Main Products

-

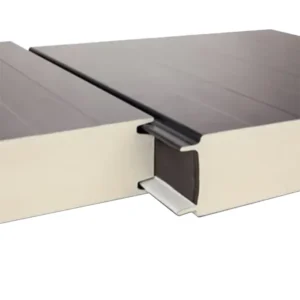

50mm PPGI Rockwool Sandwich Wall Panel Modular Cleanroom for Food Workshop with CE

Read more -

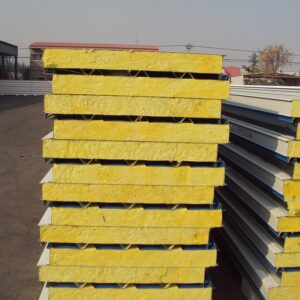

Steel Structure used Glass Wool Sandwich Panel For outside cladding system

Read more -

Prefabricated Metal Construction Building Materials EPS Sandwich Wall Panel for Sale

Read more -

Steel Building Glass Wool Sandwich Wall Panel

Read more -

Clean Room Pass Box Without Interlock

Read more -

Cold Room Panel

Read more -

Clean Room Sandwich Panels

Read more -

Cleanroom Window

Read more -

Metal Steel Airtight Sliding Cleanroom Medical Laboratory Hermetic Operating Clean Room Automatic Hospital Doors for Hospital

Read more

PRODUCTS & TECHNOLOGY

Focus On Cleanroom Engineering Solutions

The success of your business, your reputation, and the caliber of your products all hinge upon the cleanliness and efficiency of your cleanroom.

Ensuring an environmentally controlled facility is crucial for smooth production, operational flow, and timely product delivery. This necessitates the expertise of a top-tier professional who can guarantee that your facilities not only meet but surpass every industry standard.

At Wise Link, we stand at the forefront of cleanroom design, engineering, and construction. With our extensive experience, we are dedicated to delivering unparalleled solutions to our clients each and every day.

Why Choose Us

Custom Design

- Always be responsible and reliable

- Expert engineering support and process analysis

- One-stop solution for customized products

- Fast prototype, Flexible MOQ, Custom packaging, On- time delivery

Quality Assurance

- GMP/WHO-compliant

Cleanroom Codes and Regulation-compliant. - Control and Monitor: Keep processes in check, and track air quality, temperature, and more for consistency.

- Manage Risks: Identity, mitigate and handle potential issues effectively.

- Keep Improving: Continuously enhance by analyzing data, spotting opportunities, and refining processes.

Services

- A professional engineering team to offer some assistance for 3D design, process plan, and cost evaluation

- A pair of eyes all through projects going on. We can be the extension of the customer’s team on the manufacturing site, trying to provide information as detailed as it can be.

- A strategic partner of your business with smooth communications

How We Work

New Project RFQ

Customers need to provide a detailed drawing for the parts that need to be customized, including material, tolerance, surface and quantity.

Each RFQ will be in a deep and detailed study by our experienced team. We will suggest processes and facilities that are best suited for the product you need.

When required, your quality and manufacturing questions are reviewed between you and our quality engineer prior to finalizing the quote.

Prototype Before Run Production

Always make new tooling and provide samples for your inspection and approval.

In addition, before the real production, we will use the simulation pouring technology to test the rationality of the process design, especially for some thin-walled parts and complex structural parts, and we can also provide 3D printing technology for some products that are not suitable for mold making in a small batch.

In a word, we will provide qualified samples and our test reports for your further inspection by DHL, FedEx or UPS.

Quality Inspection

Quality inspection is crucial in the Cleanroom manufacturing process, encompassing checks on raw materials, process steps, and final products to ensure they adhere to standards and specifications.

Quality inspection often involves the use of advanced testing equipment and techniques to ensure product accuracy, reliability, and performance. This may entail testing and validating aspects such as dimensions, appearance, functionality, chemical composition, and more.

Ensuring that products meet customer expectations and comply with relevant industry standards and regulations. This is particularly crucial in fields such as pharmaceuticals, semiconductors, biotechnology, where products are highly sensitive to environmental contamination and quality issues.

Blogs

Advantages of Anti-Microbial Wall and Ceiling Panels in Cleanroom Construction

Advantages of Anti-Microbial Wall and Ceiling Panels in Cleanroom Construction Written by QINGDAO WISE LINK – WISE LINK GROUP In industries where sterility and hygiene

Why Fire-Rated Cleanroom Wall Panels are Critical for Pharmaceutical Facilities

Why Fire-Rated Cleanroom Wall Panels are Critical for Pharmaceutical Facilities Written by QINGDAO WISE LINK – WISE LINK GROUP In pharmaceutical facilities, safety and compliance

Chemical-Resistant Materials for Eye Drop Production Facilities: A Guide

Chemical-Resistant Materials for Eye Drop Production Facilities: A Guide Written by QINGDAO WISE LINK – WISE LINK GROUP In eye drop production facilities, maintaining sterility,

Are you looking for something else?

You can’t find what you are looking for?

- info@wiselinkgroup.com

- 0086 135 0543 8173

- Contact us via WhatsApp