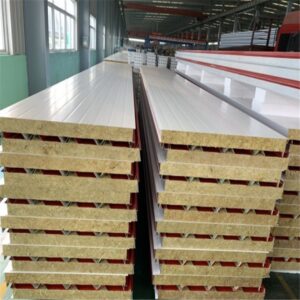

For buildings that need to be constructed with excellent fire, sound, and thermal resistance, mineral wool thermal insulating panels are the perfect choice.

The thicknesses of the sheets range from 0.5 to 0.8 mm. The density of the mineral wool is between 80–140 kg/m3.

When pressed into rolls and sheets, the individual fibers’ exceptional heat conductivity is matched by their superior sound absorption and insulation qualities due to their ability to divide air. Although they are not impervious to the effects of a sufficiently hot fire, materials such as fiberglass, stone wool, and ceramic fibers are frequently used in construction when passive fire protection is needed. These materials are used as spray fireproofing, in stud cavities in drywall assemblies, and as packing materials in firestops.

It can also be used in resin-bonded panels, brake pads, automotive plastics, filler in gasket compounds, filtering media, and hydroponic growing media.

The process of producing mineral fibers is the same; no binder is used. For its reinforcing properties, the fiber itself is utilized as a raw material in many different applications, including coatings, plastics, gaskets, and friction materials.

| Brand of steel plates | Bao Steel, Yieh Phui Steel, Ma Steel, BHP Steel. |

| Painting of steel plates | PVDF, SMP, HDP, PE; The top painting should be above 25μm. |

| Galvanized layer of steel plates | Exterior plate:55% Aluzinc above 100g/m³or Zinc coating above 150g/m³; Inner plate:55% Aluzinc above 70g/m³or Zinc coating above 100g/m³. |

| Thickness of steel plates | 0.14mm-0.6mm. |

| Thickness of core | 50mm/75mm/100mm/120mm/150mm. |

| Density of core | 90/100/120kg/m³ |

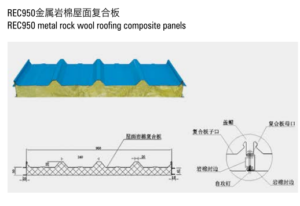

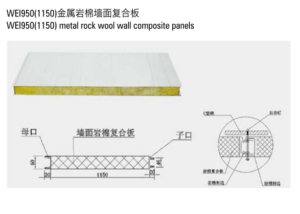

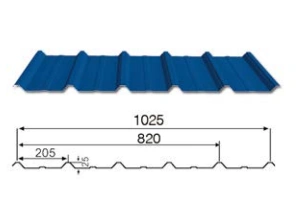

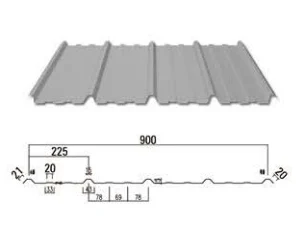

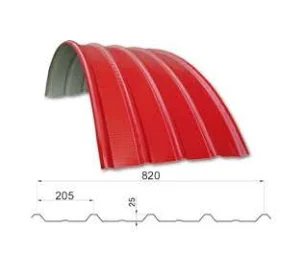

| Effective width | 950/1150mm |

| Panel Length | According to customers’ request |

Performance:

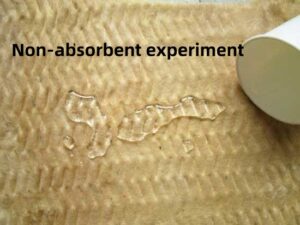

Experiment pictures:

| Rock wool Specification | |

| Material Category | Inorganic insulation material |

| Combustion Performance | A |

| Heat Conductivity Coefficient | 0.04~0.055 w/m·k |

| Density | ≤150kg/m3 |

| Temperature Endurance | 800ºC |

| Water Absorption | >200% |

1.What is Rockwool sandwich panel?

The fireproof rock wool sandwich panel is made of two layers of color-coated steel plates or other metal plates. The rock wool is bonded with the metal panel to form beautiful, flat, rigid, and tough building panels.

2.How thick are Rockwool sandwich panels?

Our thickness for rockwool is 50, 75, 80, 100, 150, 200mm,and density range is 80 – 150 KG/M³.

3. How many kg is Rockwool insulation?

Rockwool refers to a type of thermal insulation made from actual rocks and minerals. A wide range of products can be made from this. material because of its superior ability to block heat and sound.

Wise Link’s main products include clean room panels, clean room Aluminum frame/steel frame doors, clean room double glass windows, clean room dynamic pass boxes, FFU, clean room LED light, and so on.