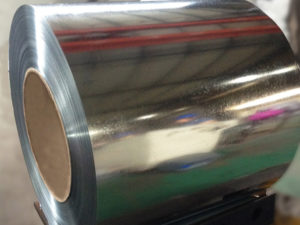

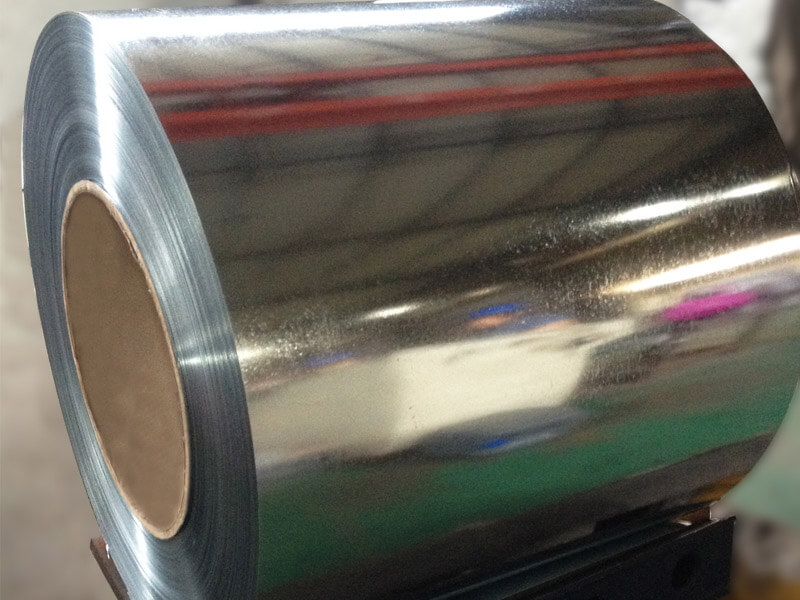

Hot-Dipped Galvanized Steel Coil Manufacturer

Discover our premium Hot-Dipped Galvanized Steel Coils, meticulously crafted to meet the highest standards of performance and durability. Coated with a robust layer of zinc, our galvanized steel coils provide superior corrosion resistance, making them the ideal choice for a wide range of applications across various industries.

Hot-dipped galvanized steel coils undergo a specialized process where the steel coil is immersed in a bath of molten zinc, forming a strong metallurgical bond between the zinc and steel. This protective zinc coating creates a reliable and long-lasting barrier against rust and corrosion, ensuring the longevity of the steel in challenging environments.

Our galvanized steel coils are engineered for exceptional durability, making them a top choice for applications in construction, manufacturing, and other industries that demand high-quality corrosion resistance and long-term performance.