How to Optimize Cleanroom Airflow for Maximum Contamination Control

Written by Wiselink Group Qingdao, China

Cleanroom airflow optimization is an essential aspect of creating an environment that is free from contaminants, a priority in industries like pharmaceuticals, biotechnology, electronics, and medical device manufacturing. Controlling the airflow in these specialized spaces not only maintains regulatory compliance but also ensures the protection of sensitive materials, processes, and even the personnel working within. However, achieving the ideal cleanroom airflow can be a complex task, with various factors influencing its efficiency and overall performance.

At Wiselink Group, we understand that each cleanroom is unique, requiring tailored solutions to optimize airflow and ensure the highest standards of cleanliness. This comprehensive guide will walk you through the key aspects of airflow in cleanrooms, why it’s crucial for contamination control, and the solutions Wiselink Group offers to help you achieve the best airflow for your specific needs.

Understanding Cleanroom Airflow and Its Importance

Cleanroom airflow is more than just moving air within the confines of a room. It is a meticulously controlled system that must manage the direction, velocity, and volume of air to keep contamination at bay. Contaminants such as dust, microbes, and other particles can jeopardize the production or testing of highly sensitive products. The primary purpose of cleanroom airflow is to control the distribution of these airborne particles and to maintain a sterile environment.

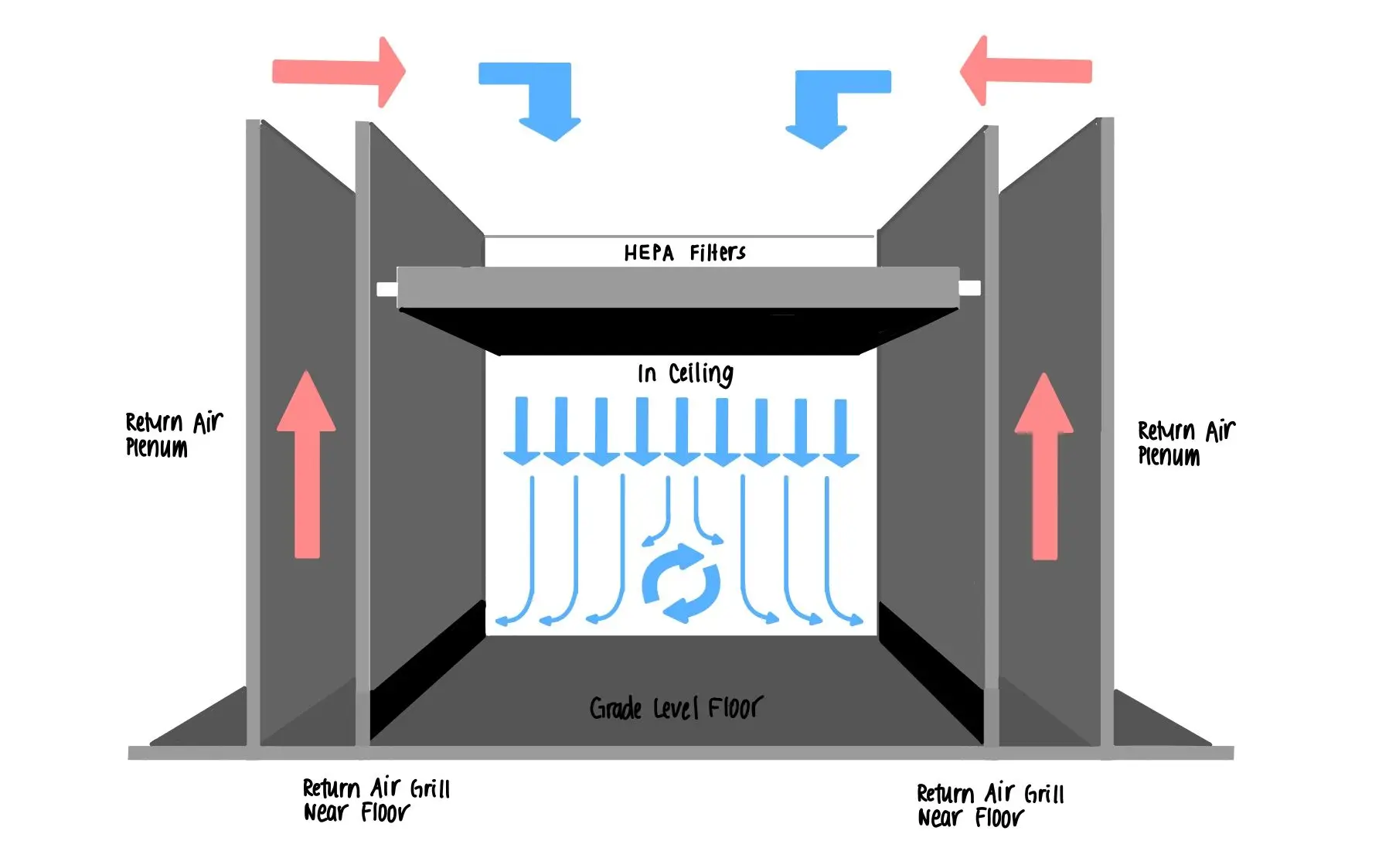

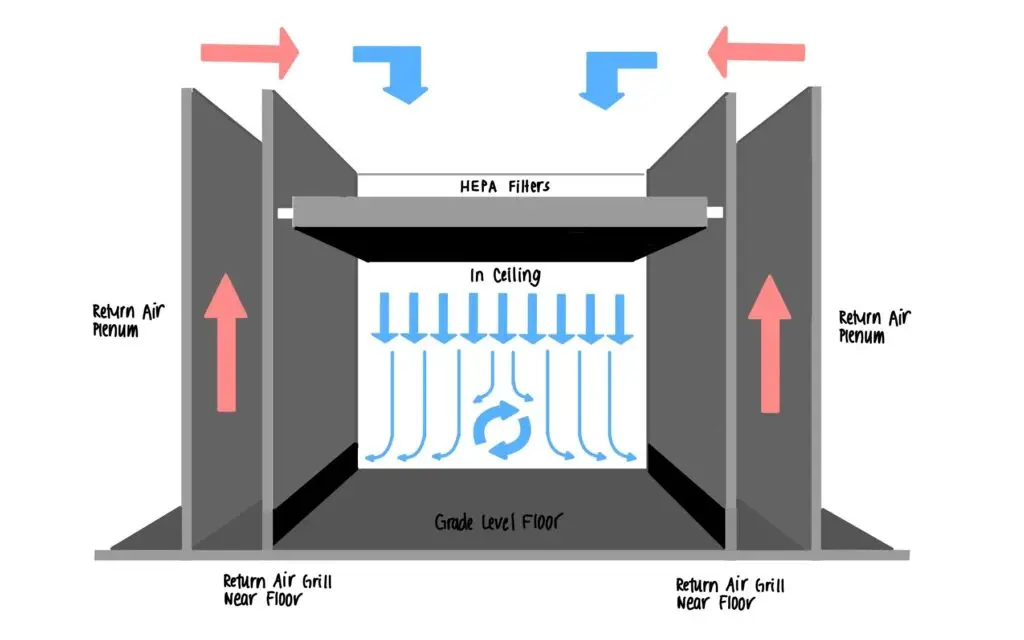

The airflow in cleanrooms can be divided into several types, including laminar flow, turbulent flow, and unidirectional flow. Each of these flow types serves specific purposes and can be utilized in different parts of the cleanroom. Laminar airflow, for instance, is often employed in areas where strict contamination control is required. This type of airflow works by pushing air in a single direction, ensuring that any contaminants are moved out of the critical areas, reducing the chances of contamination.

On the other hand, turbulent airflow is more chaotic and can sometimes be used in less stringent areas of the cleanroom. It’s essential to understand these flow types and their applications within cleanroom environments to determine how best to configure the ventilation system.

Key Elements of Airflow Optimization in Cleanrooms

1. Cleanroom Design

The design of a cleanroom is one of the most important factors when it comes to optimizing airflow. Without a well-thought-out design, maintaining proper airflow can become incredibly challenging. An effective cleanroom layout should incorporate airflow patterns that prevent contamination from accumulating in any one area.

The strategic placement of cleanroom walls, doors, and equipment can direct airflow in a way that ensures maximum efficiency. Additionally, creating zones with different air pressure levels can contribute significantly to minimizing the risk of cross-contamination between areas with varying cleanliness standards.

For example, the installation of airlocks and gowning rooms plays a key role in maintaining positive air pressure and reducing the potential for contaminants entering sensitive areas.

2. Airflow Velocity

The speed at which air moves through the cleanroom is another critical factor in ensuring effective contamination control. Air velocity is measured in feet per minute (FPM) and refers to how fast air moves through filters or the space itself. Too high of an airflow velocity can disturb particulate matter, while too low can result in insufficient air changes, allowing contaminants to remain.

An ideal air velocity can vary depending on the cleanroom class and the type of work being done. For example, an ISO Class 5 cleanroom will require a higher air velocity than a Class 7 cleanroom to ensure that the airflow is adequate to maintain the cleanliness standards.

3. Air Changes per Hour (ACH)

Air changes per hour (ACH) refers to the number of times the entire volume of air in a cleanroom is replaced within an hour. A higher ACH ensures that any airborne particles are removed from the cleanroom environment more rapidly. Generally, the higher the ACH, the cleaner the environment. For highly sensitive cleanrooms, such as those in the semiconductor or pharmaceutical industries, an ACH of 100 or more may be necessary.

Balancing ACH with other factors such as airflow velocity and filtration capacity is essential to optimizing overall cleanroom performance. Achieving this balance can be challenging, but with the right systems in place, it can significantly improve air quality.

4. Filtration Systems

Filtration systems are at the heart of cleanroom airflow optimization. The most commonly used filters in cleanrooms are HEPA (High-Efficiency Particulate Air) and ULPA (Ultra-Low Penetration Air) filters. These filters are designed to capture and remove airborne particles from the air, ensuring that only clean, filtered air circulates throughout the room.

The placement of these filters and the selection of the right filter type for your cleanroom’s needs will depend on several factors, including the size of the room, the classification, and the type of contamination control required. For instance, HEPA filters are often sufficient for Class 7 and Class 8 cleanrooms, while ULPA filters are necessary for stricter environments like Class 5 cleanrooms.

Properly maintaining and regularly replacing filters is crucial to ensure the cleanroom’s performance remains optimal over time.

Why Choose Wiselink Group for Cleanroom Airflow Optimization?

At Wiselink Group, we offer a wide range of high-quality products and services that are tailored to optimize cleanroom airflow. Our expertise lies in designing and delivering modular cleanroom solutions, airflow management systems, and filtration systems that provide maximum contamination control.

Here are a few reasons why you should choose Wiselink Group for all your cleanroom airflow optimization needs:

Expertise and Experience

With years of experience in cleanroom design and manufacturing, Wiselink Group offers specialized solutions that are customized to meet the unique demands of your industry. We understand the critical nature of maintaining optimal airflow and contamination control, and our team of experts works closely with you to ensure the highest standards are met.

High-Quality Products

We supply state-of-the-art HEPA and ULPA filters, HVAC systems, and modular cleanroom panels that ensure superior performance. All our products are manufactured to the highest standards, ensuring reliability and durability.

Comprehensive Services

From cleanroom design and installation to ongoing maintenance and upgrades, Wiselink Group offers comprehensive services to support the continuous optimization of your cleanroom environment. Our modular solutions make it easy to scale and reconfigure your cleanroom as your operational needs evolve.

Compliance and Certification

Our cleanroom solutions are designed to meet the most stringent industry standards, including ISO and GMP compliance. Whether you’re in pharmaceuticals, biotechnology, or electronics, our products are built to help you meet regulatory requirements with ease.

Optimize Your Cleanroom Airflow Today with Wiselink Group

Optimizing your cleanroom airflow is critical to maintaining high-quality standards and ensuring contamination-free environments. At Wiselink Group, we provide tailored cleanroom solutions that include state-of-the-art filtration systems, modular designs, and airflow management systems to keep your operations running smoothly and efficiently.

If you’re ready to enhance the performance of your cleanroom and achieve the best airflow optimization for maximum contamination control, contact Wiselink Group today. Let our team of experts assist you in creating a cleaner, more efficient environment.