Negative Pressure Weighing Booth is a type of partial purification equipment specifically designed for pharmaceutical, microbiological research, and scientific experiment areas. It provides a vertical unidirectional airflow, where part of the clean air circulates in the work area and the rest is discharged to the nearby area. This setup enables the work area to generate negative pressure, preventing cross-contamination and ensuring a high level of cleanliness in the environment.

The booth is ideal for weighing and packaging dust and reagents. It effectively controls the overflow and rise of dust, minimizing the inhalation hazards posed to humans while avoiding cross-contamination. Additionally, it protects the safety of both external environments and indoor personnel, ensuring compliance with high safety and cleanliness standards.

The Negative Pressure Weighing Booth offers exceptional scalability to meet the diverse needs of its users. Its modular design allows for seamless customization based on the workspace layout and specific operational requirements. Whether you’re working in a compact laboratory or a large pharmaceutical facility, this booth adapts effortlessly. As workflows evolve, the booth’s components can be reconfigured or upgraded, ensuring it remains a reliable solution for your operations. This flexibility makes it ideal for both small-scale research environments and high-volume production facilities.

Engineered for efficiency and convenience, the Negative Pressure Weighing Booth prioritizes user experience. The intuitive control panel and automatic fault detection systems simplify daily operations, reducing the need for extensive manual monitoring. Its advanced PLC system alerts users when filters require replacement, ensuring uninterrupted workflow and minimizing downtime. With noise levels kept at ≤70 dB, the booth provides a comfortable working environment, while its ergonomic design supports safe and efficient handling of materials. These features collectively enhance user confidence and satisfaction in managing critical tasks.

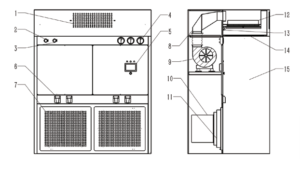

The Negative Pressure Weighing Booth is equipped with advanced functions to ensure optimal performance. The vertical unidirectional airflow maintains negative pressure in the work area, preventing cross-contamination. Its triple filtration system—comprising primary, medium, and HEPA filters—ensures superior air purity and compliance with Class A purification standards. The high-precision wind speed sensor and PLC control system stabilize airflow, while the UV sterilization lamp enhances sterilization. Fault detection, automatic alarms, and modular assembly make this booth a highly functional and reliable solution for contamination control in pharmaceuticals, research, and production.

Wise Link is renowned for delivering exceptional quality in cleanroom solutions, and the Negative Pressure Weighing Booth is no exception. Constructed from SUS 304 stainless steel, the booth combines durability with a sleek, modern design. Every component is designed to meet stringent industry standards, ensuring reliability and long-term performance. The quick-install filter structure and advanced control systems reflect Wise Link’s commitment to innovation and excellence. With a focus on user safety, efficiency, and environmental protection, Wise Link products consistently set the benchmark for quality in the cleanroom and laboratory sectors.

Wise Link’s main products include clean room panels, clean room Aluminum frame/steel frame doors, clean room double glass windows, clean room dynamic pass boxes, FFU, clean room LED light, and so on.