The Role of Smart Technologies in Revolutionising Cleanroom Efficiency

Cleanrooms play a critical role in industries requiring stringent contamination control, such as pharmaceuticals, biotechnology, electronics, and medical devices. Achieving the highest standards of cleanliness and efficiency is essential for these environments, but doing so has traditionally required high levels of energy and resources. Smart technologies, including energy-efficient HVAC systems and real-time monitoring tools, are now revolutionizing cleanroom efficiency, reducing energy consumption, and improving contamination control. With the integration of Internet of Things (IoT) sensors, data analytics, automated controls, and predictive maintenance, smart technologies are setting a new standard for cleanroom performance.

Wise Link specializes in providing advanced cleanroom solutions that incorporate smart technologies and energy-efficient HVAC systems. This guide explores how these innovations are transforming cleanroom efficiency, from reducing operational costs to supporting sustainability goals, and provides insight into Wise Link’s approach to designing smart, high-performance cleanrooms.

1. Understanding the Role of Smart Technologies in Cleanrooms

Smart technologies in cleanrooms refer to systems and tools that use data, automation, and advanced controls to optimize performance. By using IoT sensors, real-time monitoring, and data analytics, these technologies provide actionable insights that help maintain cleanliness standards while minimizing energy consumption and operational costs.

Key Benefits of Smart Cleanroom Technologies:

- Enhanced Contamination Control: Automated systems detect contaminants and respond in real time, ensuring consistent air quality and reducing human error.

- Energy Efficiency: Smart technologies optimize resource usage, reducing the demand for energy-intensive components like HVAC systems.

- Improved Maintenance and Longevity: Predictive maintenance enabled by smart technologies prevents equipment failure, reducing downtime and extending the lifespan of critical systems.

Wise Link’s Smart Cleanroom Solutions: We integrate smart technologies to provide clients with intelligent cleanroom solutions that enhance efficiency, reduce waste, and support regulatory compliance.

2. Energy-Efficient HVAC Systems and Real-Time Monitoring

The HVAC system in a cleanroom is responsible for maintaining air quality, temperature, humidity, and pressure, making it one of the most energy-intensive components. Energy-efficient HVAC systems equipped with smart controls and real-time monitoring tools can significantly reduce energy consumption while maintaining the desired environment.

Advanced HVAC Controls

Smart HVAC systems use variable air volume (VAV) and energy recovery ventilation (ERV) technologies to adjust airflow, temperature, and humidity based on real-time needs. This minimizes energy use while maintaining the required ISO cleanliness level.

- VAV Systems: VAV systems adjust the volume of air delivered to the cleanroom based on current contamination levels. This system reduces unnecessary air changes, saving energy while still meeting cleanliness requirements.

- ERV Systems: ERV systems recover energy from exhaust air to pre-condition incoming air, reducing the load on HVAC systems and saving energy.

Wise Link’s HVAC Solutions: We design cleanroom HVAC systems with VAV and ERV technologies, ensuring optimal environmental control with minimal energy waste.

IoT-Enabled Monitoring and Control

Smart HVAC systems use IoT sensors and monitoring tools to gather data on temperature, humidity, pressure, and particle levels. This data is processed and used to adjust HVAC settings automatically, ensuring that conditions remain within the specified range.

- Real-Time Feedback: IoT sensors provide real-time feedback on cleanroom conditions, allowing operators to make adjustments as needed.

- Automated Controls: Automated HVAC controls reduce human intervention and ensure that settings are optimized for both performance and energy efficiency.

Wise Link’s Real-Time Monitoring: Our cleanroom systems include IoT-enabled monitoring that allows clients to oversee and adjust cleanroom conditions in real time, supporting efficient, consistent, and compliant operations.

3. Data Analytics for Predictive Maintenance and Performance Optimization

Data analytics has become an essential tool for managing cleanroom performance. By collecting data on HVAC performance, energy use, and equipment status, predictive analytics identify trends and predict when maintenance is needed. This proactive approach reduces downtime, enhances efficiency, and extends the lifespan of cleanroom equipment.

Benefits of Predictive Maintenance

Predictive maintenance helps cleanroom operators address potential issues before they lead to equipment failure. This not only reduces the cost of repairs but also maintains cleanroom uptime and supports continuous compliance.

- Reduced Downtime: Predictive maintenance identifies potential issues, allowing operators to make adjustments or repairs before a breakdown occurs.

- Extended Equipment Lifespan: By addressing maintenance needs proactively, predictive maintenance extends the life of equipment and reduces replacement costs.

Optimizing Energy Efficiency with Data-Driven Insights

Data analytics can reveal insights into how energy is being used in a cleanroom. By understanding patterns in energy consumption, cleanroom operators can make targeted adjustments to reduce waste and improve efficiency.

Wise Link’s Predictive Maintenance Solutions: We incorporate predictive maintenance systems into our cleanroom designs, providing clients with tools to monitor equipment health and reduce operational costs through timely maintenance.

4. Automated Controls for Contamination Control and Workflow Efficiency

Automated controls enhance cleanroom performance by reducing contamination risk and streamlining operations. From air quality control to material handling, automated systems improve efficiency by eliminating human error and maintaining consistent environmental conditions.

Automated Air Quality Control

Automated air quality controls use sensors to detect changes in particle levels, adjusting HVAC settings and airflow to ensure that cleanroom air remains uncontaminated.

- Dynamic Airflow Adjustments: Automated systems can increase or decrease airflow based on contamination levels, ensuring that cleanroom air quality remains consistent.

- Contamination Detection: IoT-enabled sensors detect airborne particles and automatically adjust filtration systems to maintain the required cleanliness level.

Automated Material Handling and Workflow Management

Automated material handling systems reduce human traffic within the cleanroom, minimizing contamination risks. These systems transport materials, equipment, and products within the cleanroom without requiring manual intervention.

Wise Link’s Automation Solutions: We offer cleanroom designs that integrate automated air quality controls and material handling systems, supporting both contamination control and operational efficiency.

5. Sustainable Practices and Energy Conservation

Sustainability is increasingly important in cleanroom operations, and smart technologies offer new ways to conserve energy and reduce waste. Energy-efficient HVAC systems, automated lighting controls, and sustainable materials support a zero-carbon approach to cleanroom design.

Automated Lighting Controls

Automated lighting systems adjust light levels based on occupancy and natural light availability, ensuring that lights are only used when necessary. LED lighting combined with motion sensors or daylight harvesting systems provides significant energy savings.

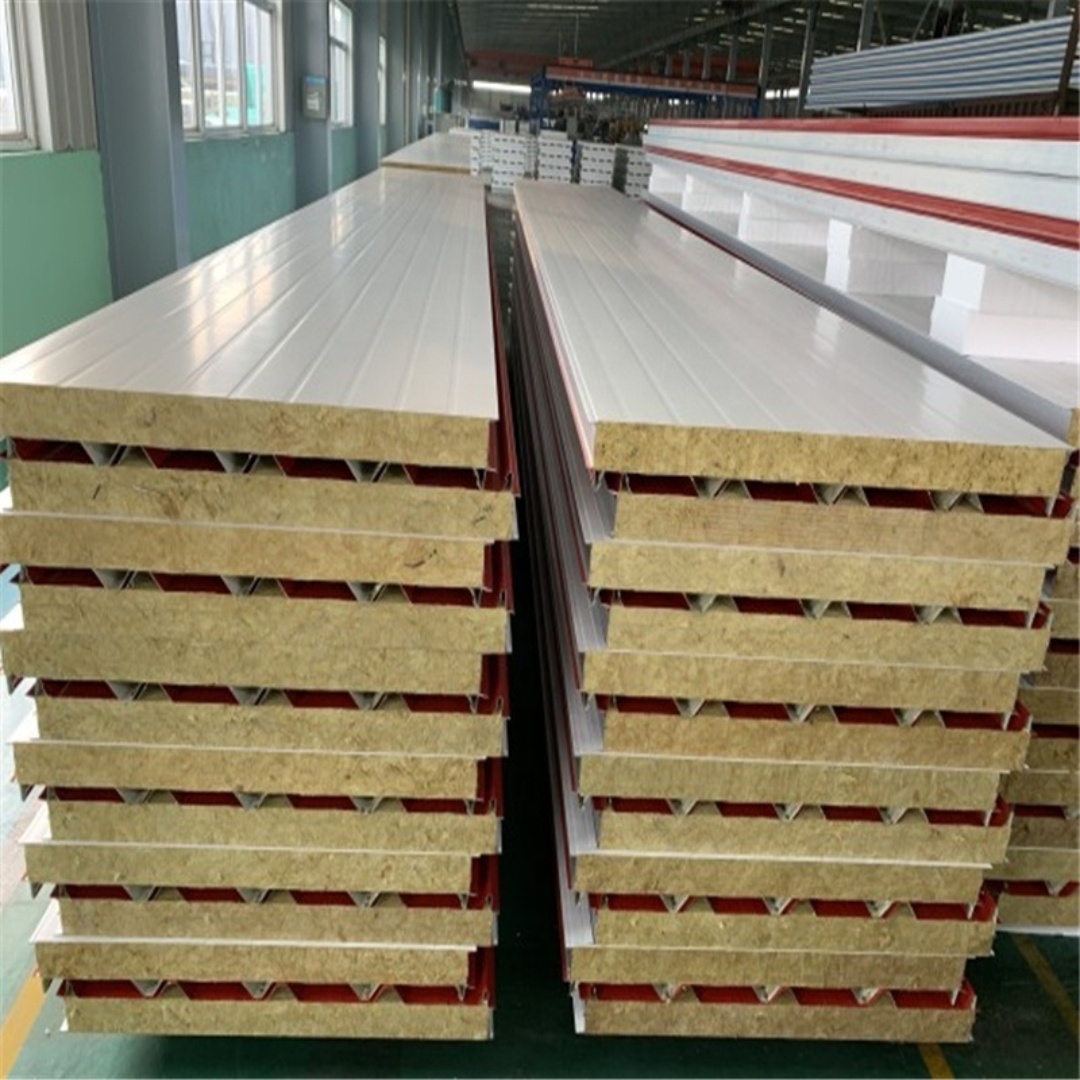

Eco-Friendly Building Materials

Sustainable building materials, such as low-VOC panels and recyclable components, reduce the environmental impact of cleanroom construction. These materials contribute to sustainable operations without compromising cleanliness or compliance.

Wise Link’s Sustainable Solutions: Our cleanroom designs incorporate energy-efficient lighting, eco-friendly materials, and automated controls to reduce environmental impact and support sustainable practices.

Conclusion: Revolutionizing Cleanroom Efficiency with Wise Link’s Smart Technologies

Smart technologies are transforming cleanroom efficiency by optimizing energy use, enhancing contamination control, and supporting sustainable operations. From IoT-enabled HVAC systems to predictive maintenance and automated controls, these innovations offer cleanroom operators unprecedented control over environmental conditions and cost management.

At Wise Link, we specialize in delivering cleanroom solutions that integrate the latest in smart technology, providing clients with high-performance, energy-efficient environments that meet the strictest cleanliness standards. If you’re ready to explore how smart technologies can enhance your cleanroom operations, contact Wise Link today to discuss a customized solution that meets your efficiency, sustainability, and compliance goals.