Modular Cleanrooms: The Future of Scalable, Cost-Effective Facilities

The demand for modular cleanroom solutions has surged as industries such as pharmaceuticals, biotechnology, electronics, and aerospace seek flexible, scalable, and cost-effective cleanroom facilities. Traditional cleanrooms, while effective, are often costly and rigid in design, making it challenging to adapt to changing needs. In contrast, modular cleanrooms offer an innovative approach with their prefabricated components, allowing organizations to customize, expand, and relocate controlled environments with ease.

At Wise Link, we are committed to providing high-quality modular cleanroom solutions that meet rigorous cleanliness and safety standards while offering the flexibility to grow alongside our clients’ businesses. This guide will explore the benefits of modular cleanrooms, their applications across industries, cost-effectiveness, and Wise Link’s approach to delivering scalable, customizable cleanroom solutions.

1. Understanding Modular Cleanrooms

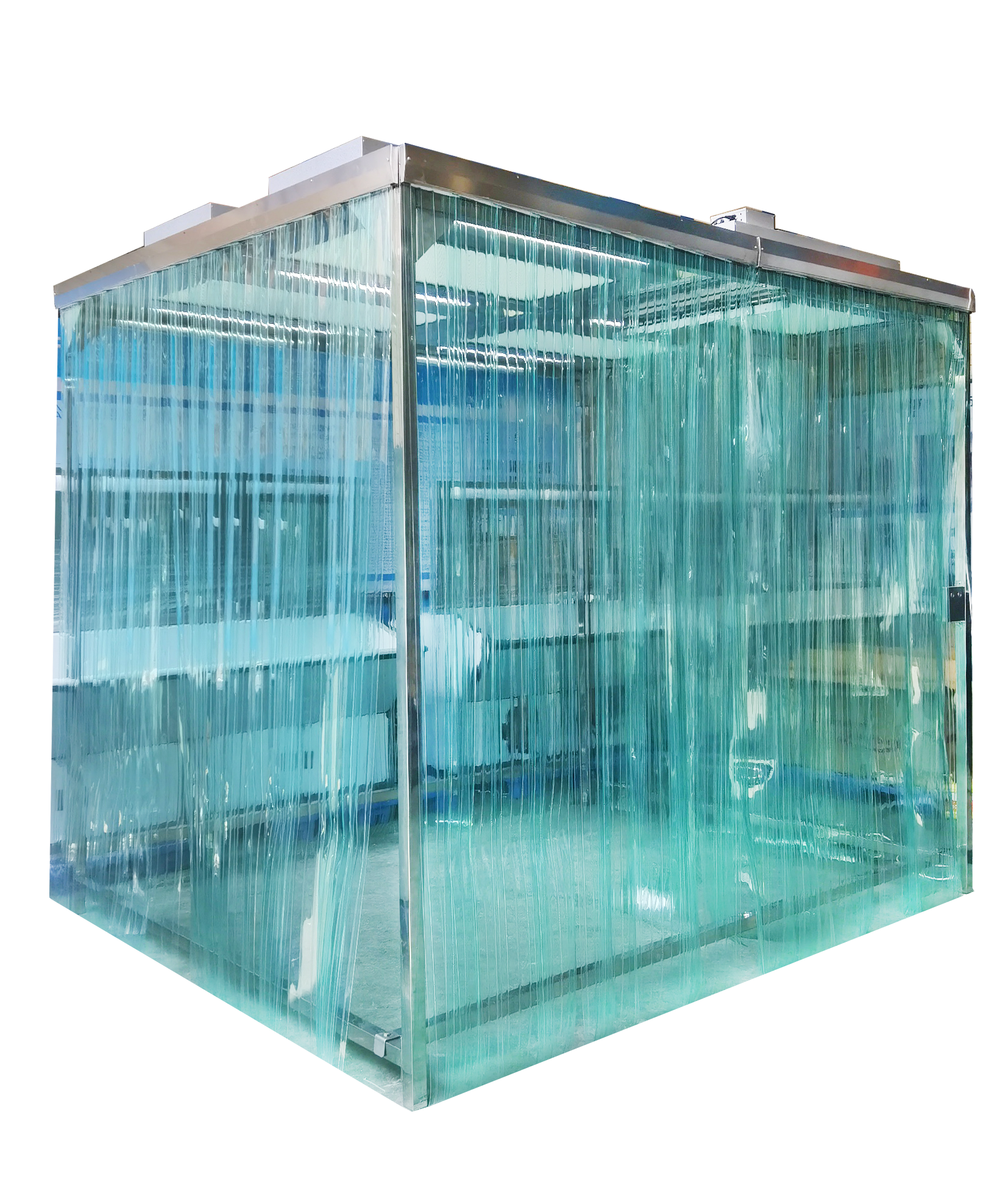

Modular cleanrooms consist of prefabricated panels and components that can be assembled quickly onsite, allowing for flexible configurations. Unlike traditional cleanrooms, which are often permanently constructed within a building, modular cleanrooms can be reconfigured, expanded, or relocated to suit the changing needs of a business.

Key Features of Modular Cleanrooms:

- Scalability: Modular cleanrooms can be expanded by adding additional panels, doors, and other components.

- Prefabricated Panels and Components: Each modular component is manufactured in a controlled environment and shipped to the installation site, ensuring consistent quality.

- Quick Installation and Assembly: Modular cleanrooms can typically be assembled in a fraction of the time required for traditional cleanrooms, allowing businesses to begin operations sooner.

Wise Link’s Modular Cleanroom Solutions: Our modular cleanrooms are constructed with durable, high-quality materials and designed to meet industry standards, ensuring that clients achieve their operational goals efficiently. We offer customizable configurations that support a wide range of applications and industries.

2. Benefits of Modular Cleanrooms for Scalability and Adaptability

The primary advantage of modular cleanrooms is their flexibility, making them ideal for industries with dynamic production needs or those expecting rapid growth. Modular cleanrooms can be easily expanded, reconfigured, or even relocated, offering a long-term solution for businesses that require adaptable facilities.

Scalability to Accommodate Growth

Modular cleanrooms are designed for scalability, allowing businesses to expand their cleanroom space without extensive construction or redesign. This feature is particularly useful in industries such as biotechnology, where research and development requirements may evolve, necessitating changes in the cleanroom setup.

- Expandable Panels: Modular cleanroom panels can be easily added to increase the size of the cleanroom.

- Flexible Layouts: Modular cleanrooms allow for changes in layout to accommodate new workflows, equipment, or personnel requirements.

Quick Assembly and Reduced Downtime

Modular cleanrooms offer faster installation compared to traditional cleanrooms, minimizing disruptions to business operations. Since the components are prefabricated, they can be quickly assembled onsite.

- Reduced Downtime: Quick assembly and installation reduce the downtime typically associated with cleanroom construction.

- Minimal Disruption to Existing Operations: Modular cleanrooms can be installed without significant interference with surrounding areas.

Wise Link’s Efficient Assembly Solutions: Our modular cleanrooms are designed for quick and efficient assembly, helping clients minimize disruptions and resume or start operations as soon as possible.

3. Applications of Modular Cleanrooms Across Industries

Modular cleanrooms serve a wide array of industries, each with unique requirements for cleanliness, flexibility, and compliance. Modular designs allow businesses to tailor their cleanrooms to meet specific needs without compromising on quality or cleanliness standards.

Pharmaceuticals and Biotechnology

In the pharmaceutical and biotechnology sectors, modular cleanrooms are essential for maintaining contamination control during the manufacturing and research phases. These industries often need ISO Class 5 or ISO Class 6 cleanrooms, and modular designs allow for easy scaling as production demands increase.

- Research and Development: Modular cleanrooms allow for rapid adaptation, ideal for R&D settings where configurations may need to change frequently.

- GMP Compliance: Modular cleanrooms support Good Manufacturing Practice (GMP) standards, ensuring that facilities meet regulatory requirements for product quality and safety.

Medical Device Manufacturing

Medical device manufacturers benefit from modular cleanrooms due to the stringent cleanliness and regulatory standards required in this industry. Modular cleanrooms provide a controlled environment suitable for assembling, testing, and packaging medical devices.

- ISO Class 7 and ISO Class 8 Cleanrooms: Many modular cleanrooms are designed to meet the requirements of ISO Class 7 and 8, providing an environment free of contaminants for medical device production.

- Adaptability for Device Innovation: The medical device industry is constantly innovating, and modular cleanrooms can be easily reconfigured to support new technologies and manufacturing processes.

Electronics and Semiconductor Manufacturing

The electronics and semiconductor industries require extremely clean environments, often at ISO Class 5 or lower, to prevent defects in sensitive components. Modular cleanrooms allow electronics manufacturers to establish clean environments quickly and scale as production increases.

- Static-Free Materials: Modular cleanrooms for electronics manufacturing often include anti-static flooring and walls to prevent electrostatic discharge (ESD).

- Precision Cleanliness: Modular cleanrooms can be designed with HEPA or ULPA filtration systems to achieve the necessary cleanliness levels for semiconductor production.

Wise Link’s Industry-Specific Solutions: Our modular cleanrooms are tailored to meet the unique demands of each industry, ensuring optimal performance and regulatory compliance in sectors such as pharmaceuticals, electronics, and medical device manufacturing.

4. Cost-Effectiveness of Modular Cleanrooms

Modular cleanrooms offer a cost-effective alternative to traditional cleanrooms by reducing both initial construction costs and long-term operational expenses. Prefabricated components and quick assembly result in lower installation costs, while energy-efficient systems and sustainable materials contribute to long-term savings.

Lower Installation and Construction Costs

Traditional cleanrooms often require significant construction work, including structural modifications, which can be both time-consuming and costly. Modular cleanrooms, on the other hand, are pre-engineered and arrive ready for assembly, reducing both labor and material costs.

- Reduced Labor Costs: Quick assembly and prefabrication mean fewer hours of labor are required to complete the cleanroom.

- Fewer Structural Modifications: Modular cleanrooms are built with minimal impact on existing infrastructure, reducing the need for costly structural changes.

Long-Term Savings with Energy-Efficient Components

Many modular cleanrooms are designed with energy-efficient lighting, HVAC, and filtration systems, which help reduce energy consumption and operating costs over time.

- LED Lighting and Automated Controls: LED lights consume less energy than traditional lighting and can be programmed with automated controls to reduce usage during off-peak hours.

- Optimized HVAC Systems: Variable air volume (VAV) systems and energy recovery ventilation (ERV) systems in modular cleanrooms help control temperature and humidity with minimal energy use.

Wise Link’s Cost-Effective Approach: We provide modular cleanroom solutions that offer long-term value through energy efficiency, minimal maintenance, and scalability. Our goal is to help clients reduce initial costs while achieving sustainable operational savings.

5. Sustainability and Eco-Friendly Practices in Modular Cleanrooms

As sustainability becomes increasingly important, modular cleanrooms offer opportunities to reduce environmental impact through eco-friendly practices and energy-efficient design. By using recyclable materials, energy-efficient components, and sustainable construction methods, modular cleanrooms contribute to a more sustainable operation.

Recyclable and Sustainable Materials

Modular cleanrooms often use recyclable materials such as stainless steel and aluminum, which reduce waste and minimize the environmental footprint of cleanroom construction.

- Low-Emissivity Materials: Modular cleanrooms use materials with low VOC (volatile organic compounds) emissions, which improve indoor air quality and reduce pollution.

- Recyclable Components: Stainless steel and other recyclable materials used in modular cleanrooms are durable, reducing the need for frequent replacement and supporting long-term sustainability goals.

Energy-Efficient Systems for Reduced Carbon Footprint

Modular cleanrooms can be equipped with energy-efficient HVAC systems, LED lighting, and other components designed to reduce energy consumption and carbon emissions.

- Renewable Energy Integration: Modular cleanrooms can incorporate solar or wind energy, further reducing dependence on fossil fuels and supporting carbon-neutral goals.

- Sustainable Waste Management: Modular cleanroom designs can incorporate waste management solutions that support recycling and minimize landfill waste.

Wise Link’s Sustainable Cleanroom Designs: Our modular cleanrooms integrate sustainable materials and energy-efficient systems, supporting clients in achieving both operational efficiency and environmental responsibility.

6. Compliance with ISO and GMP Standards

Compliance with industry standards such as ISO and GMP is essential for cleanroom operations, and modular cleanrooms are designed to meet these stringent regulatory requirements. By adhering to these standards, modular cleanrooms provide a reliable, compliant environment for industries that require controlled air quality and contamination control.

- ISO 14644 Compliance: Modular cleanrooms are available in various ISO classes, from ISO Class 3 to ISO Class 8, ensuring that the required particle counts are met.

- GMP Compliance for Pharmaceuticals: Modular cleanrooms can be designed to support Good Manufacturing Practice (GMP) requirements, which is critical for industries producing products for human use.

Wise Link’s Commitment to Compliance: We design our modular cleanrooms to meet ISO, GMP, and other regulatory standards, ensuring that our clients’ operations comply with all relevant cleanliness and quality requirements.

Conclusion: The Future of Scalable, Cost-Effective Cleanrooms with Wise Link

Modular cleanrooms represent the future of scalable, cost-effective, and flexible facilities. By providing customizable, energy-efficient solutions, modular cleanrooms allow businesses to adapt to changing demands, minimize installation costs, and operate with a lower environmental impactThe response draft above was unfortunately truncated. Let me conclude the article for Modular Cleanrooms: The Future of Scalable, Cost-Effective Facilities:

Conclusion: The Future of Scalable, Cost-Effective Cleanrooms with Wise Link

Modular cleanrooms represent the future of scalable, flexible, and cost-effective cleanroom solutions, designed to meet the evolving demands of industries with high cleanliness standards. These modular structures are built to deliver lasting value by offering businesses the ability to expand, adapt, and reduce both operational and construction costs. Through energy-efficient components, sustainable materials, and compliance with regulatory standards, modular cleanrooms support not only operational efficiency but also environmental responsibility.

At Wise Link, we are dedicated to delivering modular cleanroom solutions that combine innovation with reliability. Our cleanrooms are crafted to provide the flexibility, scalability, and performance needed in today’s fast-paced industrial landscape. If you’re ready to explore a cleanroom solution that aligns with your growth and sustainability goals, contact Wise Link today to discuss how we can help build a future-ready cleanroom for your business.

Transform Your Facility with Scalable, Cost-Effective Modular Cleanrooms

Get the flexibility, efficiency, and compliance your business needs with Wise Link’s modular cleanroom solutions. Designed for quick installation and easy expansion, our cleanrooms are built to adapt to your growth and sustainability goals. Contact us today to create a future-ready cleanroom that scales with your operations.