiency at capturing different sizes of particles. While both filters can effectively remove contaminants from the air, the distinction comes down to the level of cleanliness required in the cleanroom.

Filtration Efficiency:

HEPA filters capture 99.97% of particles that are 0.3 microns or larger, whereas ULPA filters capture 99.9995% of particles that are 0.12 microns or larger. This makes ULPA filters ideal for environments that require ultra-clean air.Particle Size:

HEPA filters are most effective at capturing particles around 0.3 microns in size, but ULPA filters are capable of trapping smaller particles down to 0.12 microns. This makes ULPA filters essential for cleanrooms that deal with extremely fine particulate matter.Cost and Availability:

HEPA filters are generally more affordable and easier to source compared to ULPA filters. ULPA filters tend to be more expensive due to their higher level of filtration efficiency and more complex manufacturing process.Applications:

HEPA filters are suitable for most cleanroom environments, such as pharmaceutical production and medical device manufacturing. ULPA filters are required for more stringent environments, such as semiconductor manufacturing or high-tech aerospace applications.

Choosing the Right Filtration System for Your Cleanroom

Selecting the appropriate filtration system for your cleanroom is crucial to maintaining the desired environmental conditions. The decision between HEPA and ULPA filters depends on several factors, including the cleanliness level required, the size of the cleanroom, the type of contaminants present, and the specific industry regulations you need to adhere to.

When choosing a filtration system, consider the following:

Cleanroom Class: The classification of your cleanroom (e.g., ISO Class 5, Class 7) will determine the level of filtration required. For higher-class cleanrooms, ULPA filters may be necessary to maintain the stringent cleanliness standards.

Type of Work: If your cleanroom is used for semiconductor manufacturing or other high-tech industries, ULPA filters will be the best choice to ensure the air is free from microscopic contaminants. For less sensitive industries, HEPA filters will provide sufficient air quality.

Regulatory Compliance: Depending on the industry, you may need to comply with specific regulatory standards. Be sure to choose filters that meet the requirements for your cleanroom, such as ISO 14644 or cGMP (current Good Manufacturing Practices) standards.

Cost Considerations: While ULPA filters offer superior filtration, they are more expensive. If budget constraints are a concern, HEPA filters may offer a cost-effective solution while still providing excellent performance.

Why Choose Wiselink Group for HEPA and ULPA Filters?

At Wiselink Group, we are committed to providing the highest-quality cleanroom solutions, including HEPA and ULPA filters that meet the specific needs of your industry. Our filters are designed to offer maximum efficiency and reliability, ensuring that your cleanroom maintains the highest standards of air quality.

Here are some reasons why you should choose Wiselink Group for your cleanroom filtration needs:

Premium Quality: We use only the highest-grade materials to manufacture our HEPA and ULPA filters, ensuring superior performance and longevity.

Tailored Solutions: We offer customized filtration systems to meet the unique needs of your cleanroom, whether it’s for pharmaceutical production, semiconductor manufacturing, or research labs.

Expertise and Experience: With years of experience in cleanroom solutions, our team of experts can guide you through the process of selecting and installing the right filtration system for your facility.

Global Reach: Wiselink Group has established a strong presence in cleanroom solutions worldwide. Whether you are in Asia, Europe, or North America, we can supply and install HEPA and ULPA filters that meet your specific requirements.

Comprehensive Support: We offer full maintenance and support services to ensure your filtration system operates optimally, maintaining the cleanliness of your cleanroom over time.

.

Optimize Your Cleanroom Filtration with Wiselink Group

If you’re looking for high-quality HEPA and ULPA filters to optimize your cleanroom’s air quality, Wiselink Group is the partner you can trust. Our state-of-the-art filters are designed to meet the most stringent cleanroom requirements and ensure maximum efficiency. Contact us today to learn more about our filtration systems and how we can help you create a contamination-free environment.