Insulated sandwich panels have revolutionized the construction industry with their efficiency, cost-effectiveness, and sustainability.

In this article, we will delve deep into the world of insulated sandwich panels, exploring their types, advantages, applications, working principles, and much more. If you’re planning a construction project or simply curious about this innovative building material, you’ve come to the right place.

What Are Insulated Sandwich Panels?

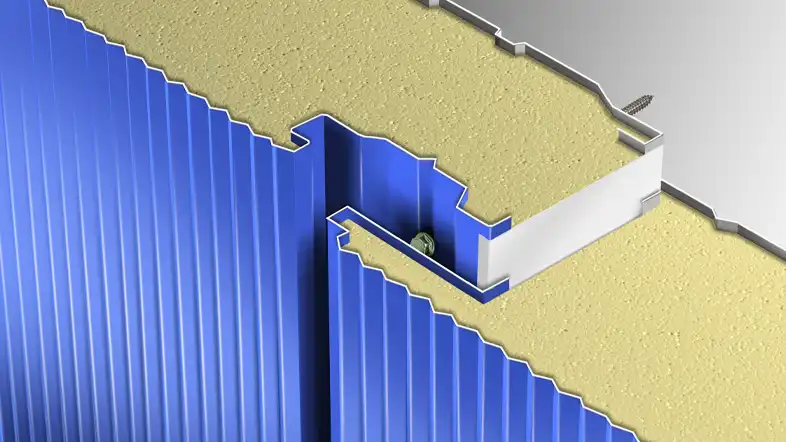

Insulated sandwich panel, often referred to as SIPs (Structural Insulated Panels), are composite building materials consisting of three main layers.

The core layer, typically made of insulating material like foam, is sandwiched between two outer layers, usually composed of metal, wood, or other materials. The result is a strong, durable, and thermally efficient panel used for walls, roofs, and floors in various construction projects.

Types of Insulated Sandwich Panels

Insulated sandwich panels come in various types, each offering distinct advantages and suitability for different applications. These types are primarily categorized based on the core material and the composition of the outer layers. Here are some of the most common types:

Expanded Polystyrene (EPS) Core Panels:

EPS core panels are known for their excellent insulation properties. The core is made of expanded polystyrene, a lightweight and highly insulating material. These panels are cost-effective and provide good thermal performance. They are often used in applications where energy efficiency is a top priority.

Polyurethane (PU) Core Panels:

PU core panels are highly regarded for their exceptional insulation and fire-resistant properties. The polyurethane core offers excellent thermal efficiency, making these panels ideal for cold storage facilities, refrigerated spaces, and structures where fire safety is crucial.

Polyisocyanurate (PIR) Core Panels:

PIR core panels are similar to PU core panels but with improved fire resistance and higher thermal performance. They are often chosen for projects requiring enhanced insulation and fire protection, such as food processing plants and industrial buildings.

Mineral Wool Core Panels:

Mineral wool core panels are valued for their fire resistance and soundproofing capabilities. The core consists of mineral fibers, providing not only excellent insulation but also effective acoustic performance. They are commonly used in applications where fire safety and noise control are essential, such as commercial buildings and apartments.

Composite and Custom Core Panels:

In addition to the core types mentioned above, there are custom variations and composite core panels that combine different materials to meet specific project requirements. These panels can be tailored to provide unique features, such as increased strength or specialized insulation characteristics.

Each type of insulated sandwich panel has its unique advantages and may be better suited to particular construction needs. It’s crucial to consider factors like the intended use, climate conditions, and budget when choosing the right type for your project. Consulting with a construction professional can help ensure you make the best selection for your specific requirements.

Advantages of Using Insulated Sandwich Panels

Insulated sandwich panels offer a multitude of advantages that make them a popular choice in construction and building projects. These advantages include:

Energy Efficiency

Insulated sandwich panels are exceptional insulators, effectively preventing heat transfer. This property results in several energy-related benefits:

- Reduced Energy Consumption: The superior insulation provided by these panels helps maintain stable indoor temperatures, reducing the need for heating and cooling. This, in turn, leads to lower energy consumption and reduced utility costs.

- Environmental Impact: Lower energy use contributes to a reduced carbon footprint, making insulated panels an environmentally friendly choice.

Quick Installation

The modular design of insulated sandwich panels allows for efficient and speedy installation:

- Time Savings: The ease of installation can significantly shorten construction timelines, making projects more cost-effective.

- Minimal Labor Costs: The simplicity of assembly often requires fewer labor hours, leading to cost savings.

Durability

Insulated sandwich panels are known for their long-lasting performance:

- Extended Lifespan: These panels can have a lifespan of up to 50 years or more, ensuring long-term reliability.

- Resistance to Environmental Factors: They are resistant to moisture, pests, and decay, ensuring they remain in excellent condition even in challenging environmental conditions.

Versatility

These panels are highly versatile and adaptable to various applications:

- Use Across Industries: They find applications in a wide range of industries, including residential, commercial, industrial, and agricultural construction.

- Customization: Insulated panels can be tailored to meet specific project requirements, allowing for customization in design and performance.

Cost-Effectiveness

While the initial cost of insulated sandwich panels may be slightly higher than traditional building materials, the long-term benefits often outweigh the upfront investment:

- Energy Savings: Reduced energy costs over the life of the building make insulated panels a cost-effective choice in the long run.

- Lower Maintenance Costs: Minimal maintenance is required, resulting in fewer ongoing expenses.

Fire Resistance

Certain types of insulated sandwich panels can be designed with fire-resistant properties, enhancing safety in specific applications:

- Enhanced Fire Safety: Panels with fire-resistant attributes are suitable for use in areas where fire safety is a concern, such as commercial kitchens or industrial facilities.

- Compliance with Regulations: Meeting fire safety standards and regulations is crucial in many building projects, and insulated panels can help achieve this compliance.

These advantages collectively make insulated sandwich panels an attractive option for modern construction projects. Whether you’re focused on energy efficiency, cost savings, durability, or specific safety requirements, these panels offer a well-rounded solution for a variety of construction needs.

Applications of Insulated Sandwich Panels

Applications of Insulated Sandwich Panels

Insulated sandwich panels are incredibly versatile and find applications in various industries and construction projects. Their exceptional thermal efficiency, durability, and ease of installation make them a popular choice for a wide range of uses. Here are some of the key applications of insulated sandwich panels:

Residential Construction:

- Insulated sandwich panels are increasingly being used in residential construction for walls, roofs, and floors. They provide excellent insulation, helping homeowners reduce energy consumption and costs while maintaining comfortable indoor temperatures.

Commercial Buildings:

- Commercial structures, such as offices, retail stores, and warehouses, benefit from insulated sandwich panels. These panels contribute to energy-efficient buildings, reducing heating and cooling expenses.

Cold Storage Facilities:

- Insulated sandwich panels are ideal for cold storage warehouses and refrigerated spaces. Their ability to maintain consistent temperatures makes them crucial in preserving perishable goods.

Industrial Facilities:

- Factories and industrial buildings utilize insulated sandwich panels for both exterior and interior walls. They provide a controlled environment, essential for certain manufacturing processes.

Cleanrooms:

- In industries like pharmaceuticals, electronics, and aerospace, cleanrooms are necessary. Insulated panels help maintain the stringent environmental conditions required for cleanroom operations.

Agricultural Buildings:

- Farm structures, including barns and poultry houses, often use insulated sandwich panels to regulate temperature and provide a comfortable environment for animals and crops.

Educational Institutions:

- Schools and universities may opt for insulated panels in new construction or renovations to enhance energy efficiency and create comfortable learning environments.

Healthcare Facilities:

- Hospitals and healthcare facilities rely on insulated sandwich panels to ensure temperature control and a sterile environment for patient care.

Food Processing Plants:

- Food processing facilities benefit from insulated panels’ ability to maintain specific temperatures required for food safety and production.

Data Centers:

- Data centers require precise temperature and humidity control. Insulated sandwich panels help create the controlled environment needed to protect sensitive computer equipment.

Prefab Housing:

- Prefabricated or modular housing often incorporates insulated panels for quick and energy-efficient construction.

Sports Facilities:

- Indoor sports arenas and gyms use insulated panels for their insulation properties and to maintain comfortable playing conditions.

Retail Stores:

- Retailers looking to reduce operational costs utilize insulated panels for their stores, benefiting from both energy efficiency and a comfortable shopping environment.

Transportation:

- Insulated panels are also used in the construction of transportation-related infrastructure, such as train stations and airports.

Renovations and Retrofits:

- Existing buildings can be retrofitted with insulated sandwich panels to improve insulation, energy efficiency, and overall building performance.

These examples demonstrate the broad range of applications for insulated sandwich panels across different industries. Their adaptability and energy-efficient properties continue to make them a popular choice in modern construction and building projects.

How Insulated Sandwich Panels Work

Insulated sandwich panels work on a simple yet highly effective principle, which makes them an exceptional choice for maintaining comfortable indoor environments. These panels consist of three main layers: two outer layers, often composed of metal, wood, or other materials, and a core layer, typically made of insulating material. Here’s how the components work together to provide efficient insulation:

The Core Insulation

The core layer of insulated sandwich panels is the key to their thermal performance. Common core materials include Expanded Polystyrene (EPS), Polyurethane (PU), Polyisocyanurate (PIR), or mineral wool. Each of these materials has excellent insulating properties, which helps maintain the desired indoor temperature.

Preventing Heat Transfer

The core layer acts as a barrier to heat transfer, preventing the flow of thermal energy from one side of the panel to the other. In cold weather, the core material resists the loss of heat from the interior of a building to the exterior. Conversely, in hot weather, it prevents heat from penetrating the building’s interior.

Air Tightness

Insulated sandwich panels are designed to be airtight, meaning they do not allow air to pass through easily. This characteristic prevents drafts and helps maintain a consistent indoor temperature.

Continuous Insulation

The core layer provides continuous insulation across the entire surface of the panel, ensuring there are no gaps or weak points that could compromise thermal performance.

Rigidity and Strength

The outer layers of the panel, typically made of metal or other durable materials, provide rigidity and structural strength to the panel. This allows the panels to function not only as insulators but also as load-bearing elements in construction.

Ease of Installation

The modular design of insulated sandwich panels simplifies the construction process. They are manufactured to fit specific dimensions, ensuring a tight and secure fit during installation. This ease of installation results in time and labor savings for construction projects.

Moisture Resistance

In addition to their insulation properties, insulated sandwich panels are often designed to be resistant to moisture. This quality is essential for ensuring the panels maintain their insulation capabilities and structural integrity over time.

In summary, insulated sandwich panels work by utilizing the insulating properties of their core material to prevent the transfer of heat between the interior and exterior of a building. This creates a comfortable and energy-efficient indoor environment. Their modular design, ease of installation, and durability make them a practical choice for various construction applications, providing both thermal efficiency and structural integrity.

Choosing the Right Insulated Sandwich Panel

Selecting the appropriate insulated sandwich panel is crucial to ensuring the success of your construction project. The right choice will depend on various factors, including the intended use, local climate conditions, and budget constraints. Here’s a guide to help you make an informed decision:

1. Intended Use:

- Consider the specific purpose of the panel. Are you using it for walls, roofs, or floors? The requirements for each application can vary, so choose a panel that aligns with your project’s needs.

2. Climate Conditions:

- The local climate plays a significant role in selecting the right panel. For colder regions, panels with high thermal insulation properties, such as Polyurethane (PU) or Polyisocyanurate (PIR) core panels, are often preferred. In warmer climates, panels that provide good thermal resistance and minimize heat gain may be more suitable.

3. Fire Safety:

- Depending on your project’s requirements and local building codes, you may need fire-resistant insulated panels. Some panels are specifically designed to meet stringent fire safety standards, making them ideal for applications where fire resistance is a priority.

4. Structural Considerations:

- Take into account the load-bearing requirements of your project. Insulated sandwich panels can serve as both insulators and load-bearing elements, but the thickness and core material will impact their structural capabilities.

5. Budget Constraints:

- Cost is a significant consideration. While insulated sandwich panels may have a higher upfront cost than traditional building materials, they often lead to long-term cost savings due to their energy efficiency. Consider your budget and the potential return on investment over time.

6. Consult a Professional:

- When in doubt, consult with an architect or engineer who specializes in construction. They can provide valuable insights and recommend the most suitable panel for your specific project.

7. Consider Customization:

- In some cases, you might need custom insulated sandwich panels with unique features. Manufacturers can often tailor panels to meet specific project requirements, including thickness, insulation type, and outer layer materials.

8. Environmental Impact:

- If sustainability is a concern, consider the environmental impact of the materials. Some panels are made from recyclable materials and can contribute to a building’s eco-friendliness.

9. Warranty and Quality:

- Review the warranties offered by panel manufacturers and ensure you choose a product from a reputable company. Quality and longevity are essential factors in the decision-making process.

By carefully evaluating these factors, you can make an informed choice when selecting the right insulated sandwich panel for your project. Consulting with professionals and thoroughly researching the available options will help you find the ideal solution that aligns with your project’s goals and requirements.

Installation Process

The installation of insulated sandwich panels is relatively straightforward, and it can be done by experienced construction teams. Precise measurements and careful handling are crucial to ensure a tight fit and maximum insulation.

Maintenance and Durability

Regular maintenance is minimal. These panels are resistant to moisture, decay, and pests, ensuring they remain in excellent condition for years.

Cost Considerations

While the initial cost may be higher than traditional building materials, the long-term energy savings and durability of insulated sandwich panels make them a cost-effective choice.

Environmental Impact

Insulated sandwich panels are eco-friendly due to their energy-efficient properties and recyclability. They help reduce a building’s carbon footprint.

Innovations in Insulated Sandwich Panels

Ongoing research and development continue to improve the performance and versatility of insulated sandwich panels, making them even more attractive for modern construction.

Case Studies: Real-World Applications

Explore real-world examples of how insulated sandwich panels have been used in various construction projects, showcasing their benefits in action.

Frequently Asked Questions

Are insulated sandwich panels fire-resistant?

Insulated sandwich panels can be designed to have fire-resistant properties, making them suitable for use in fire-prone areas.

What is the maximum span for insulated sandwich panels?

The span depends on factors like panel thickness and load. Consult with an engineer for specific project requirements.

Can insulated sandwich panels be used in residential construction?

Yes, these panels are suitable for both residential and commercial construction.

Do insulated sandwich panels require a vapor barrier?

In most cases, a vapor barrier is not necessary, as the panels themselves provide an effective moisture barrier.

Can insulated sandwich panels be recycled?

Yes, many components of insulated sandwich panels are recyclable, reducing their environmental impact.

Conclusion

Insulated sandwich panels are a game-changer in the construction industry, offering a winning combination of energy efficiency, durability, and versatility. By making an informed choice, you can enhance your construction projects and contribute to a more sustainable future.