In the vast realm of construction and manufacturing, the choice of materials plays a pivotal role in determining the longevity and efficiency of structures. Among the various options available, sandwich panels have gained significant popularity due to their versatility and excellent thermal insulation properties. However, the key lies not only in choosing sandwich panels but in selecting the right sandwich panel manufacturer.

This article delves into the intricacies of sandwich panel manufacturers, providing insights into the considerations, top players, pricing factors, sustainability efforts, challenges, and future trends.

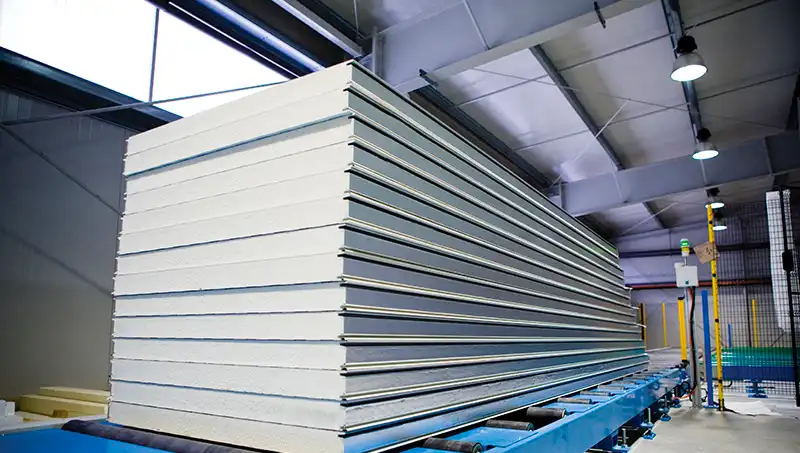

What Are Sandwich Panels?

Sandwich panels, a composite material, consist of two outer layers bonded to a core material, often made of insulating materials. Widely used in construction and manufacturing, these panels offer lightweight yet robust solutions for diverse applications. Whether in building facades, cold storage, or industrial structures, sandwich panels provide an efficient and cost-effective solution.

Top Sandwich Panel Manufacturers

1. Paneltech

Established in 1989, PanelTech Ltd boasts a rich history in the market, leveraging decades of experience and strategic investments in cutting-edge process lines. Our specialization lies in crafting top-notch construction materials, with a primary focus on the production of high-quality sandwich panels, polystyrene, and industrial doors. Our commitment to excellence has earned us the trust of numerous satisfied clients, both domestically and internationally.

As a testament to our global reach, we currently export our products to nearly 30 countries across the world. At PanelTech, we are synonymous with reliability, precision in meeting deadlines, and the delivery of products and services of the highest quality. Client satisfaction is not just a goal but our paramount priority. Choose PanelTech for unparalleled craftsmanship and a commitment to exceeding your expectations.

2. Sandwich Panel Group

At Panel Sandwich Group, they operate multiple state-of-the-art production centers across Spain, dedicated to crafting a diverse array of custom sandwich panels, catering to the extensive needs of the European market.

Their global footprint extends beyond Spain, with a network of correspondents and strategic business partners spanning 8 countries. International expansion is a cornerstone of our growth strategy, positioning us as a current benchmark for excellence. Notably, they are recognized as one of the thousand fastest-growing companies in the European Union, a distinction awarded by the Financial Times in both 2018 and 2022.

3. Epack Prefab

Established in 1999 at the prime location of Greater Noida, EPACK Prefab stands as an ISO 9001-2015 and ISO 14001:2015 accredited leader in the manufacturing of sandwich panels.

As pioneers in engineering, fabrication, and project management, they offer a comprehensive Total Pre-Engineered Building Solution. Their expertise extends beyond Pre Engineered Steel Buildings; EPACK Prefab operates cutting-edge manufacturing facilities for cold roll-formed sections, providing intricate profiles tailored to meet the diverse requirements of industries such as Airport Terminals, Logistics, Construction, Automobiles, Railways, Material Handling, Power Generation, Hospitals, Schools, and more.

4. Tekno Panel

As a leading sandwich panel manufacturer, Teknopanel has been dedicated to delivering world-class services and innovative solutions since its establishment in 2005. They operate under the Teknopanel umbrella, encompassing four distinct brands: Teknopanel Sandwich Panels, Deltapan, Teknopor EPS Products, and Teknosistem Exterior Thermal Insulation Systems.

Their state-of-the-art facilities, specializing in the production of Sandwich Panels, EPS Products, and Trapezoidal Sheets, stand among the most cutting-edge production centers in Europe. Thanks to a proficient R&D team and strategic investments, Teknopanel offers swift and effective solutions with a substantial production capacity of 13.5 million m² for Sandwich Panels and 1.6 million m³ for EPS.

With a commitment to excellence, Teknopanel proudly exports its products to five continents, spreading their expertise globally. Their success is reflected in their inclusion in Istanbul Chamber of Industry’s Top 500 Industrial Enterprises list, solidifying their position as a leading company in the industry. With 460 employees and around 100 Authorized Service Points, they are dedicated to continuous improvement, striving to evolve into a globally recognized brand.

5. Brucha America

As a prominent player in insulated metal panel technology, they are BRUCHA, a leading manufacturer catering to the Industrial, Commercial, Architectural, Cold Storage, Foodservice, and Retail sectors. With nearly 1 million sq. ft. of production space at their European headquarters in Austria, 19 global subsidiaries, and three U.S. sales offices in Denver (CO), Chicago (IL), and Houston (TX), they have been a pivotal force in the industry for the last 70 years.

As a 4th generation, family-owned and operated business, their commitment to excellence is evident in their dedication to shaping the industry. BRUCHA prides themselves on delivering energy-efficient and cost-effective insulated metal wall and roof panels. Their mission extends beyond product excellence; they are steadfast in providing customers with cutting-edge design innovations and technological advancements while actively contributing to international sustainability efforts.

Key Considerations Choosing Sandwich Panel Manufacturer

Selecting the right sandwich panel manufacturer is a pivotal decision that significantly impacts the success and longevity of your project. Here, we delve deeper into key considerations to guide you through this crucial process:

Quality of Materials

The foundation of any reliable sandwich panel lies in the quality of its materials. Assess the composition of the panels offered by manufacturers. High-quality materials ensure durability, resistance to wear and tear, and long-term structural integrity. Inquire about the specific materials used for both the outer layers and the core, ensuring they meet industry standards and your project requirements.

Production Processes and Technology

Understanding the manufacturing processes employed by a company is vital. Advanced technology and efficient production methods contribute not only to the quality of the panels but also to the speed and precision of the manufacturing process. Inquire about the machinery, automation, and quality control measures in place. Manufacturers utilizing cutting-edge technology often produce panels with consistent quality.

Customization Options

Every project is unique, and the ability to customize sandwich panels according to specific requirements is a key consideration. A manufacturer offering a range of customization options, such as varying panel thicknesses, sizes, and finishes, provides flexibility to adapt to diverse project needs. Ensure that the manufacturer can tailor the panels to meet your project’s specifications, contributing to a seamless integration into your design.

Compliance with Industry Standards

A reliable manufacturer adheres to industry standards and certifications. Check for certifications that validate the quality and safety of their products. ISO certifications and compliance with relevant building codes and standards ensure that the panels meet regulatory requirements. Manufacturers transparent about their adherence to these standards demonstrate a commitment to delivering products of the highest caliber.

Testing and Quality Assurance Protocols

Thorough testing and quality assurance are integral to the manufacturing process. Inquire about the testing procedures employed by the manufacturer to ensure that panels meet or exceed specified performance criteria. Manufacturers conducting rigorous testing, including assessments of thermal conductivity, fire resistance, and structural integrity, instill confidence in the reliability of their products.

Durability and Longevity

Consider the expected lifespan of the sandwich panels. Reliable manufacturers provide information on the durability of their products, detailing factors such as resistance to corrosion, weathering, and other environmental stressors. Understanding the longevity of the panels is crucial for making informed decisions, especially for projects with specific durability requirements.

Innovations and Research Initiatives

Manufacturers invested in research and development often lead the industry in terms of innovation. Inquire about a manufacturer’s commitment to staying abreast of technological advancements and incorporating new materials or processes. Those at the forefront of innovation are more likely to offer panels that align with the latest industry trends and provide enhanced performance.

Supply Chain Transparency

The transparency of a manufacturer’s supply chain is a reflection of their commitment to ethical and sustainable practices. Inquire about the sourcing of raw materials, ensuring they come from reputable suppliers. Manufacturers with transparent supply chains contribute to a more sustainable and responsible industry.

Pricing and Cost Factors

Understanding the pricing dynamics and cost factors associated with sandwich panels is crucial for making informed decisions aligned with your project budget and goals. Here’s a detailed exploration of the key elements influencing the pricing of sandwich panels:

1. Panel Thickness

The thickness of sandwich panels is a significant determinant of cost. Thicker panels generally offer higher insulation properties and structural strength, but they also come at a higher cost. Assess your project’s insulation requirements and structural needs to strike a balance between performance and budget.

2. Material Composition

The materials used in sandwich panels impact both their performance and cost. Premium materials, such as high-grade metal skins and advanced insulating cores, contribute to superior durability and thermal efficiency but may escalate the overall cost. Consider the specific requirements of your project and choose materials that align with your budget without compromising performance.

3. Customization Options

Manufacturers offering a range of customization options may have varying price points based on the level of flexibility provided. Custom finishes, colors, and sizes tailored to your project’s aesthetic and functional requirements can add to the overall cost. Evaluate the necessity of customization against your budget constraints.

4. Project Scale and Volume

The scale and volume of your project influence pricing. Manufacturers may offer volume discounts for large-scale projects, making it economically favorable to buy in bulk. Consider the size of your project and explore whether manufacturers provide cost advantages for larger quantities.

5. Geographical Location

The geographical location of the manufacturing facility and the project site can affect transportation costs. Choosing a manufacturer with a facility close to your project site may reduce shipping expenses. However, it’s essential to balance proximity with the overall cost-effectiveness of the panels.

6. Industry Standards and Certifications

Compliance with industry standards and certifications may contribute to the overall cost of sandwich panels. Manufacturers investing in quality control processes and obtaining relevant certifications demonstrate a commitment to producing reliable products, which may be reflected in the pricing.

7. Market Demand and Supply

Market dynamics, including demand and supply, can influence pricing. High demand for specific panel types or materials may lead to increased prices. It’s advisable to monitor market trends and collaborate with manufacturers who provide transparent pricing structures.

8. Additional Features and Accessories

The inclusion of additional features, such as integrated accessories or advanced construction elements, can impact the overall cost. Assess whether these features are essential for your project or if a more basic configuration meets your requirements while keeping costs in check.

9. Manufacturer Reputation

Established and reputable manufacturers may command a premium for their brand reliability and product quality. While opting for a reputable manufacturer can provide assurance of product performance, it’s essential to weigh this against your budget constraints.

10. Economic Conditions

Macroeconomic factors, such as inflation and currency fluctuations, can influence material costs and, consequently, the pricing of sandwich panels. Stay informed about economic conditions that may impact the overall cost of your project.

Navigating the pricing and cost factors of sandwich panels requires a thoughtful analysis of project requirements, budget considerations, and the specific offerings of manufacturers. By carefully assessing each factor, you can strike the right balance between cost-effectiveness and the quality of panels for your project.

Sustainability in Sandwich Panel Manufacturing

As sustainability becomes a paramount concern in construction, manufacturers are increasingly adopting environmentally friendly practices. From using recycled materials in panel construction to implementing energy-efficient production processes, the industry is making strides towards a greener future.

Challenges in the Industry

While sandwich panels offer numerous benefits, challenges exist, especially with low-quality manufacturers. Substandard materials and poor production processes can compromise the structural integrity of panels, leading to issues such as delamination and reduced insulation efficiency. Thorough research and due diligence are imperative to avoid such pitfalls.

How to Evaluate Manufacturer Credibility

Ensuring the credibility of a sandwich panel manufacturer is crucial for project success. Look for certifications, industry recognition, and case studies showcasing successful projects. A reputable manufacturer will transparently provide information about their processes, certifications, and adherence to industry standards.

Advancements in Sandwich Panel Technology

The field of sandwich panel technology is dynamic, with continuous advancements aimed at improving performance and sustainability. New materials, such as [Material X], offer enhanced insulation properties, contributing to energy efficiency. Additionally, technological innovations in production processes are streamlining panel manufacturing and reducing environmental impact.

Tips for Proper Installation

Investing in high-quality sandwich panels is only part of the equation; proper installation is equally vital. Hiring professionals with experience in handling sandwich panels ensures that the panels perform optimally. Avoiding common installation mistakes, such as improper sealing and fastening, is key to maximizing the longevity of the panels.

Case Studies: Successful Applications

The real test of sandwich panels lies in their application. Several projects across the globe showcase the success of sandwich panels in achieving energy efficiency, cost savings, and aesthetic appeal. From commercial buildings to industrial facilities, the versatility of sandwich panels is evident in projects like [Project A] and [Project B].

Future Trends in Sandwich Panel Manufacturing

The future of sandwich panel manufacturing holds exciting possibilities. Anticipated trends include the use of smart materials that respond to environmental conditions, further advancements in fire-resistant panels, and increased focus on circular economy principles in panel production.

Customer Reviews and Feedback

Before finalizing a decision, consider the experiences of others. Online platforms, forums, and social media provide valuable insights into customer satisfaction. Reading reviews and feedback from those who have used a particular manufacturer’s panels can offer valuable perspectives.

Conclusion

In the realm of construction and manufacturing, the choice of sandwich panel manufacturers is a decision that reverberates through the life of a structure. From ensuring the right materials to evaluating sustainability efforts, every aspect plays a crucial role. By making informed choices based on thorough research, one can contribute to the creation of enduring and efficient structures.

FAQs

What makes sandwich panels a popular choice?

Sandwich panels are favored for their lightweight yet robust construction, excellent thermal insulation properties, and versatility in various applications.

How do I choose the right thickness for my project?

The thickness of sandwich panels depends on factors such as the desired insulation level, structural requirements, and project specifications. Consult with manufacturers for tailored advice.

Are sandwich panels suitable for residential construction?

Yes, sandwich panels are increasingly being used in residential construction for their energy efficiency, quick installation, and aesthetic appeal.

Can I customize the color and finish of sandwich panels?

Many manufacturers offer customization options, allowing you to choose the color and finish that aligns with your project’s aesthetic requirements.

What maintenance is required for sandwich panels?

Maintenance requirements are minimal. Regular inspections for any signs of damage, such as cracks or leaks, are advisable. Cleaning with mild detergents may be necessary in certain environments.