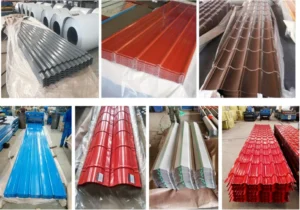

Corrugated metal roofing is a cost-effective option that is popular in commercial, agricultural, and industrial settings. It consists of sheets of metal that are shaped with ridges and valleys, which give it its characteristic wavy appearance. Corrugated metal roofing is lightweight, easy to install, and resistant to fire, wind, and hail.

The corrosion resistance of general color coated roofing sheet is 5-10 years, the color is maintained for 5-10 years, and most color coated roofing sheet are generally used for 10-15 years.

In the absence of corrosive substances, except for human damage, the stability of color coated roofing sheet is relatively good. Generally, the life of color coated roofing sheet is about 20 years.

The service life of most color coated roofing sheet is related to the thickness of the color-coated galvanized layer, the stabilization layer, the paint layer, and the quality of the materials of each layer. While paying attention to the price, we should also pay attention to the quality of the product. The environment and the quality of the color coated roofing sheet will affect the life of the color steel tile.

color coated roofing sheet should pay attention to windproofing. After the construction is completed, look at the connection and reinforcement of each part to ensure these conditions. With the usual attention to maintenance, the life of color steel tiles will be longer.

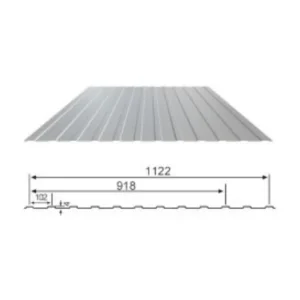

| Thickness | 0.12mm-1.2mm | ||||

| Width | 600-1150mm | ||||

| Length | 1000-12000mm | ||||

| Grade | DX51D+Z DX52D+Z DX53D+Z DX54D+Z DX56D+Z DX57D+Z |

CS A CS B CS C FS A FS B |

SGCC SGCD |

SGC340 SGC400 SGC440 SGC490 SGC510 |

S220GD+Z S250GD+Z S280GD+Z S320GD+Z S350GD+Z S550GD+Z |

| Az/Zn Coating | 30-275gsm | ||||

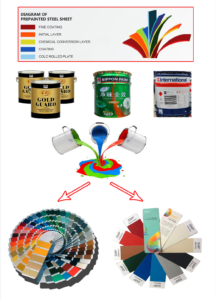

| Color | According to RAL code | ||||

| Coating Types | PE, SMP, JD, HDP, PVDF | ||||

| Coating | Top Paint: 10~25 micron | ||||

| Back Paint: 5~12micron | |||||

| Type of coating process | Front: Double Coated & Double Drying | ||||

| Back: Double Coated & Double Drying, Single Coated & Double Drying |

|||||

| Finish | High light, Glossy, Matte | ||||

| Packing | Standard export package (Plastic film in the first layer, second layer is Kraft paper. Third layer is galvanized sheet+package strip+corner protected, one pallet about 3 tons) | ||||

| Application | Building industry ,structural use, roofing, commercial use ,household appliance, industry facilities, office buildings | ||||

| Advantages | 1.Design according to customers ‘requirements 2.Production under ISO9001-2008 Quality System 3.Easy to be installed as light weight4.Our products are recyclable materials 5.The less construction period, the more using time.6.paint your logo for free |

||||

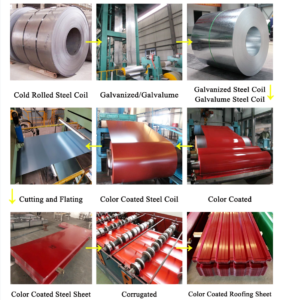

The production process

| Package | 3 layers of packing, inside is kraft paper, water plastic film is in the middle and ouside GI steel sheet to be covered by steel strips with lock, with inner coil sleeve . |

| Remarks | Insurance is all risks and accept the third party test |

| Loading Port | Tianjin/Qingdao/Shanghai Port |

| Material | CGCC,SGCH,G350,G450,G550,DX51D,DX52D,DX53D |

| Thickness | 0.12-1.0mm |

| Width | 750-1250mm(before corrugation) 600-1100mm(after corrugation) |

| Length | 1000-3500mm or as require |

| Coating type | Galvanized, Galvalume, Prepainted coating(PE, SMP, HDP, PVDF) |

| Painting Thickness | Z40-275; AZ30-AZ150; Top: 15 to 25 um (5 um + 12- 20 um) back: 7 +/- 2 um |

| Pallte Weight | 3-5 Tons |

| Annual Output Quantity | 350,000MT |

| MOQ | 25 tons or one container |

| Payment | T/T, LC, Kun Lun Bank, Western Union, Paypal, O/A, DP |

| Hardness | Soft hard(60),medium hard(HRB60-85),full hard(HRB85-95) |

| Surface structure | Matt, PVC film, wood grain, Flower Grained, embossed, etc |

| Color chart | RAL color number |

| Application | exterior and interior wall,roofs,and soffits |

Our colour can be choosed and customized

Wise Link’s main products include clean room panels, clean room Aluminum frame/steel frame doors, clean room double glass windows, clean room dynamic pass boxes, FFU, clean room LED light, and so on.