Welcome to the realm of modular cleanrooms, where precision meets innovation to uphold impeccable standards of cleanliness.

In this detailed exploration, we’ll delve into the essence of modular cleanrooms, unraveling their significance across diverse industries. From pharmaceuticals to electronics, these controlled environments play a pivotal role in safeguarding sensitive processes.

Let’s embark on a journey to demystify the concept of modular cleanrooms and understand their pivotal role in today’s technologically advanced world.

What Are Modular Cleanrooms

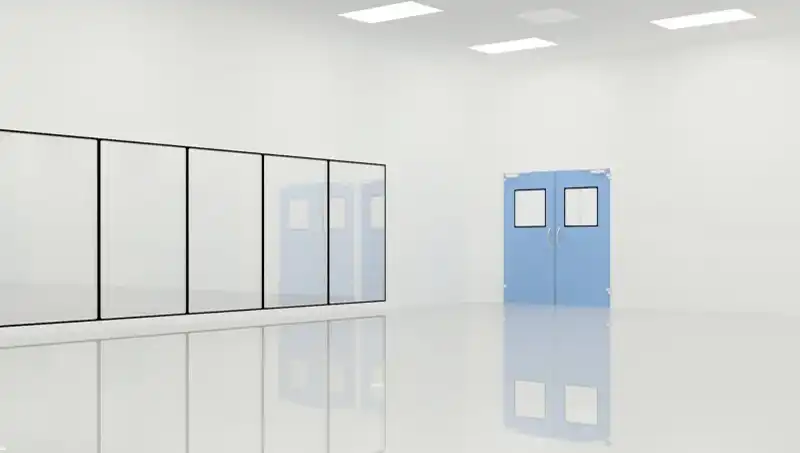

Modular cleanrooms are specialized enclosed spaces designed to maintain extremely high levels of cleanliness by controlling particulate contamination, temperature, humidity, and other environmental parameters. These cleanrooms are constructed using modular components that can be easily assembled, disassembled, and reconfigured according to specific requirements.

Components of a Modular Cleanroom

Within the confines of a modular cleanroom, several key components work synergistically to achieve optimal cleanliness. From high-efficiency particulate air (HEPA) filters to sophisticated HVAC systems, each element plays a crucial role in creating and maintaining a pristine environment.

Design Considerations

The design of a modular cleanroom is meticulously crafted to meet the specific requirements of its intended application. Factors such as airflow patterns, temperature, humidity control, and material compatibility are intricately woven into the design fabric to ensure seamless functionality.

Applications Across Industries

The versatility of modular cleanrooms transcends boundaries, finding application in an array of industries. From pharmaceutical manufacturing and biotechnology research to semiconductor production and aerospace engineering, these controlled environments serve as bastions of purity and precision.

Materials Used in Modular Cleanrooms

Modular cleanrooms are constructed using a variety of specialized materials carefully chosen to meet the stringent cleanliness and performance requirements of the controlled environment. Here are some common materials used in the construction of modular cleanrooms:

- Wall Panels: The walls of modular cleanrooms are typically constructed using rigid panels made of materials such as aluminum, steel, stainless steel, or composite materials like fiberglass reinforced plastic (FRP). These panels provide structural integrity while offering smooth, non-porous surfaces that are easy to clean and resistant to contamination.

- Ceiling Panels: Similar to wall panels, ceiling panels in modular cleanrooms are designed to provide a smooth, clean surface that minimizes the accumulation of dust and particulates. These panels are often made of materials like aluminum or steel and may feature integrated lighting fixtures, HEPA filters, or other components necessary for maintaining the cleanliness of the environment.

- Flooring Systems: The flooring of modular cleanrooms is typically constructed using materials that are durable, non-porous, and easy to clean. Common flooring materials include epoxy resin, vinyl tiles, or stainless steel. These materials offer resistance to chemicals, moisture, and microbial growth, ensuring a clean and hygienic environment.

- Doors and Windows: Doors and windows in modular cleanrooms are designed to provide secure access while maintaining the integrity of the controlled environment. These components may feature materials such as stainless steel, glass, or polycarbonate, depending on the specific requirements of the cleanroom.

- HVAC Systems: Heating, ventilation, and air conditioning (HVAC) systems are integral to the operation of modular cleanrooms, providing precise control over temperature, humidity, and air quality. These systems may include components such as HEPA filters, air handlers, ductwork, and control panels, all constructed using materials suitable for cleanroom environments.

- Lighting Fixtures: Proper lighting is essential for visibility and productivity in cleanroom environments. Lighting fixtures used in modular cleanrooms are designed to meet stringent cleanliness standards and may feature materials such as stainless steel or aluminum housings with shatterproof lenses.

- Filtration Systems: Filtration systems play a critical role in maintaining the cleanliness of modular cleanrooms by removing airborne contaminants. HEPA (High-Efficiency Particulate Air) filters are commonly used in cleanroom environments to achieve the desired level of air purity. These filters are constructed using specialized materials that trap particles as small as 0.3 microns in size.

The materials used in the construction of modular cleanrooms are carefully selected to ensure durability, cleanliness, and compliance with industry standards. By utilizing high-quality materials and precise engineering, modular cleanrooms provide the controlled environments necessary for a wide range of applications across various industries.

Advantages of Modular Cleanrooms

Modular cleanrooms offer a plethora of advantages that make them indispensable assets across various industries.

Let’s delve deeper into these benefits:

Flexibility in Design and Layout: One of the primary advantages of modular cleanrooms is their inherent flexibility. Unlike traditional cleanrooms, which often have fixed layouts, modular cleanrooms can be easily customized and adapted to suit specific requirements. This flexibility allows for the efficient utilization of space and the optimization of workflow processes. Whether it’s adding new equipment, rearranging workspace configurations, or accommodating changes in production needs, modular cleanrooms offer unparalleled flexibility.

Scalability: Another key advantage of modular cleanrooms is their scalability. These cleanrooms can be effortlessly expanded or downsized to match fluctuations in production volumes or research requirements. Whether there’s a need to increase manufacturing capacity or downsize operations, modular cleanrooms can adapt accordingly without the need for extensive construction or renovation. This scalability ensures that organizations can efficiently manage their resources and respond to changing market demands with agility.

Cost-Effectiveness: Modular cleanrooms are often more cost-effective than traditional stick-built cleanrooms. The modular construction approach reduces construction time, labor costs, and material expenses. Additionally, modular cleanrooms can be prefabricated off-site, minimizing disruptions to ongoing operations and reducing overall project timelines. These cost savings make modular cleanrooms an attractive option for businesses looking to optimize their capital expenditures while maintaining high-quality cleanroom environments.

Speed of Deployment: Time is of the essence in today’s fast-paced business environment, and modular cleanrooms offer a distinct advantage in terms of speed of deployment. Unlike conventional cleanroom construction, which can be time-consuming and disruptive, modular cleanrooms can be installed and operational in a fraction of the time. This rapid deployment ensures minimal downtime and allows organizations to expedite their production or research activities, bringing products to market faster and gaining a competitive edge.

Compliance with Regulatory Standards: Regulatory compliance is paramount in industries where cleanliness and contamination control are critical, such as pharmaceuticals, biotechnology, and healthcare. Modular cleanrooms are designed to meet stringent regulatory requirements and industry standards, ensuring adherence to quality, safety, and cleanliness guidelines. Whether it’s maintaining ISO classifications or complying with specific regulatory mandates, modular cleanrooms provide the assurance of regulatory compliance, mitigating risks and ensuring product integrity.

FAQs (Frequently Asked Questions)

How does a modular cleanroom differ from a traditional cleanroom?

A modular cleanroom offers greater flexibility and scalability compared to traditional cleanrooms. Its modular construction allows for easier installation, customization, and reconfiguration to suit changing requirements.

What industries benefit from modular cleanrooms?

A wide range of industries benefit from modular cleanrooms, including pharmaceuticals, biotechnology, electronics manufacturing, aerospace, healthcare, and research laboratories.

Can modular cleanrooms accommodate specific cleanliness standards?

Yes, modular cleanrooms can be tailored to meet various cleanliness standards, including ISO classifications such as ISO 14644 and specific industry regulations.

How are modular cleanrooms maintained and serviced?

Modular cleanrooms require regular maintenance and servicing to ensure optimal performance. This includes filter replacements, airflow calibration, and periodic cleaning of surfaces and equipment.

Are modular cleanrooms cost-effective compared to traditional cleanrooms? While the initial investment in modular cleanrooms may be higher, their flexibility and scalability often result in long-term cost savings. Additionally, modular cleanrooms can be more efficiently integrated into existing facilities, minimizing disruption and downtime.

What are the environmental benefits of modular cleanrooms?

Modular cleanrooms help minimize environmental impact by reducing energy consumption, optimizing resource utilization, and enhancing waste management practices.

Conclusion:

In conclusion, the concept of modular cleanrooms encapsulates the epitome of precision engineering and technological innovation. These controlled environments serve as sanctuaries of purity, safeguarding critical processes and products across diverse industries.

As we continue to push the boundaries of scientific and technological advancement, modular cleanrooms will undoubtedly remain indispensable allies in our quest for excellence.