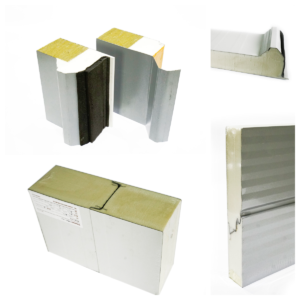

Polyurethane sandwich panels, or PU Sandwich Panels, are made of two layers of colored steel sheets that are resistant to weather and are filled with strong polyurethane between two layers of materials that are fireproof. This material is appropriate for a variety of roofs and walls, including those on large-scale factory buildings, storage facilities, exhibition halls, gymnasiums, freezing stores, purification workshops, and so on. It has the qualities of being weatherproof, heat-resistant, temperature-regulating, and aesthetically pleasing.

It is widely applicable in the petroleum, chemical, building, packaging, refrigeration, military, space, aviation, transportation, and industrial model design industries as a structural and heatproof material.

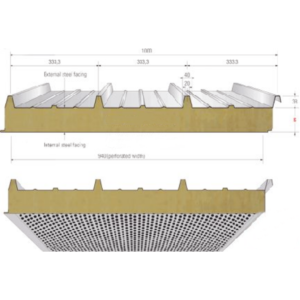

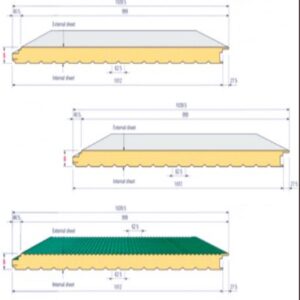

| Type | Polyurethane Sandwich Panels(PU, PUR, PIR) |

| Panel Material | Color steel sheet, Galvanized steel, Stainless steel sheet, or other. |

| Place of Origin | China |

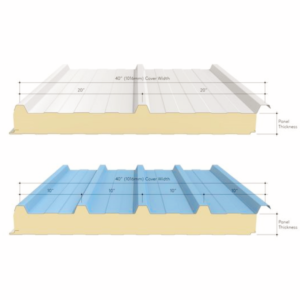

| Length | Customize( At most 23meters) |

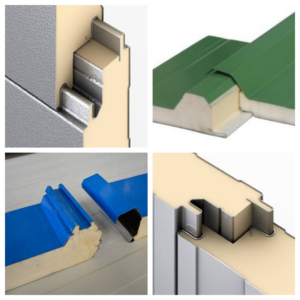

| Effective Width | 960mm(cam-lock); 1120mm( Fast-ft) |

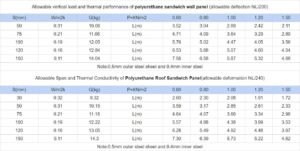

| Core thickness | 50mm, 75mm, 100mm, 120mm, 150mm, 175mm, 200mm, 250mm |

| Features | Insulation,Soundproof, fireproof, waterproof |

| Certificates | SGS, ISO14001, ISO9001 |

| Color | White, Gray, Sliver, Whit gray…etc, as required |

| Lifetime | 10-30 years |

| Fire proof rate | B1, B2 |

| Usage | In different fields: Food storage, Lab center, Medicine factory, Logistics Center, Cold Drinks Processing Center …ect |

PUR products use the most cutting-edge six component online automatic (SIMENS) mixing and pouring technology available worldwide for raw material proportioning and process output. This allows them to achieve six-component continuous foaming for the first time in China.With the use of technology, the mixing and proportioning process can be completed online; the formula can be modified in response to changes in the environment; air feeding and mixing devices can be used to improve the evenness of raw material mixing and the fineness of the foam produced, resulting in the production of high-strength, energy-efficient, and environmentally friendly building boards.

We can refer to polyisocyanurate as PIR in short. In order to create compact PIR products for the composite boards, extra isocyanurate is used, and ring structure and a higher isocyanurate index are used in the compounds. This ensures better stability and superior fire and heat resistance for the interior stiff foams. Tests indicate that the goods can withstand temperatures as high as 200ºC for brief periods of time or as low as 160ºC for extended periods of time.

Polyurethane Wall/Roof Sandwich Panel for Cold Room, Storage, and Prefabricated Homes in PIR/PUR/PUExpanded plastics, known as PIR/PUR/PU Polyurethane Wall/Roof Sandwich Panel for Cold Room/Storage/Prefab House, are created when isocyanates react with polyaddition in the presence of activating and stabilizing agents. We utilize pentane, a conventional hydrocarbon that is completely safe for the ozone layer, as the blowing agent. We obtain additional aromatic bonding in polyisocyanurate (PIR/PIR+) foams by employing certain polyester-derived polyols. Additionally, polyisocyanurate rings with strong chemical resistance can be created under the right circumstances by raising the so-called index. Consequently, three-dimensional structures are obtained in the PIR/PIR+ foam as opposed to flat rings in the PUR foam.

We offer a range of Headstream PIR-cored fire resistant insulated panels for all types of temperature controlled applications & controlled environment projects.

The high thermal performance of the PIR (PolyIsoCyanurate) core offers higher energy savings and/or reduced thicknesses of construction when compared to other insulated panel systems. They are fire resistant, hygienic and fibre free.

1.What is a PU sandwich panel used for?

Sandwich panels are used as cold storage panel in buildings such as cold rooms and cold storages which requires certain air-conditioning features, based on their thermal insulation feature. Cold storage panels maintain the desired temperature and control the heating and cooling process.

2.What is the difference between PIR and PU sandwich panels?

(1) Difference in fire resistance: PU foam: generally B3 grade, by adding flame retardants, it can reach B2 grade. PIR foam: generally B2 grade, by adjusting the concentration of polyisocyanurate acid ring and other formula technology, it can reach the B1 level, and the oxygen index can reach more than 35%.

3. What is the life expectancy of a PU panel?

For example, under normal wear and tear, a durability of more than 50 years can be expected for polyurethane insulation systems for buildings, more than 25 years for polyurethane used for insulation of refrigerators or more than 20 years for the application of polyurethane in vehicle bumpers.

Wise Link’s main products include clean room panels, clean room Aluminum frame/steel frame doors, clean room double glass windows, clean room dynamic pass boxes, FFU, clean room LED light, and so on.