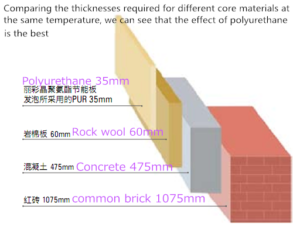

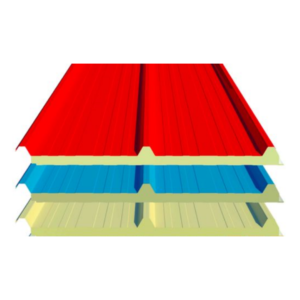

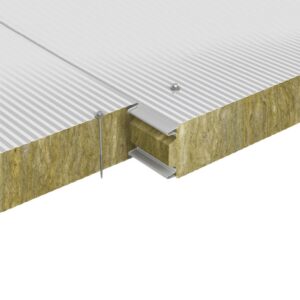

Polyurethane sandwich panels, or PU Sandwich Panels, are made of two layers of colored steel sheets that are resistant to weather and are filled with strong polyurethane between two layers of materials that are fireproof. This material is appropriate for a variety of roofs and walls, including those on large-scale factory buildings, storage facilities, exhibition halls, gymnasiums, freezing stores, purification workshops, and so on. It has the qualities of being weatherproof, heat-resistant, temperature-regulating, and aesthetically pleasing.

It is widely applicable in the petroleum, chemical, building, packaging, refrigeration, military, space, aviation, transportation, and industrial model design industries as a structural and heatproof material.

Definition of PU sandwich panels:

Polyurethane Sandwich Panel also called PU Sandwich Panel,the top & bottom sheet of this panel is Galvanized & Pre-painted steel sheets,and core material is 5 components Polyurethane glue, it is formed by heating, foaming & laminating. Polyurethane is the best material for heat and sound insulation. It can reduce the heat transmission caused by difference in the internal and external temperature, and get to maximum efficiency of freezing and refrigeration systems. It is a new type of heat insulation material for lower construction cost.Panels are in multiple varieties and specifications to meet the need of various sites and projects.

Material introduction:

Usually the surface sheet of PUR or PIR sandwich panels is PPGI or PPGL steel color coated sheets.PPGI is prepainted galvanized coated steel and PPGL is prepainted Al-Zn coated steel.For coating type,you could choose PE, PVDF, HDP, SMP,ect.Our strategic cooperation brands are Bluescope, Bao-steel, Shougang steel, Guanzhou steel, Yieh Phui steel,Xinyu steel,etc.

Panel ribs for your choices:

| Thickness | 50/75/100/120/150/200(mm) |

| Effective width | 950, 980, 1100, 1150(mm) |

| Length | According to customer’ s request, less than 11.8m. |

| Materials | Polystyrene foam board, Color steel sheet |

| Structure | Upper and lower layer: 0.4mm-0.8mm Color steel sheet |

| Middle: Polystyrene foam board | |

| EPS density | 60/80/100/120 kg/m³ |

| Conventional color | White, sea blue, red etc. |

| Lifetime | More than 60 years |

| Performance | Light weight, heat insulation, water resistant, green and environmental |

| Usage | Roof, Wall, Ceiling, Partition |

Metal Polyurethane/PU/PIR/PUR/PUF Sandwich Panels

1. Roofing panel

2. Wall panel

3.Cold room panel

Performance

Packing&Delivery

FAQ

Q1: Do you offer guiding service for installation on site overseas?

A: Yes. We do. We will give detailed installation drawings and video for free. And if you need, we can send guide engineers as installation director even a working team to your construction site.

Q2: How can I get your quick quotation on my project?

A: You can chat with us at anytime via email or phone to offer us your detail information or you can just leave your message on our website. We will give you the best quotation ASAP.

Q3: What’s the procedure of trading?

A: Design drawing →Confirm drawing→Quotation→PI→ConfirmPI→Arrange 30% deposit→Manufacture→ QCinspect→ Paybalance→Shipping.

Q4: What is the biggest advantage of your product?

A: We use high-quality raw materials, strictly control the quality of production. We improve our product performance by improving our technology. These make our products more beautiful and have a longer life, lower cost of use.

Wise Link’s main products include clean room panels, clean room Aluminum frame/steel frame doors, clean room double glass windows, clean room dynamic pass boxes, FFU, clean room LED light, and so on.