How Cleanrooms are Integral to the Aerospace Industry

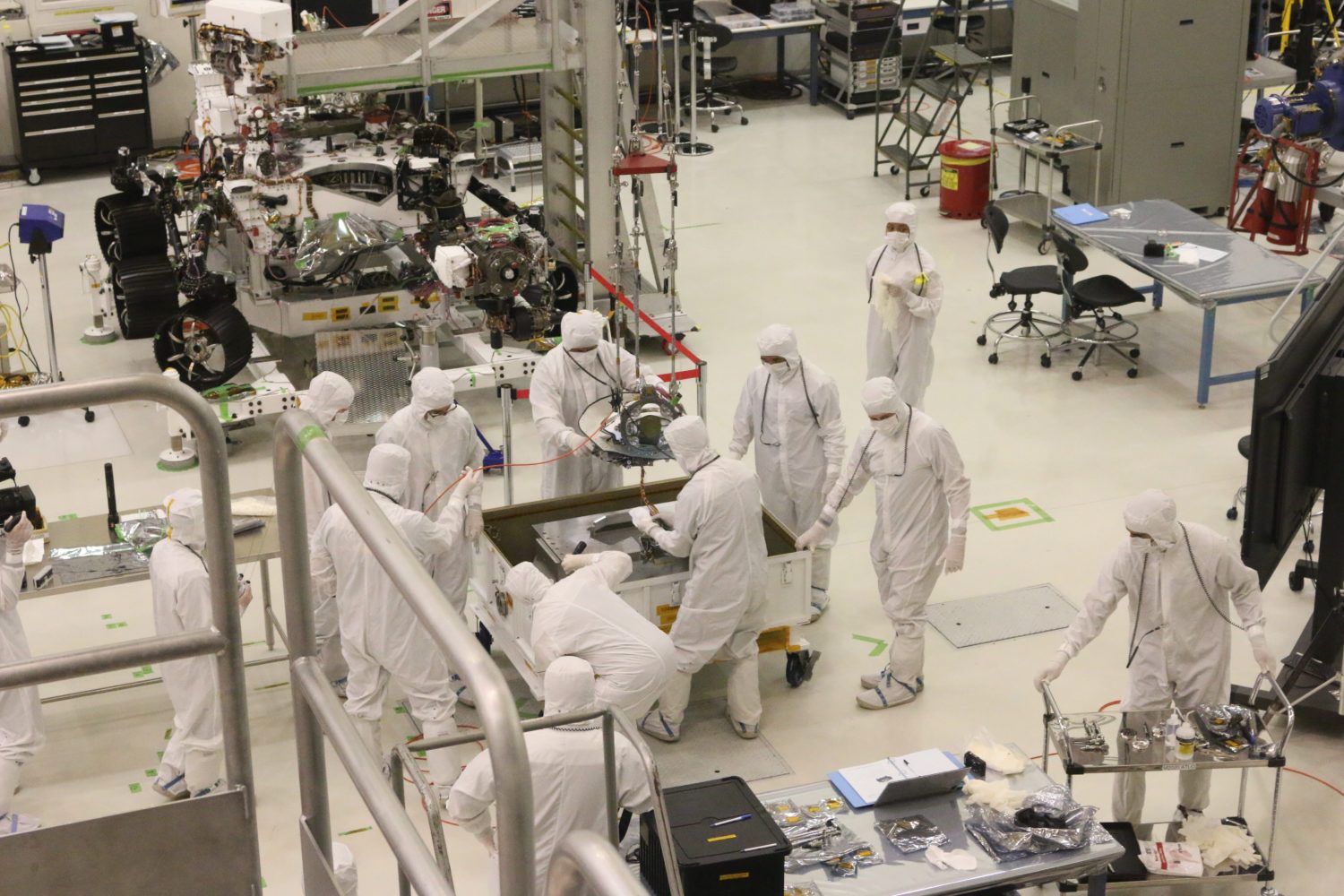

The aerospace industry is one of the most demanding sectors, where precision, reliability, and safety are non-negotiable. Every component, whether for a commercial aircraft or a spacecraft, needs to be manufactured in a controlled environment to ensure it meets the highest standards of quality and performance. Cleanrooms have become integral to this process, offering a sterile and highly controlled environment for the design, assembly, and testing of aerospace components.

In this blog, we will explore how cleanrooms play a crucial role in the aerospace industry and why meeting aerospace cleanroom requirements is essential for the success of aerospace manufacturing and technology. We will discuss the importance of cleanroom standards, the specific aerospace cleanroom requirements, and how Wiselink Group ensures that its cleanroom solutions meet the stringent demands of the aerospace sector.

Why Cleanrooms are Vital for the Aerospace Industry

The aerospace industry encompasses the design, production, and testing of a wide range of components, including satellites, propulsion systems, aircraft parts, and space exploration equipment. Each of these components must meet strict quality controls, as even the smallest contaminant can compromise the integrity and functionality of the equipment.

Cleanroom Environment for Aerospace Manufacturing

- Precision Engineering: Aerospace components often require extremely fine tolerances. Cleanrooms offer the controlled environment necessary to produce components with minimal risk of contamination.

- Contamination Control: Even tiny particles, such as dust or oils, can interfere with the performance of sensitive aerospace components. Cleanrooms are designed to prevent contamination, ensuring that particles do not settle on critical parts.

- Strict Air Quality: Cleanrooms maintain consistent air quality with the help of HEPA or ULPA filters, which remove airborne particles. This clean airflow is crucial in aerospace manufacturing, where the precision of parts depends on the cleanliness of the environment.

Examples of Aerospace Components Manufactured in Cleanrooms:

- Satellite Components: Cleanrooms are essential for assembling satellite parts, such as solar arrays, antennas, and sensitive sensors, where contamination could impact performance in space.

- Aircraft Engine Parts: Components used in aircraft engines must be manufactured with extreme precision. Contaminants like dust or dirt can cause malfunctioning or degradation of parts.

- Spacecraft Electronics: The electronics in spacecraft must function flawlessly under extreme conditions. Cleanrooms provide the ideal environment to assemble and test these complex systems, ensuring reliability during space missions.

Aerospace Cleanroom Requirements: Key Features and Specifications

To meet the demands of the aerospace industry, cleanrooms must adhere to specific cleanroom standards for aerospace that are designed to meet both the performance and safety needs of aerospace technology. Wiselink Group, with its years of experience, ensures that every aerospace cleanroom it designs and installs complies with these stringent standards.

ISO Cleanroom Classification

The ISO 14644 series of standards is a key framework for classifying cleanrooms based on the concentration of airborne particles in a given volume of air. In aerospace, cleanrooms are generally classified at very high levels, often between ISO 1 and ISO 7, depending on the specific requirements of the project.

- ISO 1: The cleanest possible environment with the fewest particles per cubic meter. Used for high-precision aerospace components, such as spacecraft electronics.

- ISO 5 to ISO 7: Suitable for less critical applications, but still offering a controlled environment that meets the aerospace sector’s needs for contamination control.

Airborne Particles and Cleanliness Standards

- Airborne Particle Limits: For aerospace cleanrooms, it’s critical to have highly efficient air filtration systems that keep airborne particles to a minimum. These systems must be able to trap contaminants down to sizes as small as 0.1 microns or smaller.

- Airflow Systems: The design of airflow in cleanrooms, especially in aerospace environments, must be unidirectional to prevent contamination. The airflow should create a positive pressure to prevent particles from entering the cleanroom from outside sources.

Environmental Control Systems

Aerospace cleanrooms must also maintain specific temperature, humidity, and pressure conditions that support the production of sensitive parts. This is especially important in environments that deal with sensitive aerospace components or space manufacturing.

- Humidity Control: Moisture can be detrimental to aerospace components, especially in electronics. Cleanrooms must regulate humidity levels to prevent damage to parts.

- Temperature Control: Components in aerospace manufacturing may have specific temperature tolerances. Cleanrooms must maintain an environment that prevents fluctuations to avoid compromising the integrity of these parts.

Space Manufacturing and Cleanroom Requirements

In addition to traditional aerospace manufacturing, the growing field of space manufacturing requires specialized cleanroom environments that can meet the unique challenges of producing parts for space missions.

Challenges of Space Manufacturing

- Microgravity Effects: In space manufacturing, the absence of gravity can create unique challenges in how materials behave. Cleanrooms used for space manufacturing must account for this by ensuring that particles or contaminants do not interfere with the process.

- Harsh Space Conditions: Space technology needs to withstand extreme conditions, such as radiation and temperature fluctuations. The materials and components used must meet specific standards to ensure they are durable and reliable.

Cleanroom Design for Space Manufacturing

- Vacuum-Sealed Cleanrooms: Cleanrooms that are used for spacecraft assembly may need to be vacuum-sealed to simulate conditions in space and prevent contaminants from affecting sensitive components.

- Sterility and Contamination Control: Space manufacturing involves producing highly sensitive parts that must be sterile and free of contaminants. Cleanrooms ensure that the environment is free from bacteria, dust, and other particles that could interfere with these components.

How Wiselink Group Supports the Aerospace Industry with Cleanroom Solutions

With the increasing demands of the aerospace sector, Wiselink Group provides innovative and customizable cleanroom solutions designed to meet the most stringent requirements. Our cleanrooms are tailored for precision manufacturing, contamination control, and environmental regulation.

Expertise in Aerospace Cleanroom Design

At Wiselink Group, we understand the importance of precision and reliability in the aerospace industry. Our team of experts specializes in designing cleanrooms that are not only compliant with ISO standards but are also customized to meet the unique needs of aerospace technology. Whether you need a cleanroom for satellite assembly, aircraft component manufacturing, or space exploration equipment production, Wiselink Group can provide the right solutions.

- Customized Cleanroom Designs: We work closely with aerospace clients to design cleanrooms that meet their specific requirements, from air filtration systems to temperature control and everything in between.

- Turnkey Solutions: From initial consultation and design to installation and ongoing maintenance, Wiselink Group offers a complete turnkey cleanroom solution for the aerospace sector.

Meeting Aerospace Cleanroom Requirements with Precision

We ensure that every cleanroom meets the necessary aerospace cleanroom requirements for particle count, air cleanliness, humidity, temperature, and pressure. Our cleanroom designs include:

- High-Performance Filtration Systems: Ensuring that airborne particles are kept to a minimum and that cleanrooms meet ISO 14644 standards for the aerospace industry.

- Advanced HVAC Systems: Regulating airflow, temperature, and humidity in cleanrooms to support precise manufacturing processes.

- Space Manufacturing Solutions: For the specialized needs of space manufacturing, we offer custom-designed cleanrooms that account for unique challenges like microgravity and vacuum conditions.

The Future of Aerospace Cleanrooms: Innovations and Trends

As the aerospace industry continues to advance, so too does the technology surrounding cleanrooms for aerospace. Wiselink Group stays at the forefront of cleanroom innovations, ensuring that our solutions are always aligned with the latest industry trends and technological advancements.

Emerging Technologies in Aerospace Cleanroom Design

- Smart Cleanrooms: The use of IoT (Internet of Things) devices and sensors allows for real-time monitoring and control of cleanroom environments. This innovation ensures that any changes in air quality, temperature, or humidity are immediately addressed to maintain contamination-free environments.

- Robotics and Automation: In aerospace cleanrooms, robotics can be used to handle delicate parts, reducing the risk of human error and contamination during manufacturing processes.

- Sustainable Cleanroom Solutions: As sustainability becomes a priority in all industries, Wiselink Group is investing in environmentally friendly cleanroom designs that reduce energy consumption without compromising cleanliness standards.

Cleanrooms as a Pillar of Aerospace Excellence

The aerospace industry demands the highest standards of precision, reliability, and cleanliness. Cleanrooms are at the core of achieving these standards, ensuring that every component is manufactured to exact specifications while remaining free from contaminants that could compromise the integrity of aerospace technology.

At Wiselink Group, we understand the critical importance of aerospace cleanroom requirements and offer tailored solutions to ensure your manufacturing processes meet the most stringent standards. From satellite assembly to spacecraft production, we are committed to providing cleanroom solutions that support the advancement of aerospace technology. Our expertise and dedication to innovation ensure that your cleanroom environment is always at the cutting edge, enabling you to meet the challenges of today and tomorrow’s aerospace industry.