Isomeric Forms in Cleanroom Ventilation Systems: Importance and Design

Cleanroom environments are crucial in industries like pharmaceuticals, electronics, and biotechnology, where air quality, cleanliness, and precise control of environmental factors are paramount. One of the most important components of maintaining a controlled environment in cleanrooms is the ventilation system. Proper ventilation is essential to minimize contamination, maintain temperature and humidity levels, and ensure the safety and efficiency of sensitive processes.

However, understanding the role of isomeric forms in this context is often overlooked, despite their critical role in chemical interactions and material handling. This blog will explore what isomeric forms are, why they matter in cleanroom environments, and how they impact the design and operation of cleanroom ventilation systems.

Understanding Isomeric Forms

Before diving into their role in cleanroom ventilation systems, it’s important to understand what isomeric forms are. Isomers are molecules that have the same chemical formula but differ in the arrangement of their atoms. These structural differences lead to different physical and chemical properties, which can impact various processes, including those in cleanroom environments.

There are two main types of isomeric forms:

Structural Isomers: These isomers differ in the connectivity of their atoms. This can influence their reactivity, volatility, and overall stability.

Stereoisomers: These isomers have the same atomic connections but differ in the spatial arrangement of atoms. This is particularly important in chemical reactions, as different stereoisomers can have vastly different properties, especially in biological systems.

In cleanroom environments, understanding and controlling the behavior of these isomers can be crucial, particularly when dealing with sensitive chemical processes or materials.

Why Isomeric Forms Matter in Cleanrooms

In cleanrooms, where contaminants are carefully controlled and processes are sensitive, the presence and behavior of different isomeric forms can directly influence the success or failure of a process. Whether you’re working with pharmaceutical compounds, electronics, or nanomaterials, the purity of substances is key. Isomeric forms can have subtle, yet significant effects on the quality and consistency of products.

Chemical Stability and Reactivity: Certain isomers may react differently to heat, light, or air exposure. Understanding these variations is essential when designing ventilation systems that regulate airflow, temperature, and humidity.

Airborne Contaminants: The release of certain isomers into the air can result in chemical contaminants that compromise the cleanroom environment. For instance, certain isomeric forms may volatilize more easily than others, which could lead to the contamination of sensitive equipment or materials.

Control of Chemical Processes: In cleanrooms, where chemical processes often take place, controlling the behavior of isomers ensures that reactions occur under optimal conditions, minimizing waste and improving efficiency.

Designing Cleanroom Ventilation Systems to Handle Isomeric Forms

A cleanroom’s ventilation system must be designed to handle the unique challenges posed by isomeric forms. This involves several key factors:

1. Airflow Design and Contaminant Control

Proper airflow is essential for maintaining the cleanliness of a cleanroom. Air must flow in a manner that minimizes contamination, but it also needs to be designed to handle volatile isomeric compounds. This means that ventilation systems must be equipped to filter out harmful chemicals, manage air pressure, and ensure consistent airflow patterns that prevent the buildup of harmful isomeric substances.

2. Temperature and Humidity Regulation

Temperature and humidity control is vital in preventing the degradation or unintended chemical reactions of certain isomers. For example, high humidity levels can increase the volatility of certain isomers, leading to contamination or unstable reactions. Cleanroom ventilation systems must therefore incorporate advanced climate control features that regulate both temperature and humidity levels.

3. Specialized Filters and Air Scrubbers

To mitigate the risks associated with volatile isomeric compounds, cleanroom ventilation systems should include high-efficiency filters, such as HEPA (High-Efficiency Particulate Air) filters or activated carbon filters. These filters can trap airborne isomers and other volatile substances, preventing them from contaminating the cleanroom space.

4. Control Systems for Real-Time Monitoring

Advanced control systems that monitor air quality in real-time are essential for ensuring that ventilation systems are responding dynamically to changing conditions in the cleanroom. These systems can track the levels of specific isomers and adjust airflow, temperature, and filtration rates accordingly to prevent contamination.

The Role of Wiselink Group in Cleanroom Ventilation and Isomeric Sales

Wiselink Group provides solutions that address both the ventilation needs of cleanrooms and the sales of isomers. The company specializes in supplying high-quality isomeric forms, ensuring that businesses working in cleanroom environments have access to pure, stable chemicals that meet industry standards.

Wiselink Group’s Products for Cleanroom Ventilation Systems

Wiselink Group not only provides isomers but also offers expert solutions in cleanroom system design, ensuring that your facility meets the strictest regulatory standards. Their services include:

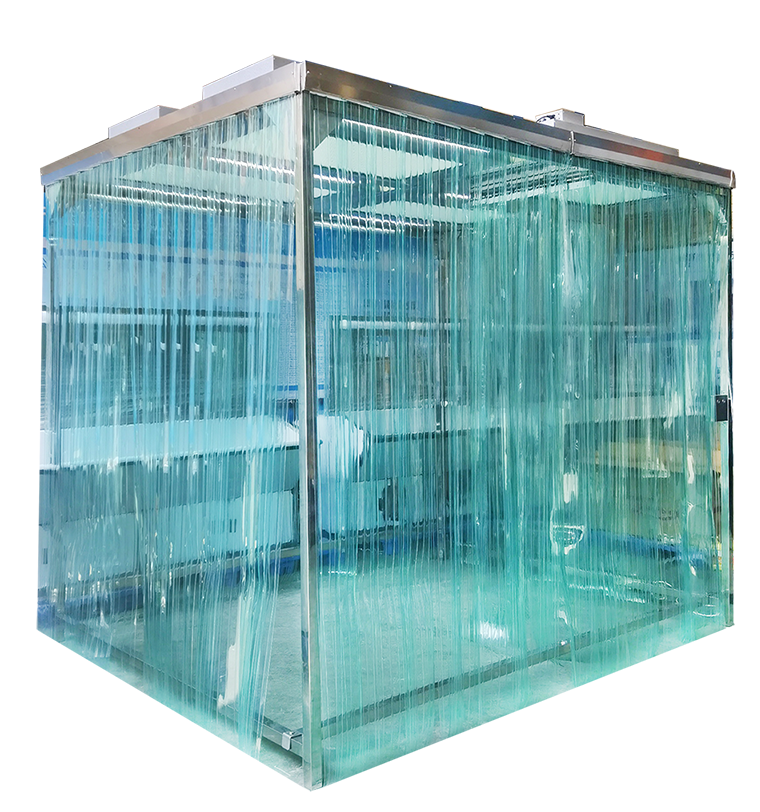

- Custom Cleanroom Design: Tailoring ventilation and air handling systems to meet the unique requirements of isomer-sensitive processes.

- Isomeric Form Supply: Wiselink provides a wide range of isomers, ensuring that your processes run smoothly and without the risk of contamination.

- Contamination Control Solutions: Implementing filtration and airflow systems designed to prevent the release of isomeric contaminants into the cleanroom environment.

Optimizing SEO for Cleanroom Ventilation and Isomeric Forms

To ensure this article is optimized for SEO, we’ll focus on the following key areas:

- Keyword Integration: Throughout the blog, keywords like “isomeric forms,” “cleanroom ventilation systems,” “isomeric compounds,” and “air quality control” will be naturally integrated into headers, subheaders, and body content.

- Meta Descriptions and Tags: The meta description will include a concise, keyword-rich summary, such as:

“Learn about the importance of isomeric forms in cleanroom ventilation systems. Discover how to optimize air quality and prevent contamination with the right design and solutions from Wiselink Group.” - Internal Linking: The blog will include internal links to other relevant articles or product pages from Wiselink Group’s website, such as those on their isomer sales or cleanroom design services.

Call to Action (CTA)

To convert readers into leads, the blog will include a clear call to action. Here’s an example CTA section that can be placed towards the end of the blog:

Get the Best Cleanroom Ventilation Solutions Today

Are you looking to optimize your cleanroom environment and ensure the highest level of air quality control? Wiselink Group is your trusted partner for designing top-notch cleanroom ventilation systems and supplying pure, stable isomeric compounds for your processes.

Contact Wiselink Group today to learn more about how our solutions can help you meet industry standards and maintain a contamination-free cleanroom environment.

Conclusion

In conclusion, understanding the role of isomeric forms in cleanroom ventilation systems is essential for ensuring the stability, safety, and effectiveness of processes that depend on air quality. The right ventilation system, combined with high-quality isomeric compounds, can make all the difference in maintaining a contamination-free environment. Wiselink Group is committed to providing both advanced cleanroom design solutions and high-quality isomers to meet the needs of businesses in industries that rely on precise and controlled environments.

By leveraging Wiselink Group’s expertise and products, you can ensure that your cleanroom processes run smoothly and efficiently, without compromising on quality or safety.