Cleanrooms are essential to any manufacturing process where particulate contamination can affect the quality of goods produced.

Specific clean room classifications and ISO class code descriptions provide protective guidelines and secure environments

through controlled air filtration, which lowers the possibility of product contamination or large particulate interference within

critical process manufacturing. Specific cleanroom requirements and ISO 14644-1 cleanroom standards are used to protect

consumers from any potential flaw or mishandling of a product.

A clean room is an area where people can work once the air quality exceeds a certain standard. Its job is to manage particulate pollution, or dust particles. to fulfill the demands of conducting scientific experiments and producing precision goods. The term “clean” room does not fully describe what a clean room is; rather, it refers to a collection of building decorations (closed decorations with a relatively isolated atmosphere), purification of air conditioning, pure water, pure gas, power electricity, lighting electricity, process pipeline, and other professional and technical products. Various industries and departments have significant requirements for temperature, temperature, lighting, noise, static electricity, micro-vibration multi-functional comprehensive whole.

|

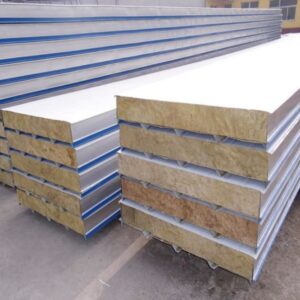

Wall Panel

|

Thickness – 50mm, double color painted hot-dipping galvanized steel sheet, 0.5mm thick PE coated steel sheet, 0,8mm thick GI

frame, infill with rock wool, comply with accessories below in item Height: 2600mm. |

|

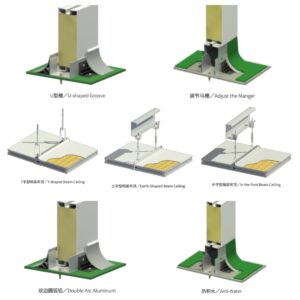

Wall Panel accessories

|

Aluminum joint profiles

|

|

Top track (aluminum slot), 30*50*30mm

|

|

|

Adjustable floor track

|

|

|

Straight corners

|

|

|

R50 round corner inside

|

|

|

3-way connector inside (per pc)

|

|

|

middle type 3-way connector outside

|

|

|

door seal (per pair)

|

|

|

Ceiling panels

|

Thickness – 50mm, double layer color painted hot-dipping galvanized steel sheet, 0.5mm thick PE coated steel sheet, 0.8mm thick GI

frame, infill with rock wool, with single glass magnesium oxide boards for reinforcement. |

|

Ceiling Panel accessories

|

Aluminum joint profiles

|

|

Aluminum Grid

|

|

|

Hanging bar, with expansion bolts, T screw, square regulator, connector, nuts

|

|

|

Clean room Doors

|

Steel doors: 50mm thickness; 1.0 mm double-side electro galvanized steel sheet, with paper honeycomb inside; Including 50mm thick

door leaf, 50mm thick steel frame, hinge, GEZE lock, Auto-down bottom seal, with double 5mm tempered glass window (round or rectangular window), not include door closer. |

|

Single leaf, size 1000*2100mm

|

|

|

Double leaf, size 1900*2100mm

|

|

|

Door Closer, Brand: GEZE 1000C

|

|

|

Interlock

|

Electronic interlock to control two or more doors, with electromagnetic lock, light Indicator and main control box

|

|

2 Doors

|

|

|

Windows

|

Double tempered glass view window, joints filled with silicon sealant, with vapor absorption, 5mm thick glass

|

|

Size: 1200*1000*50mm

|

|

|

Size: 1500*1000*50mm

|

|

|

Silicone

|

Dow corning silicone

|

|

PVC conduits

|

PVC conduit (25mm) inside wall panels

|

|

Opening cost

|

Openings in ceiling/wall panels

|

1. It is possible to view core material fire ratings.

2. The aluminum profiles that connect the cleanroom wall panel system enable modular installation, which is quick and easy. Non-standard wall panel systems can be modified.

3. Customization at the factory.

4. A diverse core material that offers fire safety, heat insulation, noise reduction, and moisture resistance in a variety of settings.

5. The factory offers more services to consumers in addition to six different types of steel.

6. The strength, flatness, and at tractiveness of the cleanroom wall panel have all significantly improved, and the product quality has increased.

7. The line pipeline box and the hole reinforcement reservation are pre-assembled into the board’s interior at the manufacturer, which significantly lowers secondary pollution during usage, particularly in the operating room.

|

Clean rank of suspended particles in air of clean room or clean area

|

|||||||

|

ISO rank for air cleanness

|

Bigger or equal to maximum concentration limits in table (P/m3-air)

|

||||||

|

0.1um

|

0.2um

|

0.3um

|

0.5um

|

1um

|

5um

|

American federal 209E rank for cleanness

|

|

|

ISOClass1

|

|

|

|

|

|

|

|

|

ISOClass2

|

100

|

24

|

10

|

4

|

|

|

|

|

ISOClass3

|

1000

|

237

|

102

|

35

|

8

|

|

1

|

|

ISOClass4

|

10000

|

2370

|

1020

|

352

|

83

|

|

10

|

|

ISOClass5

|

100000

|

23700

|

10200

|

3520

|

832

|

29

|

100

|

|

ISOClass6

|

1000000

|

237000

|

102000

|

35200

|

8320

|

293

|

1000

|

|

ISOClass7

|

|

|

|

352000

|

83200

|

2930

|

10000

|

|

ISOClass8

|

|

|

|

3520000

|

832000

|

29300

|

100000

|

|

ISOClass9

|

|

|

|

35200000

|

8320000

|

293000

|

300000

|

1.What is an example of a clean room?

Cleanrooms use HEPA filters to remove particles from the air. It is common to see pharmaceutical cleanrooms, medical device cleanrooms, semiconductor cleanrooms, electronic cleanrooms, aerospace cleanrooms, food cleanrooms, USP797 compounding pharmacy cleanrooms and biotech cleanrooms.

2.What are clean room standards?

Clean rooms are classified according to the cleanliness level of the air inside the controlled environment. The clean room class is the level of cleanliness the room complies with, according to the quantity and size of particles per cubic meters of air.

3.What is the principle of clean room?

To summarize, the principle of mixed flow cleanroom is that when a certain amount of clean air is supplied into the room, it will disperse and mix with the surrounding air, and at the same time the same amount of air is exhausted from the return air grille.

4.What is the difference between operating room and clean room?

Abstract: The operating rooms are known as clean rooms because it must have the high quality air without the dust and the particles. In the clean room, the dust that is sourced from both the personnel and the patient and the machines, causes the risk of infection.

Wise Link’s main products include clean room panels, clean room Aluminum frame/steel frame doors, clean room double glass windows, clean room dynamic pass boxes, FFU, clean room LED light, and so on.