In the fast-paced world of construction and design, the use of innovative materials is essential to meet the demands of modern architecture. Sandwich panels have emerged as a versatile and practical solution for various applications.

In this article, we’ll delve into the types of sandwich panels, exploring their types, applications, and the numerous benefits they bring to the construction industry.

Sandwich panels, often referred to as composite panels, are a crucial element in the construction and design industry. They offer a unique combination of strength, insulation, and versatility, making them a popular choice for architects and builders alike.

What Are Sandwich Panels?

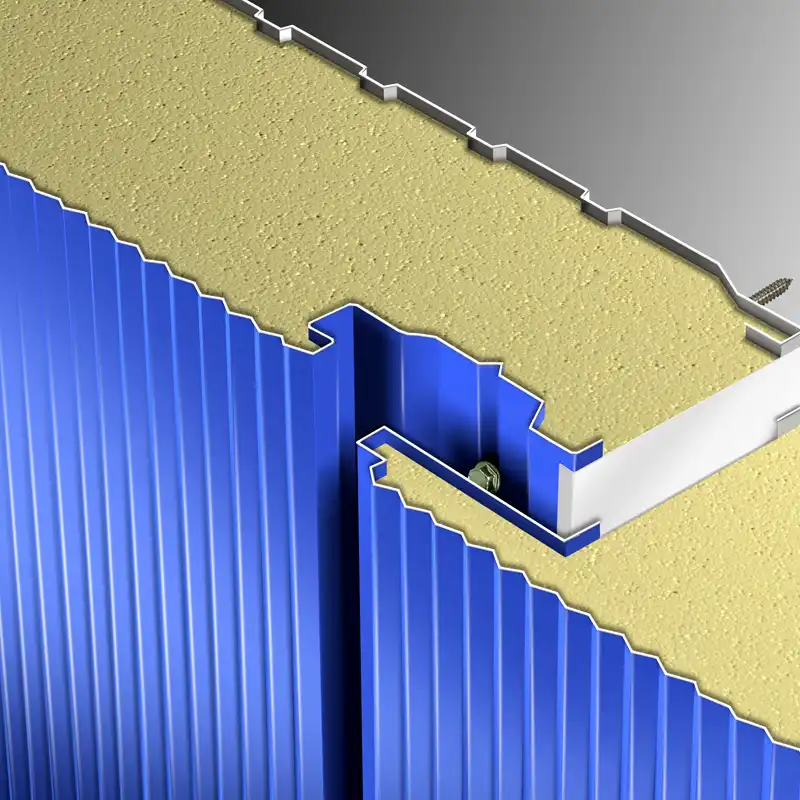

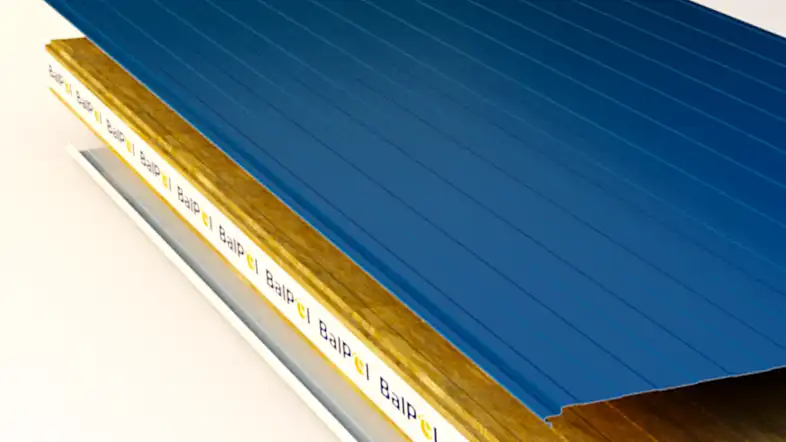

Sandwich panels consist of three layers – a core material sandwiched between two outer layers. These layers can be made from a variety of materials, each offering distinct advantages. The core material, which is usually lightweight, provides insulation and structural support.

Types of Sandwich Panels

Polyurethane (PU) Sandwich Panels

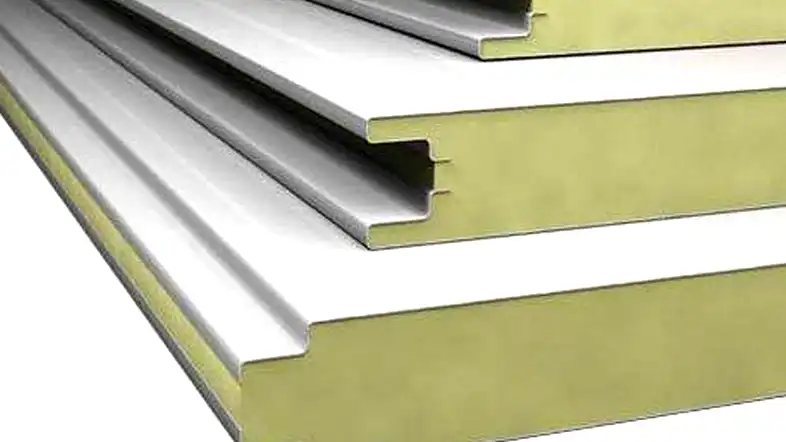

Polyurethane (PU) sandwich panels are a type of composite building material widely used in construction due to their remarkable properties. These panels consist of three layers – two outer layers, typically made of metal or other durable materials, and a core layer made of polyurethane foam. Let’s delve deeper into what makes Polyurethane (PU) sandwich panels a popular choice in the construction industry.

Structure of Polyurethane (PU) Sandwich Panels

- Outer Layers: These layers are typically made of steel, aluminum, or other metals. They provide protection from external elements and contribute to the panel’s structural integrity.

- Core Layer: The core layer is where the magic happens. It consists of polyurethane foam, which is renowned for its exceptional insulation properties. This foam core is responsible for providing thermal and acoustic insulation to buildings.

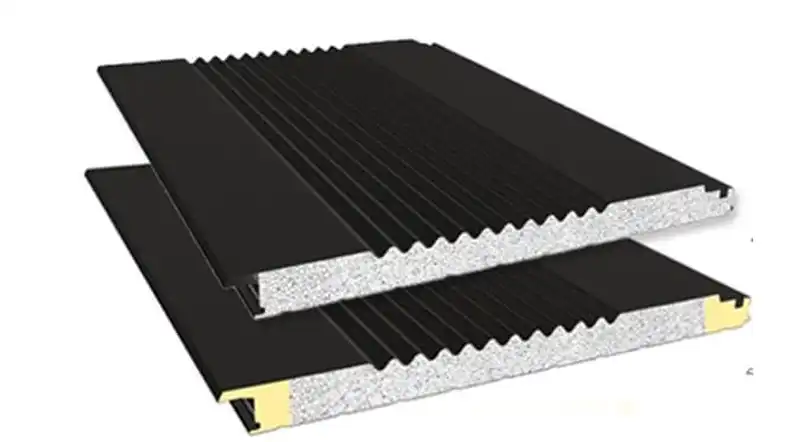

Polystyrene (EPS) Sandwich Panels

Polystyrene (EPS) sandwich panels are a type of construction material widely used in the building industry for various applications. These panels consist of a core made from expanded polystyrene (EPS) foam sandwiched between two outer layers, typically made of steel or aluminum sheets. The combination of these materials creates a lightweight yet sturdy building component with excellent insulating properties.

Let’s explore the key characteristics and uses of EPS sandwich panels in more detail:

Core Material – Expanded Polystyrene (EPS):

EPS Foam: The core of EPS sandwich panels is made of expanded polystyrene foam, which is a lightweight, rigid, and thermally efficient material. It is produced by expanding polystyrene beads with steam, creating a closed-cell structure with low thermal conductivity.

Insulation: EPS foam provides excellent thermal insulation properties, helping to regulate temperature and reduce energy consumption in buildings. It is known for its high resistance to heat flow, making it an ideal choice for maintaining comfortable indoor temperatures.

Outer Layers:

Metal Sheets: The outer layers of EPS sandwich panels are typically made of steel or aluminum sheets. These sheets provide structural strength to the panel while protecting the EPS core from damage and environmental factors.

Variety of Finishes: These metal sheets can have various finishes, such as painted, galvanized, or coated, to enhance durability and aesthetics.

Advantages of EPS Sandwich Panels:

Lightweight: EPS sandwich panels are lightweight, making them easy to handle and transport during construction.

Thermal Insulation: They offer excellent thermal insulation, reducing heating and cooling costs in buildings.

Quick Installation: The panels are prefabricated, allowing for quick and efficient installation, which can save time and labor costs.

Versatility: EPS sandwich panels are versatile and can be used for various applications, including roofing, wall cladding, flooring, and partition walls.

Weather Resistance: The metal outer layers provide protection against weather elements, enhancing the durability of the panels.

Common Applications:

Roofing: EPS sandwich panels are often used as roofing material for commercial and industrial buildings. Their insulating properties help regulate indoor temperatures and reduce energy expenses.

Wall Cladding: They are used as exterior wall cladding systems, providing both insulation and aesthetic value to structures.

Cold Storage: EPS sandwich panels are suitable for constructing cold storage facilities, as they help maintain consistent temperatures.

Partition Walls: In interior construction, these panels are used for creating partition walls and dividing spaces efficiently.

Environmental Considerations:

Recyclability: EPS foam is recyclable, which can help reduce environmental impact. Proper disposal and recycling practices should be followed.

Energy Efficiency: The thermal insulation properties of EPS sandwich panels contribute to energy-efficient building designs, reducing greenhouse gas emissions.

In summary, Polystyrene (EPS) sandwich panels are a versatile building material known for their thermal insulation properties, lightweight nature, and ease of installation. They are commonly used in various construction applications to enhance energy efficiency, structural integrity, and overall building performance.

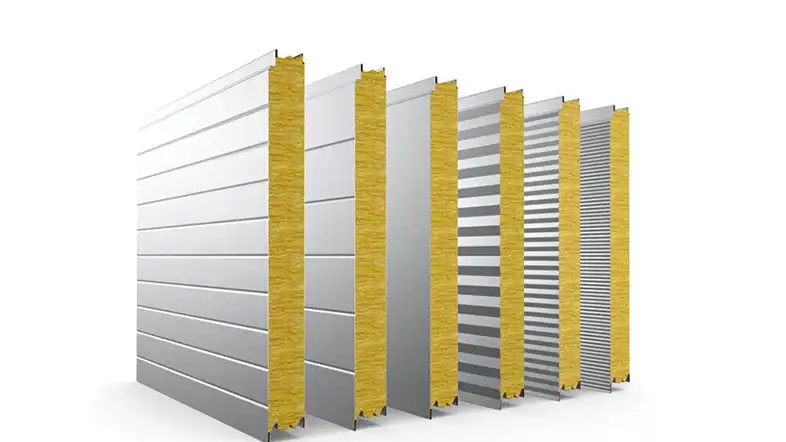

Mineral Wool Sandwich Panels

Mineral wool sandwich panels are fire-resistant and offer excellent acoustic insulation. They are often used in buildings where fire safety is a top priority.

Sandwich Panel Applications

Residential Construction

Sandwich panels are increasingly being used in residential projects for their energy-saving qualities and ease of installation. They help homeowners reduce heating and cooling costs.

Commercial Buildings

Commercial buildings benefit from sandwich panels’ quick installation, which minimizes disruption to business operations. The insulation properties also contribute to a comfortable indoor environment.

Cold Storage Facilities

Sandwich panels are ideal for cold storage facilities, maintaining low temperatures efficiently. Their insulation prevents temperature fluctuations and energy wastage.

Advantages of Using Sandwich Panels

Energy Efficiency

The insulation in sandwich panels reduces energy consumption, making them environmentally friendly and cost-effective.

Excellent Insulation Properties

Sandwich panels provide superior thermal and acoustic insulation, creating comfortable and quiet indoor spaces.

Quick and Cost-Effective Installation

Their modular design allows for swift installation, reducing labor costs and project timelines.

Structural Strength

Despite their lightweight nature, sandwich panels offer impressive structural integrity, contributing to the stability of buildings.

Environmental Considerations

Sandwich panels are sustainable options, with many manufacturers using eco-friendly materials and recycling processes.

Maintenance and Durability

Regular maintenance ensures the long lifespan of sandwich panels, making them a durable choice for various applications.

Future Trends in Sandwich Panel Technology

As technology advances, sandwich panels are likely to become even more energy-efficient and customizable, further revolutionizing the construction industry.

Conclusion

In conclusion, sandwich panels have become indispensable in modern construction due to their versatility, energy efficiency, and ease of installation. They continue to shape the way we build and design structures for a sustainable and comfortable future.

FAQs

Are sandwich panels suitable for extreme weather conditions?

Yes, sandwich panels are designed to withstand a wide range of weather conditions, from extreme cold to scorching heat.

Can sandwich panels be used for interior applications?

Absolutely! Sandwich panels are not limited to exterior use; they are also suitable for interior partitions and ceilings.

Are sandwich panels fire-resistant?

Some types of sandwich panels, such as mineral wool panels, offer excellent fire resistance.

How do sandwich panels contribute to energy savings?

Sandwich panels reduce heating and cooling costs by providing effective insulation, thus lowering energy consumption.

Can sandwich panels be recycled?

Yes, many sandwich panel manufacturers use recyclable materials and promote responsible disposal practices.